Overload protecting device for transmission element of cutting part of coal mining machine

A shearer cutting part, overload protection technology, applied in the direction of transmission, mechanical equipment, slip coupling, etc., can solve the problems of short life, overload, small transmission torque, etc. The effect of high efficiency and transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

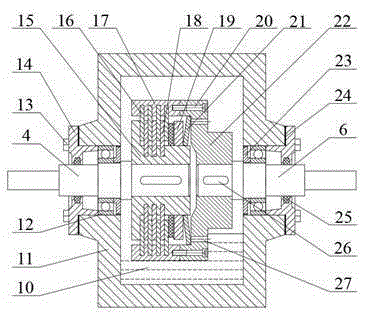

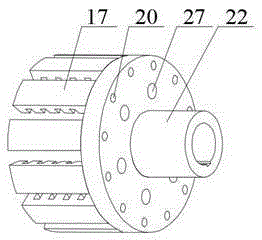

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] The invention is attached figure 2 as a basis, with figure 2 Front, rear, left, right, upper, lower, center, end face, inner side of the present invention are front, rear, left, right, upper, lower, center, end face, inner side. It should be noted that the relative arrangement, numerical values, etc. of components set forth in the present embodiment are not limited to the scope of the present invention unless specifically stated otherwise.

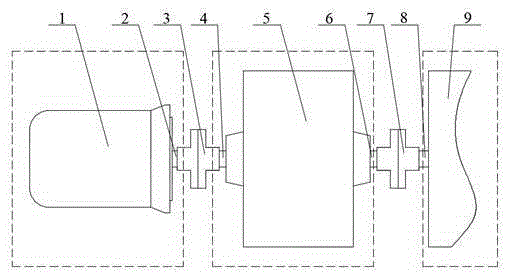

[0031] Such as figure 1 As shown, an overload protection device for the transmission element of the cutting part of the shearer, which includes:

[0032] Cutting motor 1, friction torque limiter 5 for overload protection and cutting reducer 9;

[0033] The input shaft 4 of the friction torque limiter 5 is connected with the motor shaft 2 of the cutting motor 1 through the coupling I3, and the output shaft 6 of the friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com