Cantilever type hydraulic lifting bi-directional belt conveyor

A hydraulic lifting, two-way conveying technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of V-belt slippage, belt conveyor can not effectively extend into the wagon, conveyor straddle collapse and other problems, to prevent slippage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further description of the utility model in conjunction with the drawings:

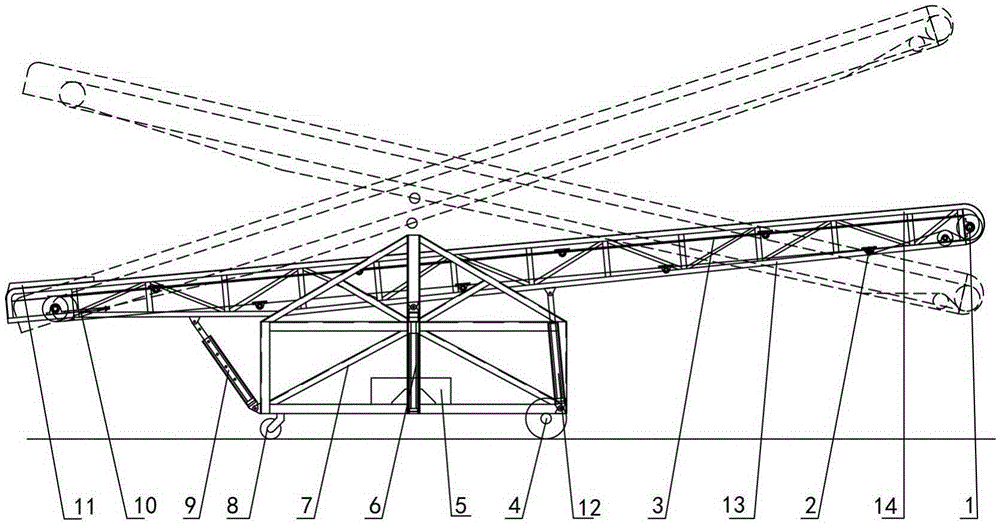

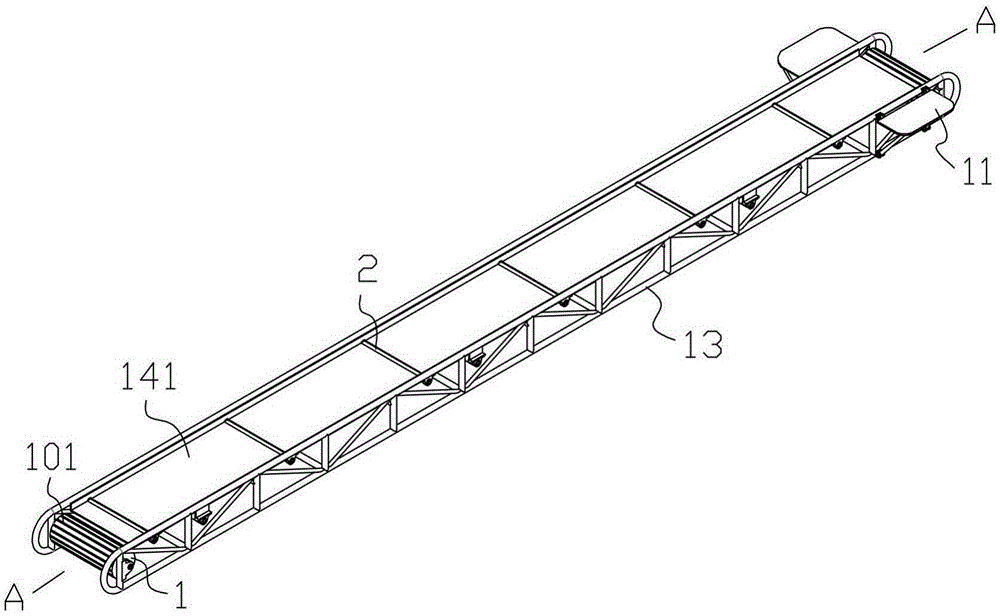

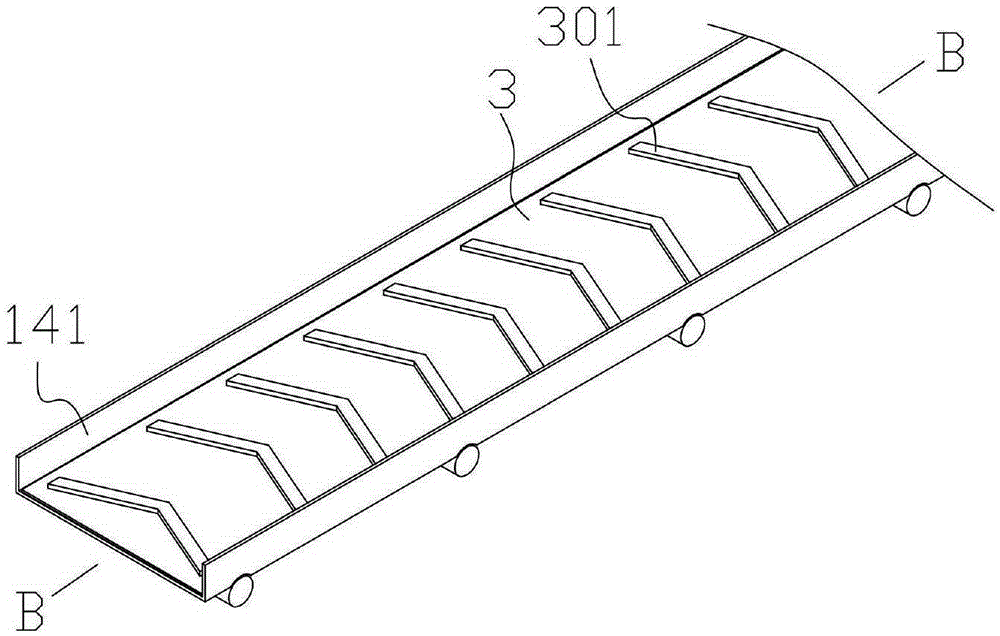

[0022] In the picture: electric drum 1, idler 2, conveyor belt 3, rubber roller 4, hydraulic oil tank 5, first hydraulic cylinder 6, movable support 7, universal roller 8, safety rod 9, tension device 10, movable springboard 11 , Second hydraulic cylinder 12, frame 13, wear-resistant rubber 101, engraved horizontal strip 102, anti-skid iron plate 111, support rod 112, protrusion 301, steel groove 141, opening 142, positioning sleeve 901, positioning rod 902, positioning 孔903.

[0023] Such as Figure 1 to 9 As shown, the cantilever hydraulic lifting belt two-way conveyor includes a movable support 7 and a conveying mechanism. A rubber roller 4 and a universal roller 8 are installed at the lower end of the support 7, and it also includes a safety rod 9, a first hydraulic cylinder 6 and a second hydraulic Cylinder 12, the conveying mechanism is connected to the mobile support 7 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com