Coaxial pathway testing device of base

A technology of access test and base, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of complicated test process, time-consuming and labor-intensive, etc., and achieve the effect of simple test process, saving labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

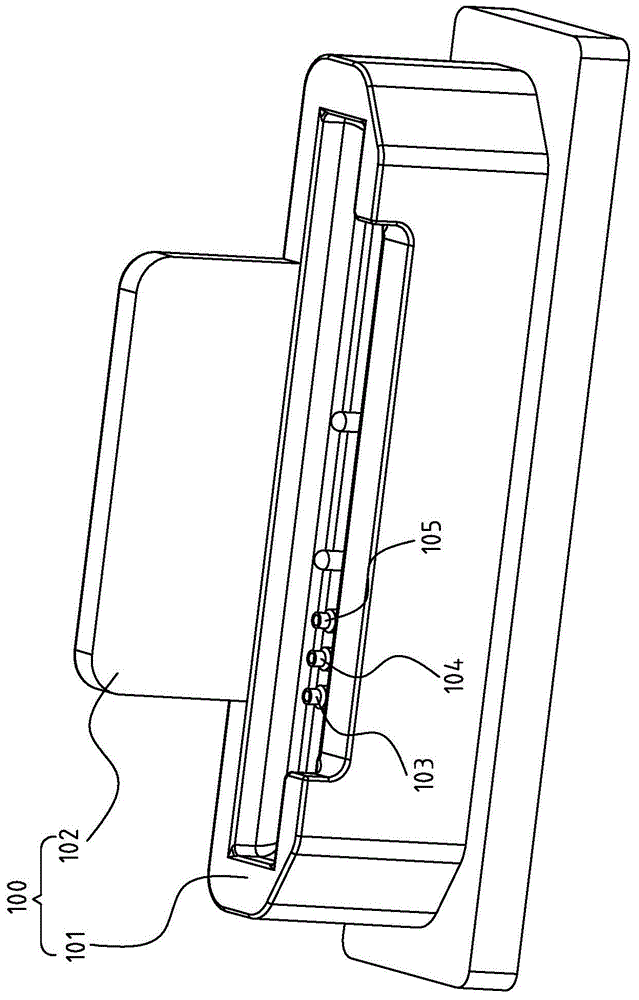

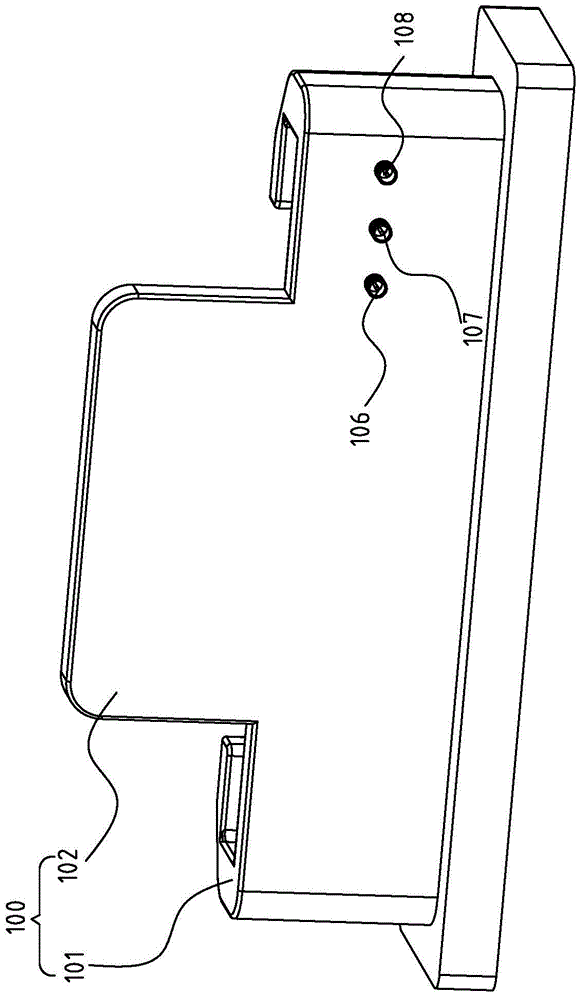

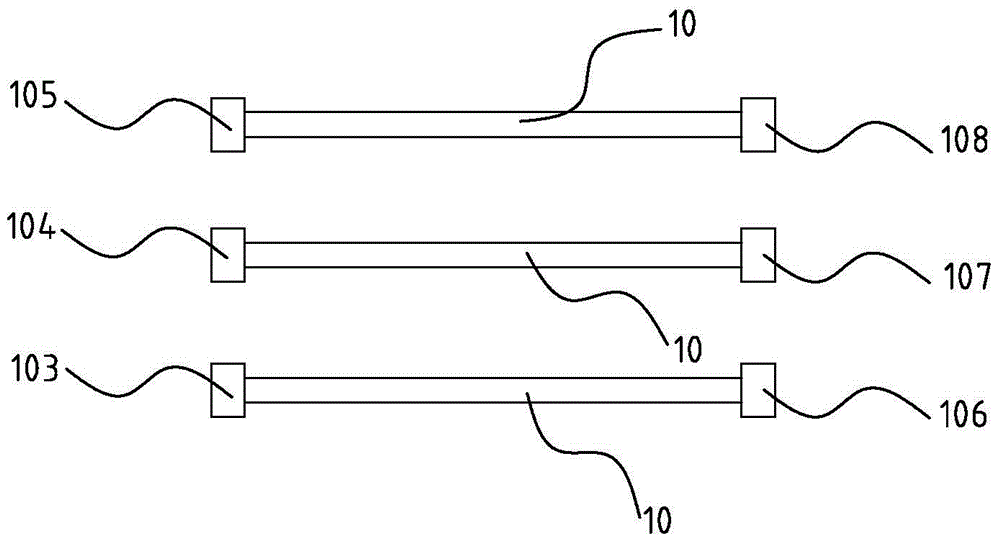

[0030] Please refer to Figure 6 , Figure 7 , Figure 6 Shown as a schematic structural view of a preferred embodiment of the coaxial path testing device of the base of the present invention, Figure 7 It is a schematic diagram of the circuit structure of a preferred embodiment of the coaxial path testing device of the base of the present invention, Figure 8 It is a schematic diagram of the structure of the shorting joint of a preferred embodiment of the coaxial path testing device of the base of the present invention.

[0031] In order to achieve the above object, the present invention provides a coaxial path testing device for the base, the base 100 (please refer to figure 1 , figure 2 , may include a base plate 101 and a back plate 102) having first coaxial interfaces 103, 104, 105 connected to the coaxial interface of the electronic product and connecting with the first coaxial interfaces 103, 104, 105 through the coaxial line 10 (please refer to the image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com