Dust removal and purification device for numerically-controlled cutting machine

A purification device and cutting machine technology, applied in the direction of combined devices, chemical instruments and methods, metal processing machinery parts, etc., can solve the problems of waste of resources, cutting tools without recovery and purification, suffering from pneumoconiosis and cough, etc., and achieve simple structure, Excellent vacuum effect and good promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

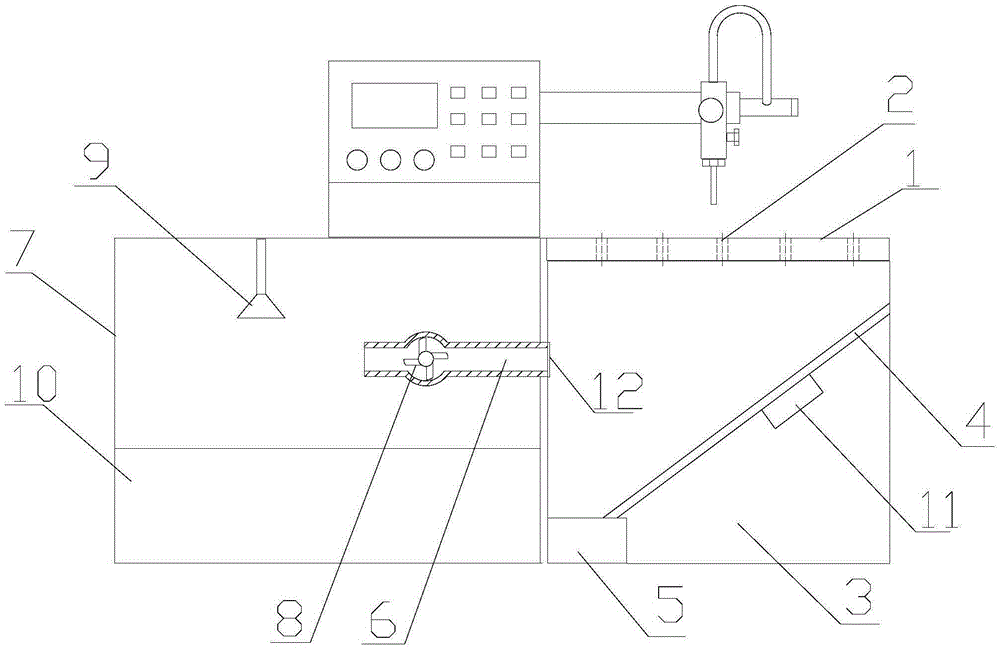

[0012] like figure 1 The shown dust removal and purification device for a CNC cutting machine includes: a working panel 1 arranged below the CNC cutting machine, a filter hole 2 is provided on the working panel 1, a coarse slag tank 3 is provided under the working panel 1, An inclined baffle plate 4 is arranged between the working panel 1 and the coarse slag tank 3. The design of the baffle plate 4 facilitates the falling of debris, and the bottom of the baffle plate 4 is provided with a detachable coarse slag collection box 5, which is convenient for regular cleaning. Collect the full coarse slag for processing, the side of the coarse slag tank 3 is also provided with a dust suction air duct 6, the inlet of the air duct communicates with the side wall of the coarse slag tank, and the outlet communicates with the fine slag tank 7, the dust suction air duct is provided with Fan 8, the upper part of the fine slag tank 7 is provided with an atomizing nozzle 9, which can make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com