Misplaced bottle pushing device and bottle square array anti-falling method

A bottle and phalanx technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problems of increasing costs, affecting the efficiency of conveyor belt conveying, packaging line packaging efficiency, and bottle falling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below:

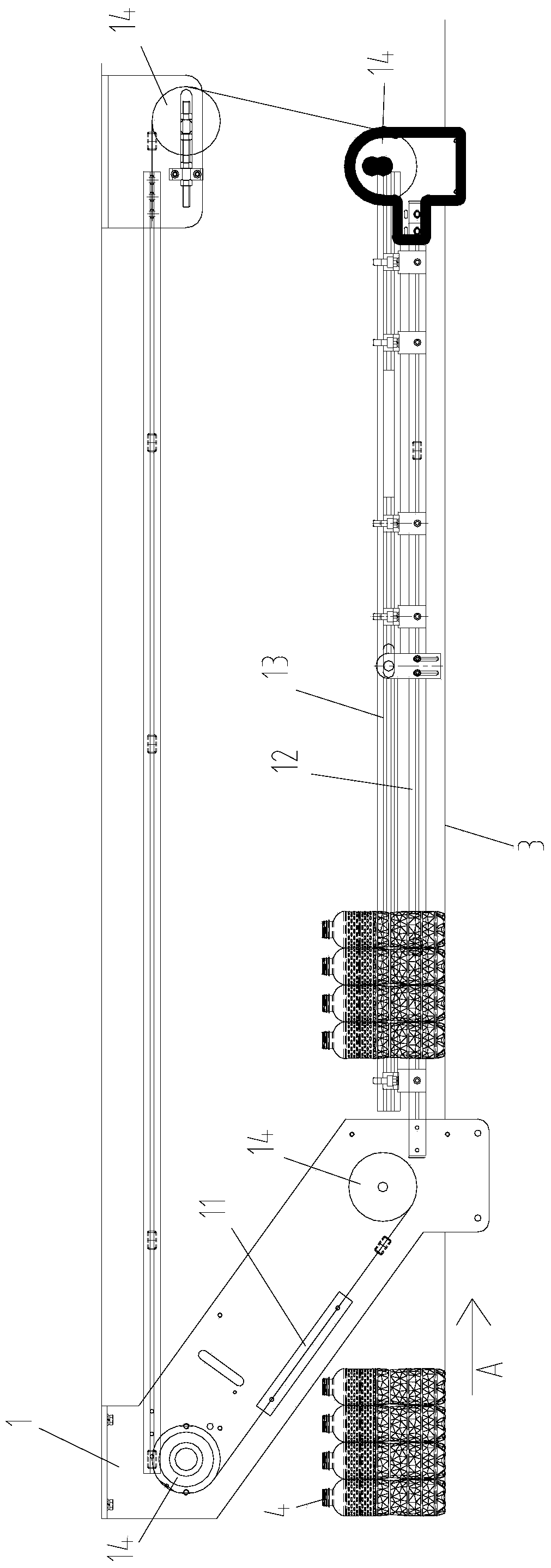

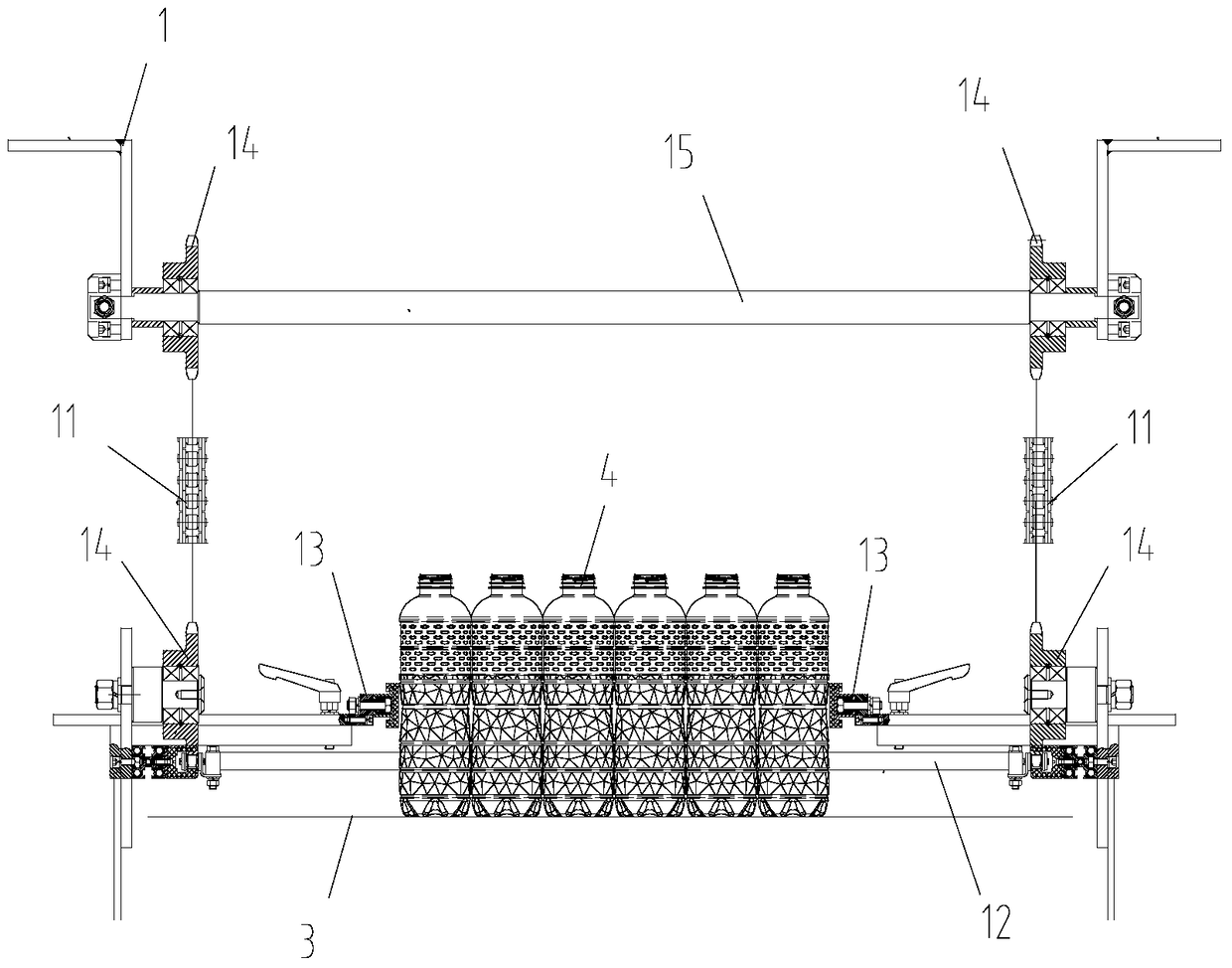

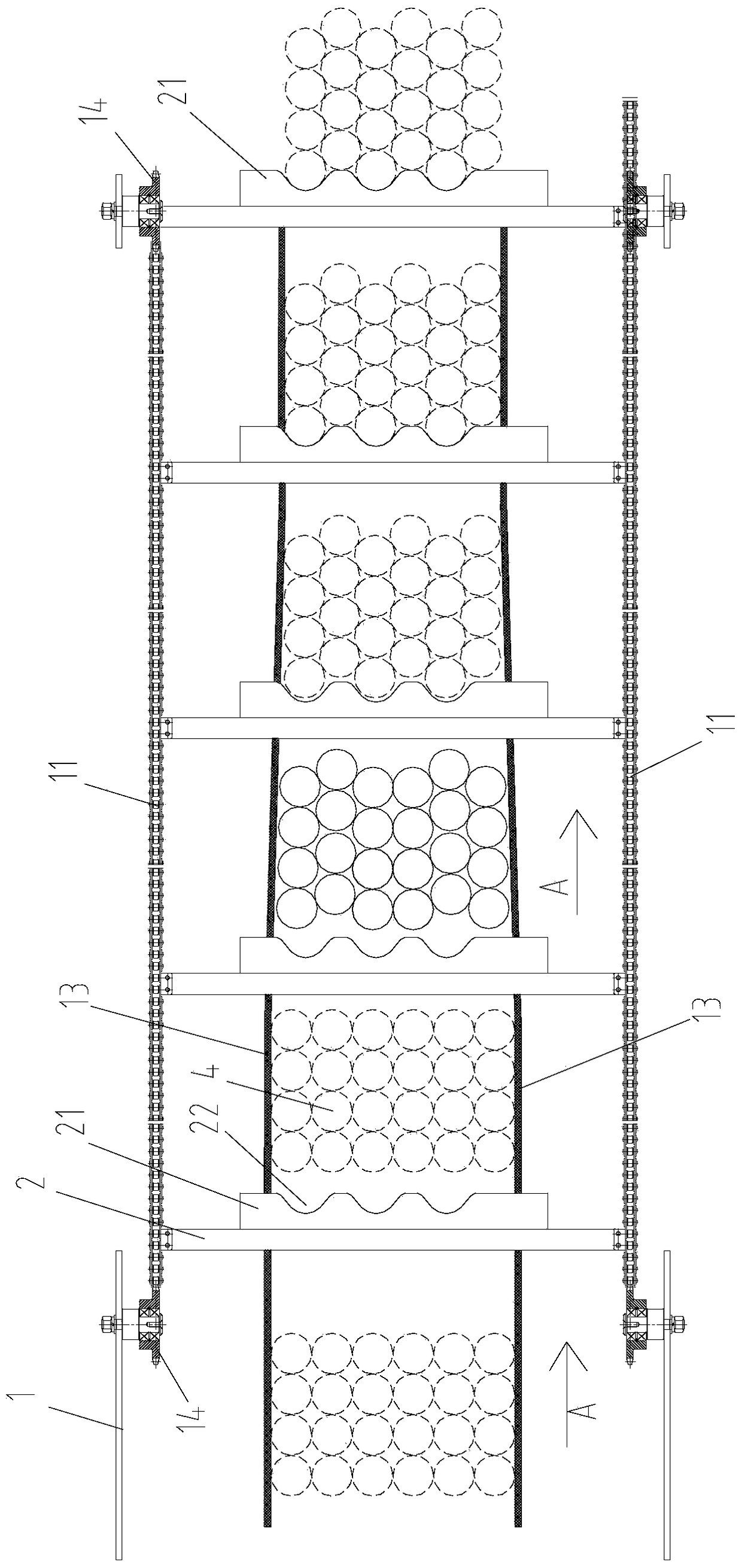

[0025] Such as Figure 1-3 As shown, it is a misplaced bottle pushing device, which includes a main body frame 1 and a plurality of bottle pushing rods 2, and the main body frame 1 straddles the conveying bottle matrix 4 (in this embodiment, a 4×6 bottle matrix) On the belt 3, the conveyor belt 11 that circulates is set around the main frame 1; a plurality of bottle push rods 2 are arranged on the conveyor belt 11, and the conveyor belt 11 drives a plurality of bottle push rods 2 to circulate up and down on the main frame 1, pushing One end surface of the bottle rod 2 is provided with a plurality of grooves 22 adapted to the bottle body of the bottle, the depth of the grooves 22 is less than or equal to the maximum radius of the bottle body, and the distance between two adjacent grooves 22 is smaller than that of the bottle. Twice the maximum diameter of the bottle body; when the bottle push rod 2 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com