Method for improving control accuracy of rolling force of HGC hydraulic cylinder of temper mill

A technology of control accuracy and hydraulic cylinder, applied in the direction of rolling force/roll gap control, etc., can solve the problems of large fluctuations in rolling force, increased control difficulty, and great influence on strip quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

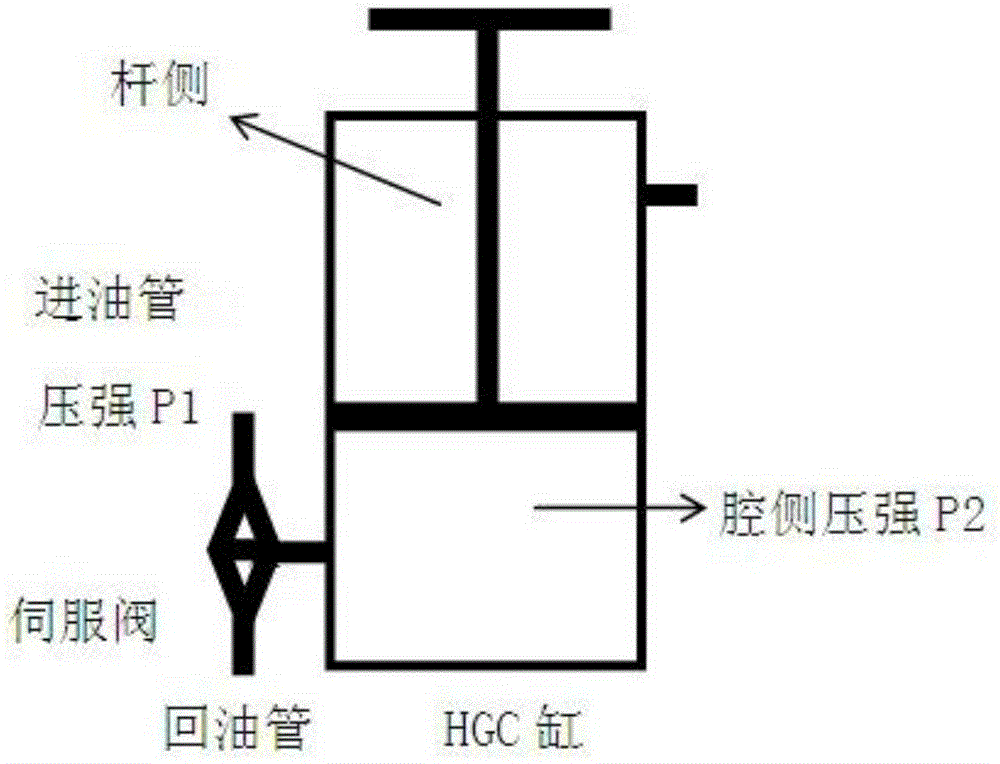

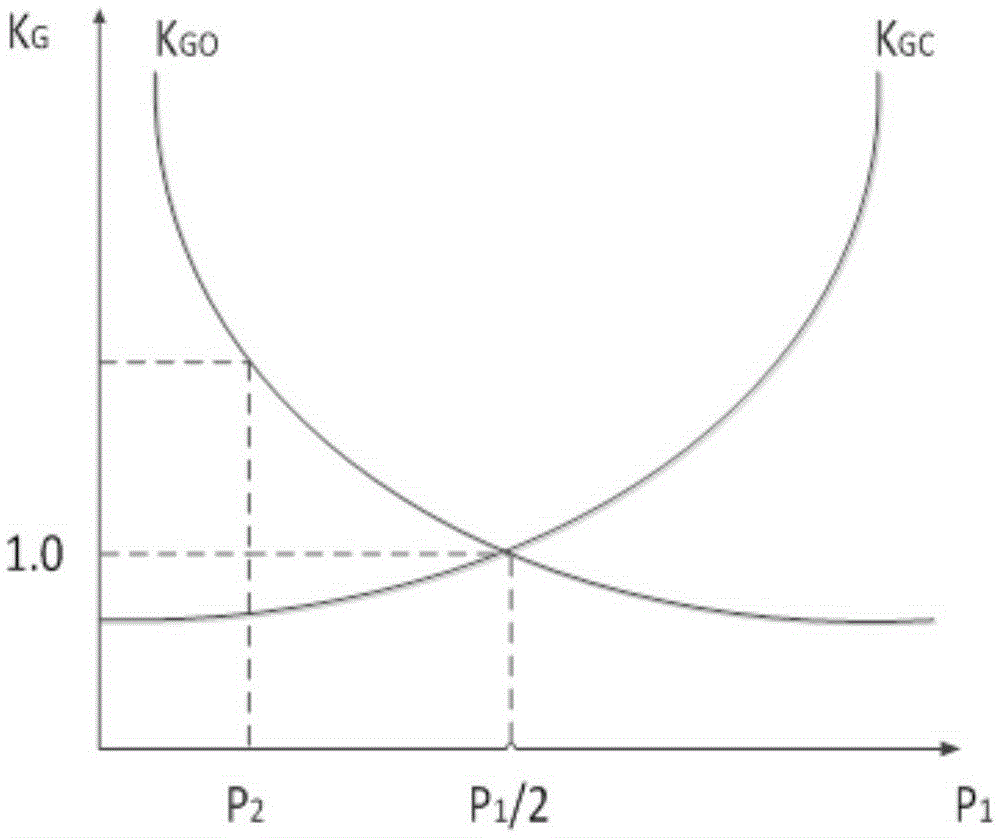

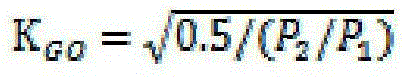

[0034] In a preferred embodiment, a method for improving the rolling force control accuracy of the HGC hydraulic cylinder of the skin pass mill includes the following steps: determining the pressure in the hydraulic cylinder; determining the pressure of the external pipeline; determining the pressure difference between the inside and outside of the hydraulic cylinder; according to The internal and external pressure difference of the hydraulic cylinder determined in step (3) pushes down the relationship between the opening of the HGC cylinder servo valve and the pressure, which is completed by the control device; the opening of the servo valve is controlled according to the relationship obtained in step (4), and the rolling force control is controlled. The linear output of the device is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com