A device for suppressing pipe wall vibration and nozzle eddy current during jet flow in a water-filled pipe

A technology for water pipes and pipes, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve problems such as vibration and nozzle eddy current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

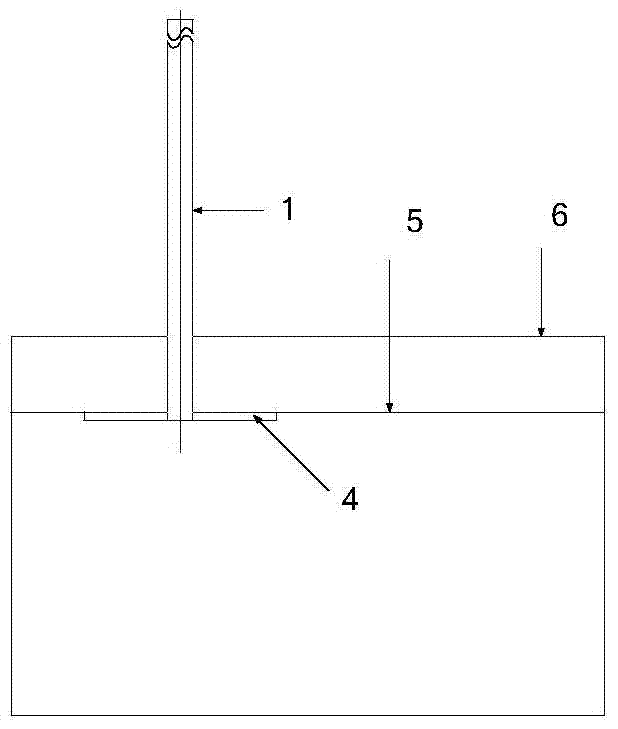

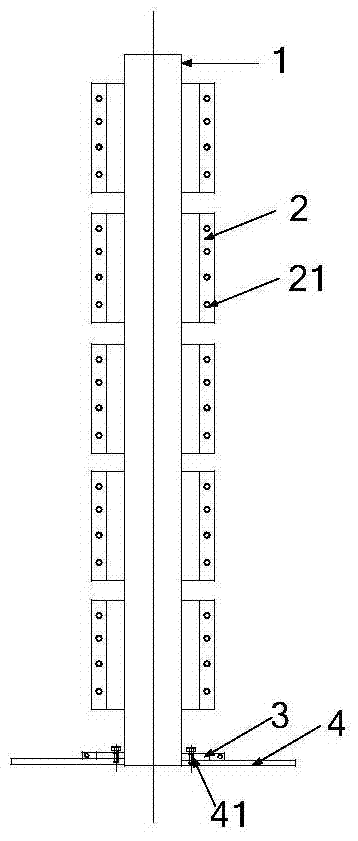

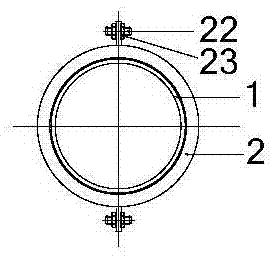

[0018] combine Figure 1 to Figure 5 , a device for suppressing the vibration of the pipe wall and the eddy current of the nozzle when the water-filled pipeline is jetted, including the water-filled pipeline 1, the vibration damping box 2, the nozzle clamp 3, the baffle 4, and the two vibration damping boxes 2 are a group of The studs 22 and nuts 23 are used to fix the body of the water-filled pipeline 1, the nozzle clamp 3 is fixed to the vicinity of the nozzle of the water-filled pipeline 1 by the studs 32 and the nuts 33, and the baffle 4 is fixed by the bolts 41. At the mouth of the water filling pipe 1.

[0019] The water filling pipe 1 is a round stainless steel pipe with an inner diameter of 88mm, an outer diameter of 108mm and a length of 2000mm. One end of the water filling pipe 1 is connected to the jet source, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com