Practical cloth dyeing device

A practical technology for dyeing cloth, applied in the field of dyeing and finishing machinery, which can solve the problems of uneven dyeing, poor firmness of dyed cloth, and difficult to clean up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

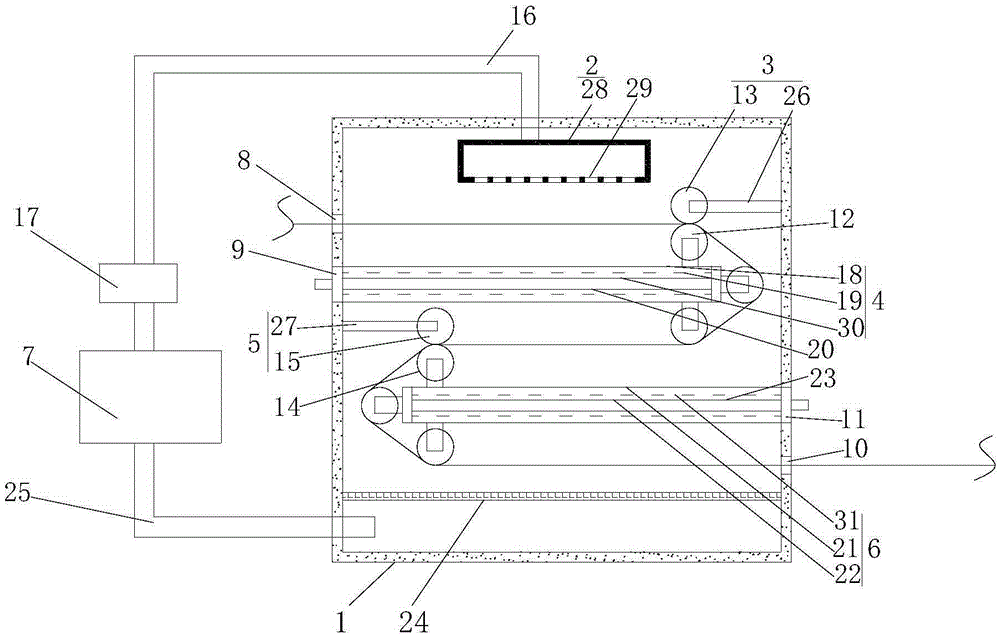

[0022] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a practical cloth dyeing device proposed by the present invention.

[0023] refer to figure 1 , a kind of practical cloth dyeing device that the present invention proposes, comprises casing 1, spraying device 2, the first pressure roller device 3, the first filter device 4, the second pressure roller device 5, the second filter device 6, guiding wheel and dye tank 7;

[0024] A side wall of the casing 1 is provided with a cloth inlet 8 and a first opening 9, the cloth inlet 8 is close to the top wall of the casing 1, the first opening 9 is located below the cloth inlet 8, and on the opposite side wall of the above-mentioned side wall of the casing 1 There is a cloth outlet 10 and a second opening 11, the cloth outlet 10 is close to the bottom wall of the casing 1, the second opening 11 is located above the cloth outlet 10, the height of the first opening 9 is higher than the height of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com