Measuring and adjusting device for pressing wheel arm assembly of textile machinery

A technology of adjusting device and mechanical pressure, which is applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of light labor of operators, affecting product quality and efficiency, and low production efficiency, etc. The effect of repeating verification testing, improving product quality and production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

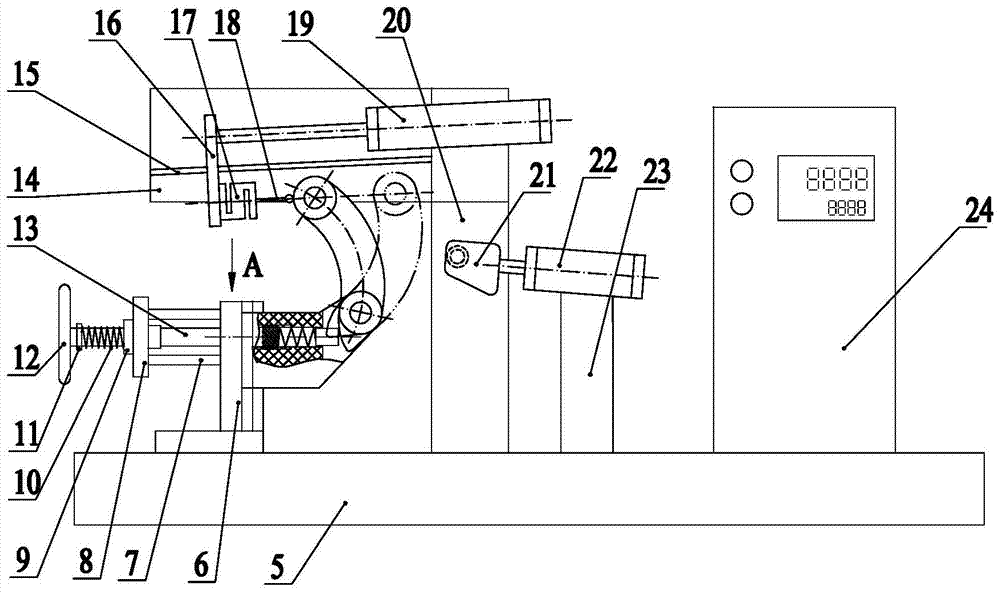

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0022] As shown in the figure: the force measuring adjustment device of the textile machinery pressure wheel arm assembly in the embodiment is mainly composed of a base 5, a fixed bracket 6, a pole 7, a mounting plate 8, a guide seat 9, a spring 10, a limit ring 11, a hand Wheel 12, polished rod 13, guide rail mounting plate 14, linear guide rail 15, connecting plate 16 load cell 17, ejector rod 18, cylinder 19, feed bracket 20, reset push head 21, reset cylinder 22, reset bracket 23 and control box 24 and so on.

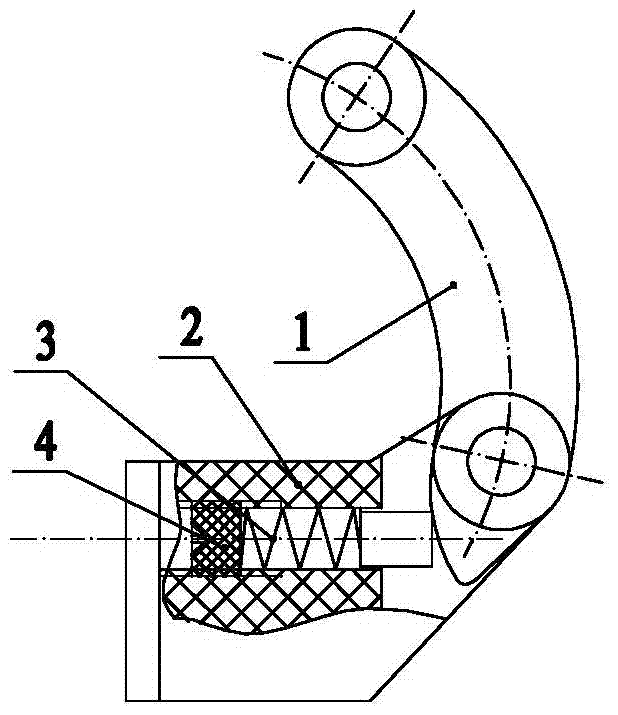

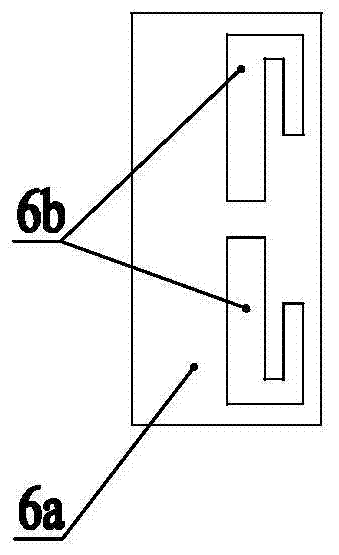

[0023] Such as figure 2 As shown, the fixed bracket 6 is fixed on the base 5, and the fixed bracket 6 is used to fasten the support arm 2 of the roller arm assembly; the feed bracket 20 is fixed on the base 5, and the constant speed feed mechanism Installed on the feed bracket 20, the load cell 17 is connected to the feed moving part of the consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com