Label papersqueezing machine

A press, label paper technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of low water content, high cost, easy to form paste, etc., and achieve complete dehydration, convenient production, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A marking paper press according to the present invention will be further described in detail through specific examples below.

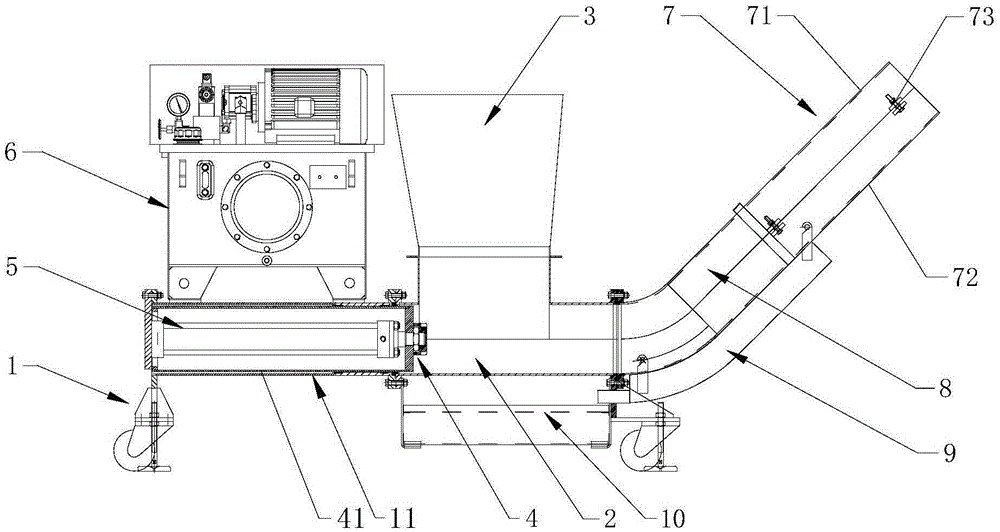

[0024] Such as figure 1 Shown, a kind of marking paper press machine comprises frame 1, and the first extruding barrel 2 is installed horizontally on the described frame 1, and the downstream end of the first extruding barrel 2 is provided with discharge port, and described first A hopper 3 is installed above the extrusion cylinder 2, and the first extrusion cylinder 2 communicates with the inside of the hopper 3. The first extrusion cylinder 2 is provided with a number of liquid outlet holes. An extruding part 4 is movable installed, and the shape and size of the extruding part 4 are adapted to the first extruding cylinder 2, and the extruding part 4 is driven by a linear power device.

[0025] In the present embodiment, the paper marking press also includes a second extrusion cylinder 8, which is connected to the downstream end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com