Part cleaning machine

A cleaning machine and parts technology, applied in the field of cleaning machines, can solve the problems of unreasonable layout, large occupied space, and unfavorable utilization of the internal space of the factory building, etc., and achieve good heat preservation effect, high work efficiency, and reasonable layout of the body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

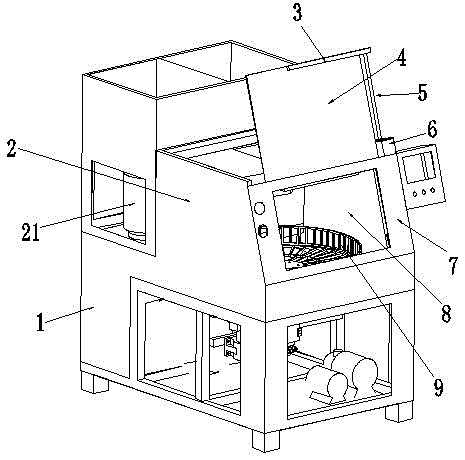

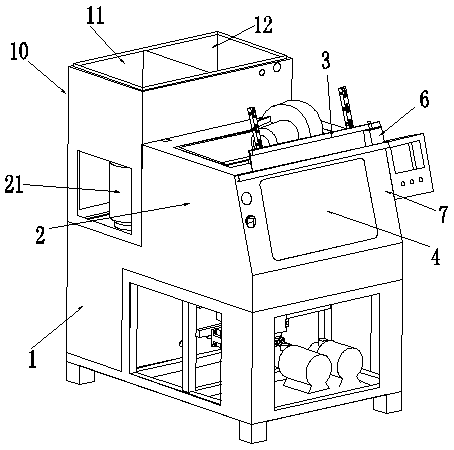

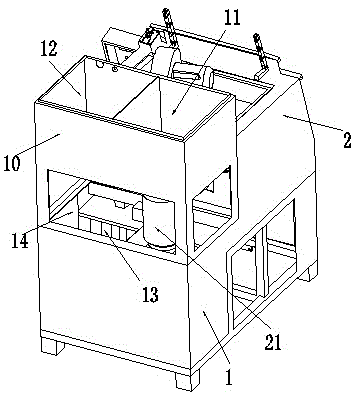

[0021] As shown in the figure, the structure of the parts cleaning machine includes a cleaning tank 2 and a liquid storage tank 1, and the cleaning tank 2 is located at the oblique top of the liquid storage tank 1. A power mechanism is provided below the cleaning box 2, and a cleaning frame 9 is arranged in the cleaning box 2. The power mechanism extends into the cleaning box 2 and is connected with the cleaning frame 9. The power mechanism is used to drive the cleaning frame 9 in the cleaning box 2. turn.

[0022] The bottom plate of the cleaning tank 2 and the top plate of the liquid storage tank 1 are generally connected as a whole. To be higher than the outer top surface of the liquid storage tank 1. In order to facilitate the flow of cleaning liquid, the inner bottom surface of the cleaning box 2 can be obliquely above the outer top surface of the liquid storage tank 1, and the inner bottom surface of the cleaning box 2 is inclined. A liquid flow channel is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com