Stacking and bundling production line for special-shaped cigarettes and production method

A production method and technology of a production line, applied in the directions of bundling objects, packaging/bundling articles, object stacking, etc., can solve problems such as improving production efficiency, unfavorable enterprises, and low efficiency, so as to reduce labor intensity, improve production efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

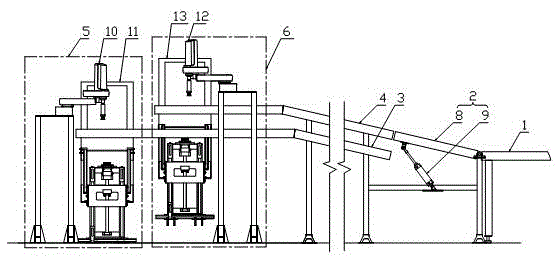

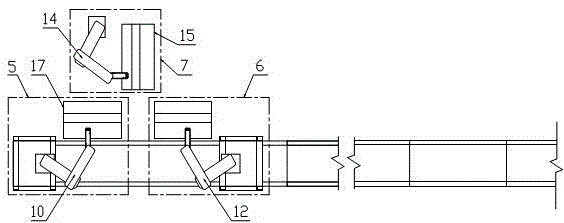

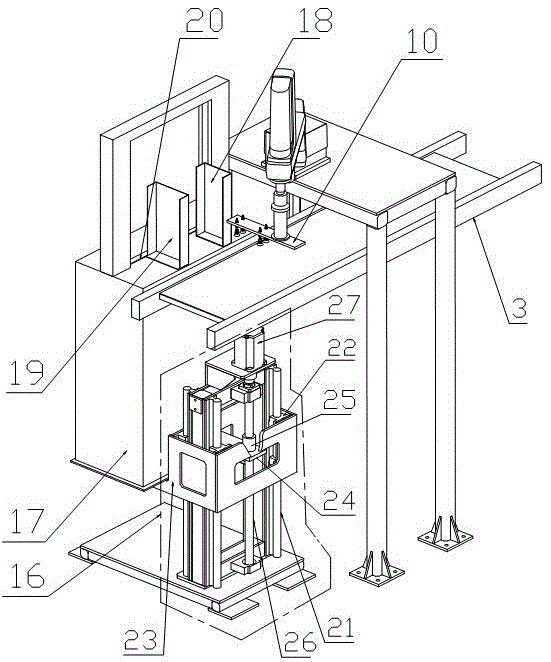

[0025] Example 1. A special-shaped cigarette stacking and bundling production line, which is composed of Figure 1-3As shown, it includes a main road conveyor belt 1, the main road conveyor belt 1 is connected with the smoke distribution device 2, the smoke distribution device 2 is connected with the first branch conveyor belt 3 or the second branch conveyor belt 4, and the first branch conveyor belt 3 is connected with the first longitudinal conveyor belt. The palletizing and binding device 5 is connected, the second branch conveyor belt 4 is connected with the second longitudinal palletizing and binding device 6, and the horizontal palletizing and binding device 7 is arranged between the first vertical palletizing and binding device 5 and the second longitudinal palletizing and binding device 6 The smoke distribution device 2 includes a smoke distribution conveyor belt 8, one end of the smoke distribution conveyor belt 8 is hinged with the main road conveyor belt 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com