Pile block movable platform steel pipe pile driving construction method

A construction method and technology of steel pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficulty in ensuring piling accuracy, large wave influence, frequent parking, etc., to achieve easy control and reduce the impact of waves , the effect of moving forward conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The construction method of the pile top movable platform steel pipe pile designed by the present invention comprises the following steps:

[0032] Step 1: Set up multiple rows of steel pipe piles 1 (such as Image 6 shown);

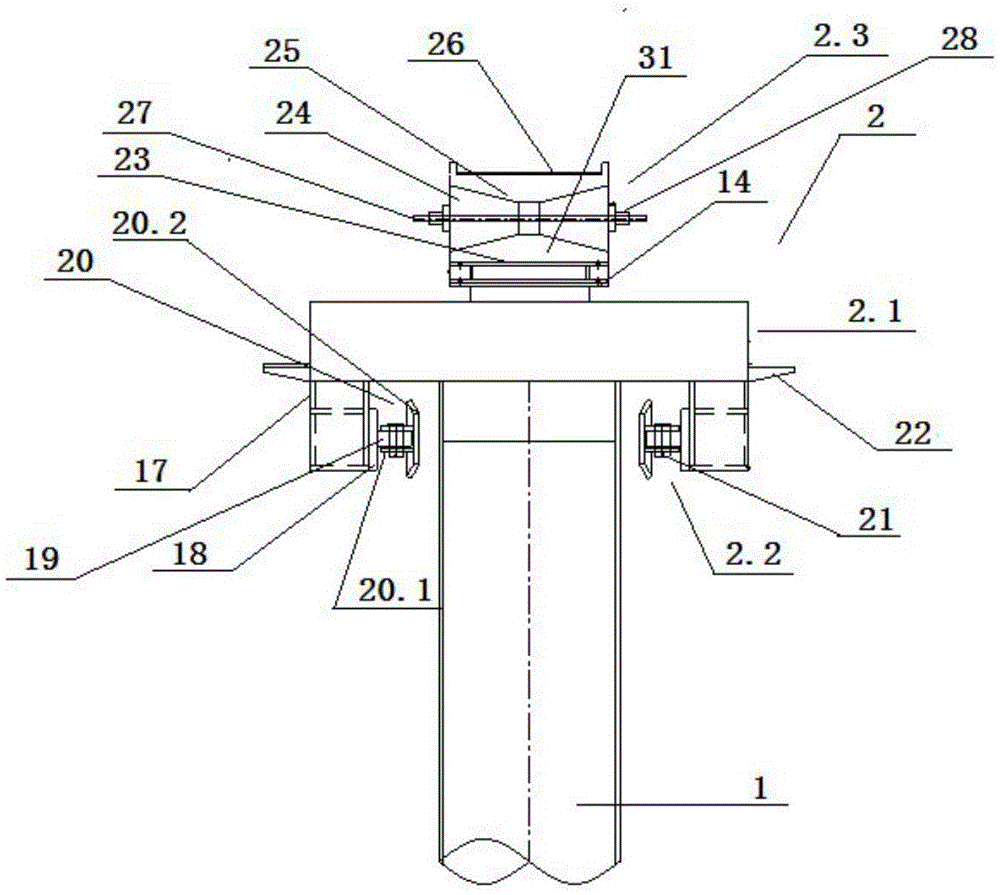

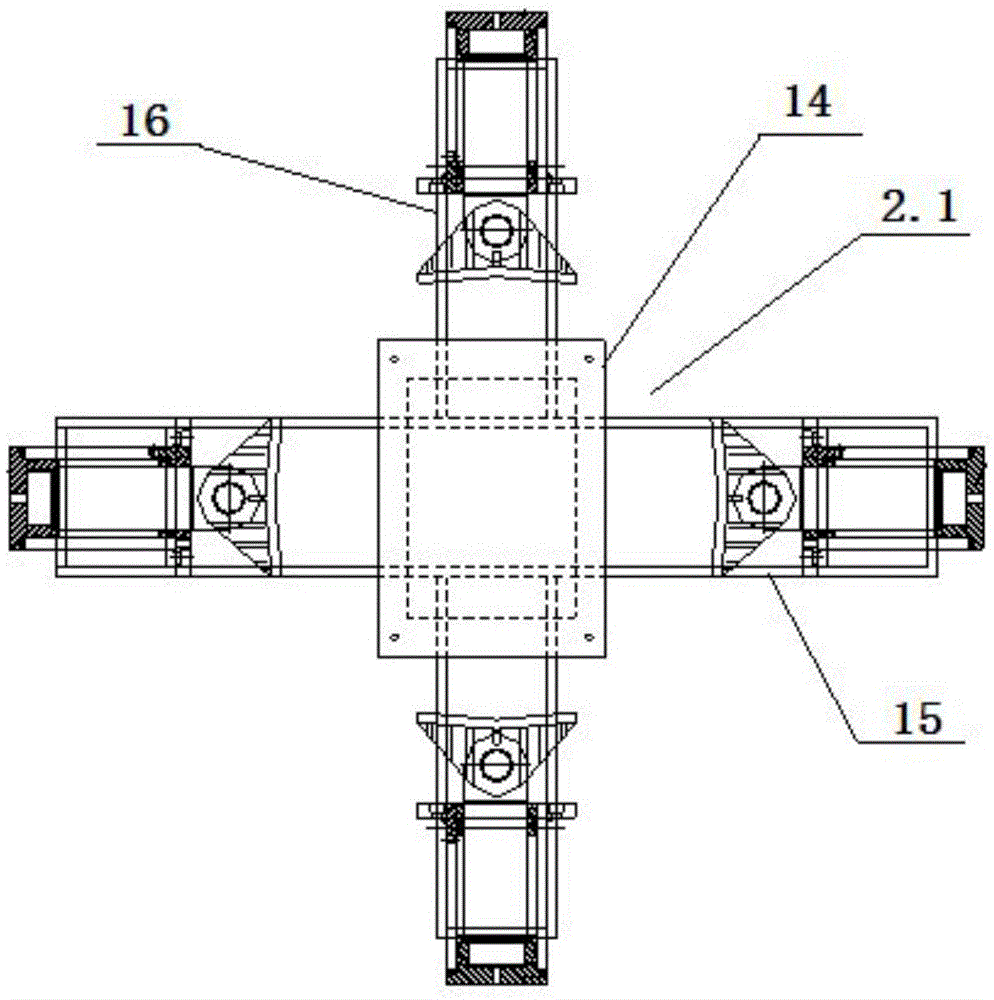

