Key testing mechanism

A testing mechanism and button technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of unquantifiable button comfort, misjudgment of defective products, and failure of buttons to be detected, etc., to achieve Convenient quality control, good effect of flexible mobile inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

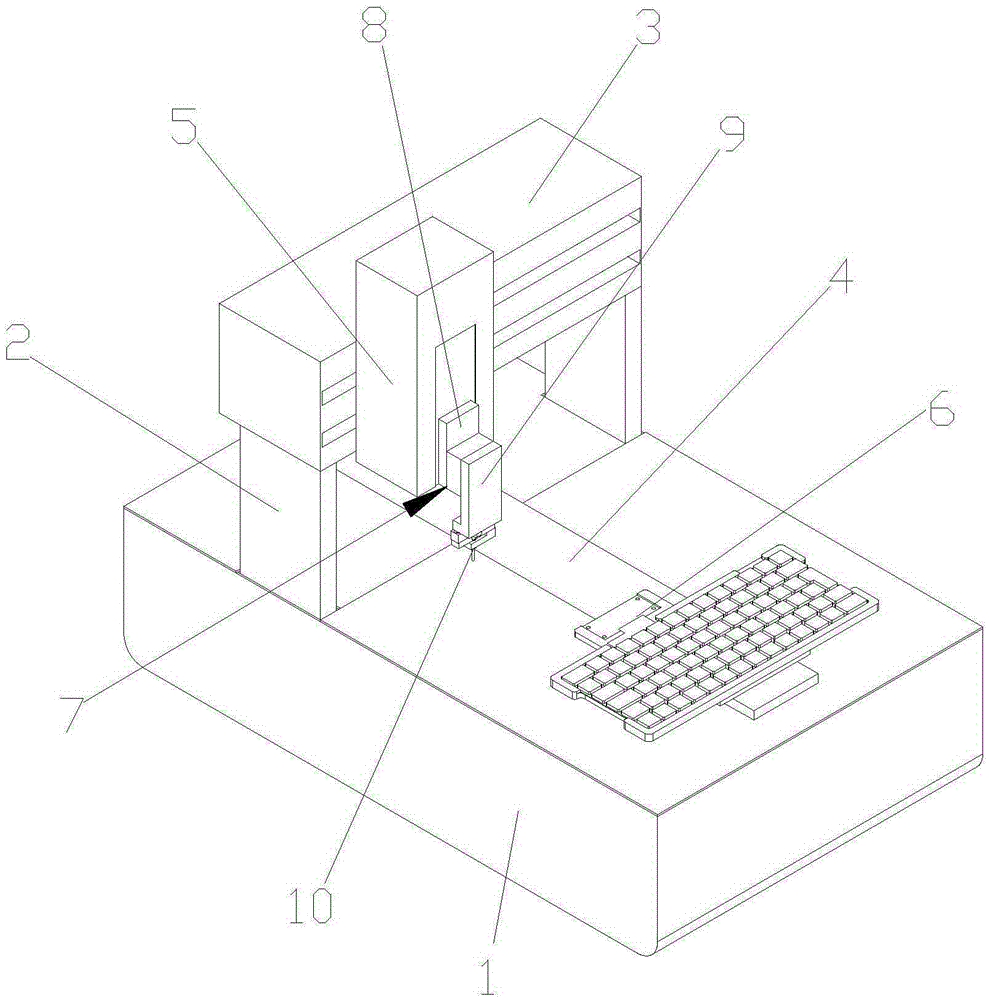

[0012] attached figure 1 It is a kind of button testing mechanism according to the present invention, comprising a workbench 1, a gantry support 2, an X-axis motion mechanism 3, a Y-axis movement mechanism 4, a Z-axis movement mechanism 5 and a product carrier 6; the gantry support 2 and The Y-axis motion mechanism 4 is installed on the workbench 1; the X-axis motion mechanism 3 is arranged on the gantry support 2; the Z-axis motion mechanism 5 is installed on the X-axis motion mechanism 3; the product carrier 6 is installed On the Y-axis motion mechanism 4; the Y-axis motion mechanism 4 can move back and forth on the workbench 1; the Z-axis motion mechanism 5 can move left and right on the X-axis motion mechanism 3; on the Z-axis motion mechanism 5 A detection module 7 is also provided; the detection module 7 includes a moving support plate 8, a fixed support 9 and a load cell 10; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com