Independent retarder in front of box

A retarder and fixed wheel technology, applied in the direction of brake type, hydraulic resistance brake, mechanical equipment, etc., can solve the problem that the braking effect is not very obvious, and achieve a simple structure, strong applicability and high braking safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Due to the excessive braking load of large-tonnage trucks and large passenger cars, there will be thermal decline of the braking performance of the brakes, which will seriously affect the braking safety of the vehicles. Domestic tractors mainly water the brake pads when going downhill. It is not a very obvious problem. The present invention proposes an independent retarder in front of the box, which is installed between the engine and the gearbox to play the role of auxiliary braking.

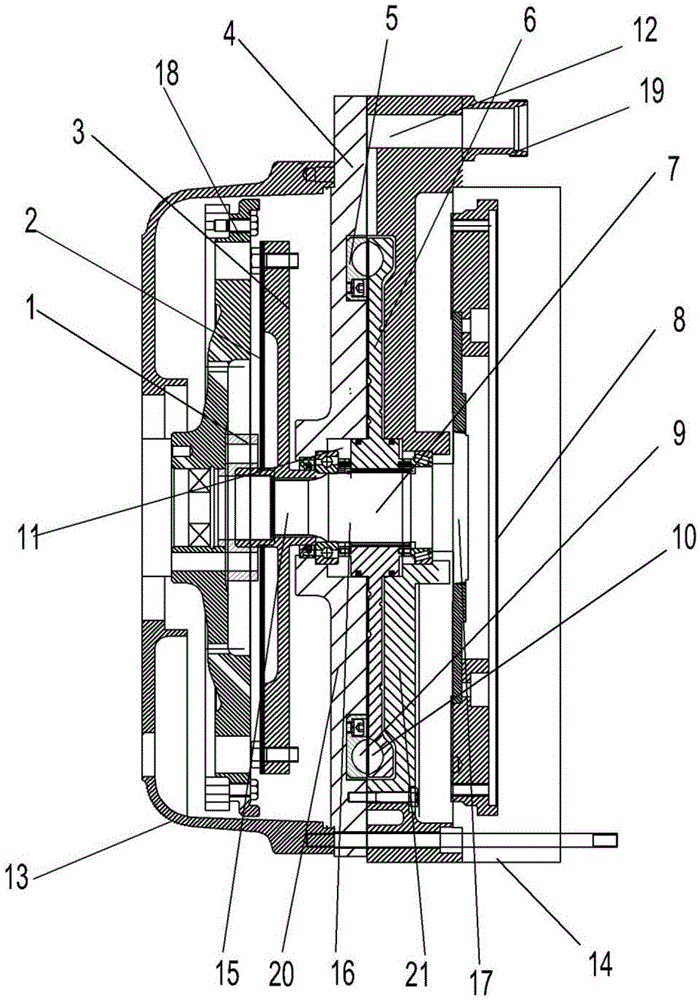

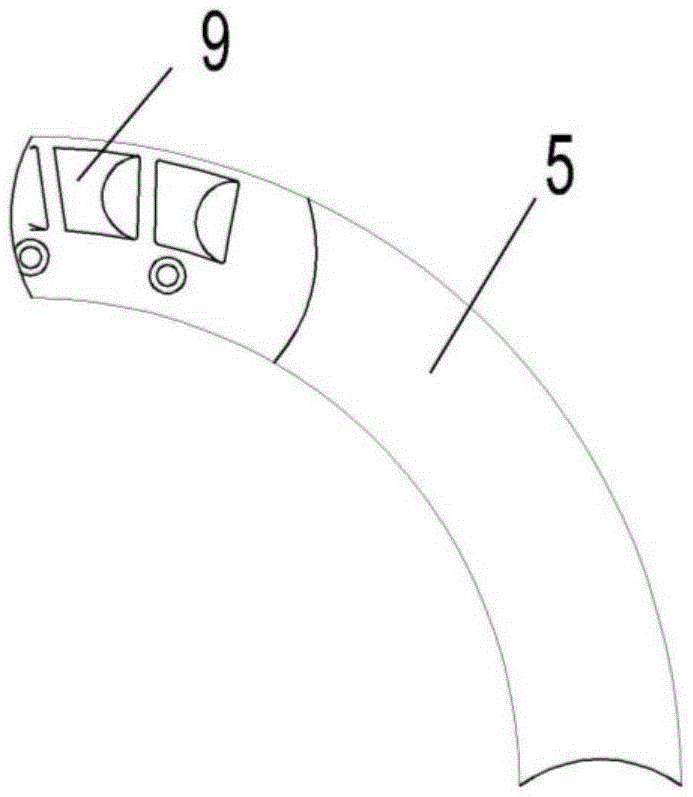

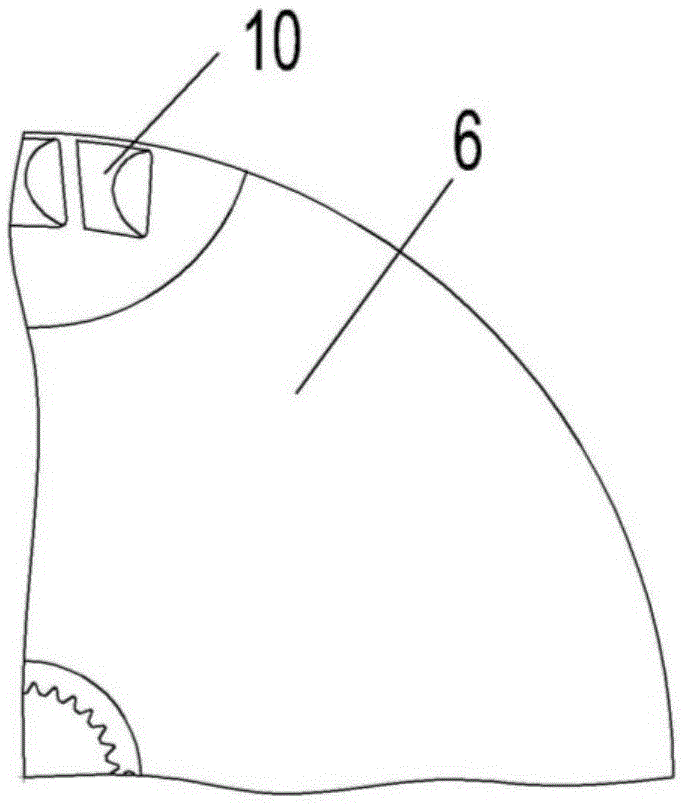

[0021] Attached below figure 1 , figure 2 and image 3 The structure of the present invention is described:

[0022] An independent retarder in front of the box, including a connecting hub 1, a flexible input plate 2, an input disc 3, a retarder housing 4, a retarder fixed wheel 5, a retarder moving wheel 6, an output shaft 7 and a flywheel 8;

[0023] like figure 2 As shown, the fixed wheel 5 of the retarder is an annular structure, and a plurality of first grooves 9 are evenly op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com