[0033] Step 2: Select continuous three rows of steel pipe piles 1 according to construction needs, install an elevation adjustment device 2 on the top of the pile, and operate the elevation adjustment device 2 to clamp the top of the steel pipe pile 1 (such as Image 6 shown);

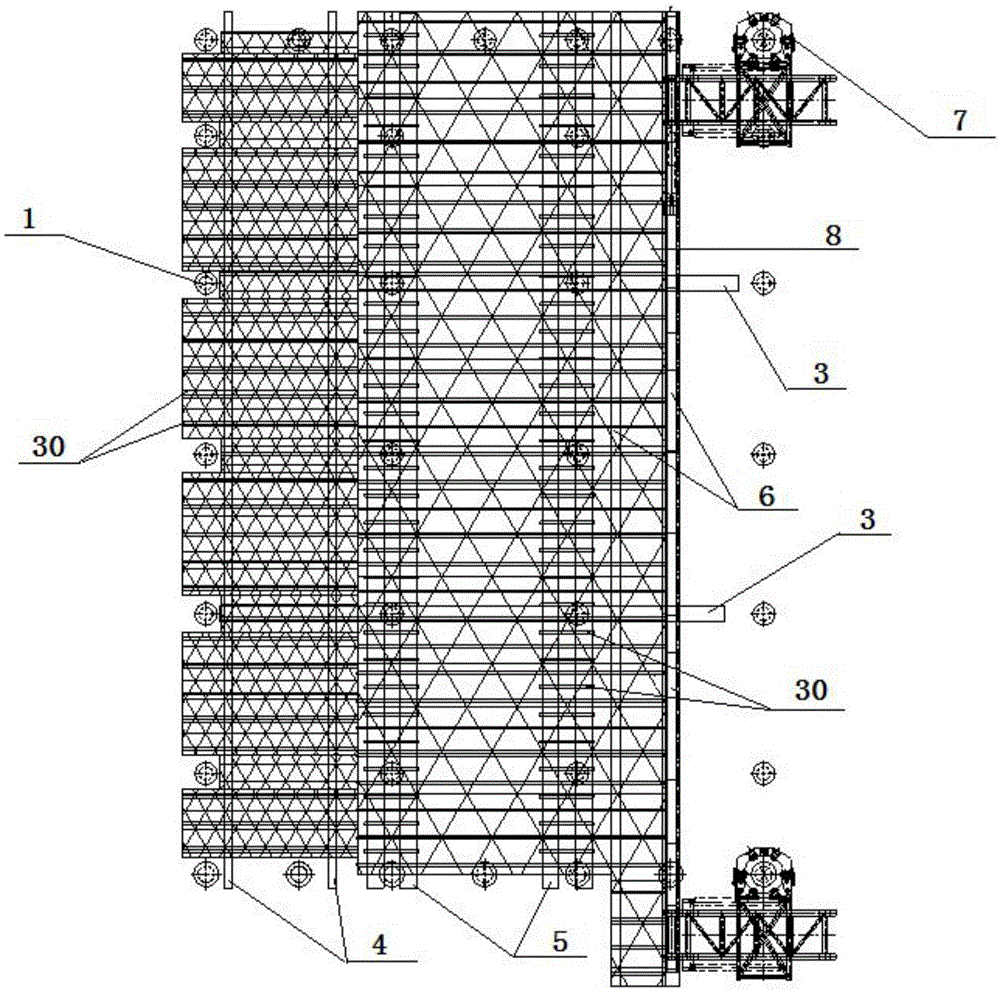

[0034] Step 3: Build the platform running track 3 on the top of the last two rows of steel pipe piles 1 located in the moving direction of the platform, so that the axis direction of the running track 3 is the same as the moving direction of the platform (such as figure 1 , Image 6 shown);

[0035] Step 4: Set up the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com