Biomass gas and carbon co-production boiler

A biomass and boiler technology, applied in the field of boilers, can solve the problems such as the inability of equipment to operate normally, the difficulty in ensuring the quality of fixed carbon, and the bulky and bulky gasifier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

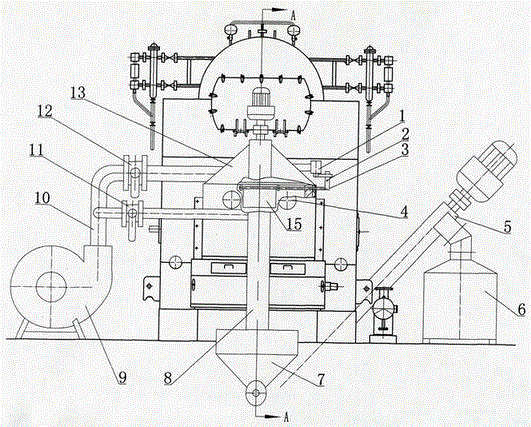

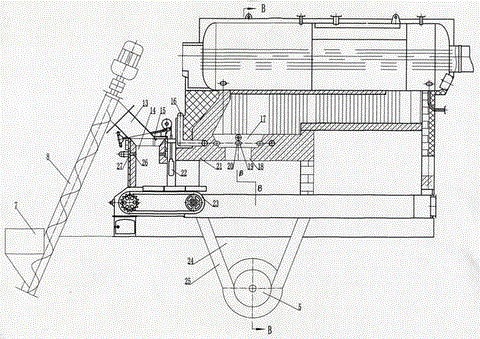

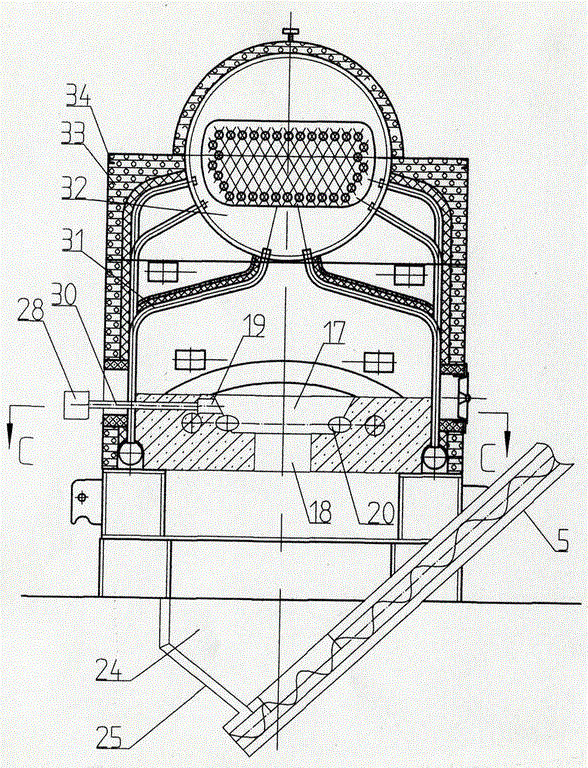

[0011] The biomass steam-charcoal co-production boiler of the present invention can be made by transforming the original coal-fired boiler, or a newly designed biomass steam-charcoal co-production boiler can be adopted. The former uses the original chain grate, boiler heating body and fan, etc., which reduces equipment costs, and is especially suitable for the transformation of coal-fired boilers, while the latter is suitable for new biomass-gas-charcoal co-production boilers.

[0012] The transformation of the coal-fired boiler into a biomass steam-charcoal co-production boiler is described in detail. First, the length of the original chain 23 grate is changed to a specification suitable for the required length, and the body base of the gasification chamber 14 is set on the chain grate. On one end, the gasification chamber body is fixed on the base of the gasification chamber body, the upper part of the gasification chamber is provided with an air gasification agent air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com