Cholesteric liquid crystal and reflective-type circular polarization sheet thereof, and manufacturing method

A cholesteric liquid crystal, circular polarizer technology, applied in chemical instruments and methods, liquid crystal materials, polarizing elements, etc., can solve problems such as difficulty in large-scale production, and achieve widened reflection bandwidth, good thermo-mechanical stability, and widened options. The effect of reflection bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the present invention will be further explained through specific embodiments in conjunction with the drawings.

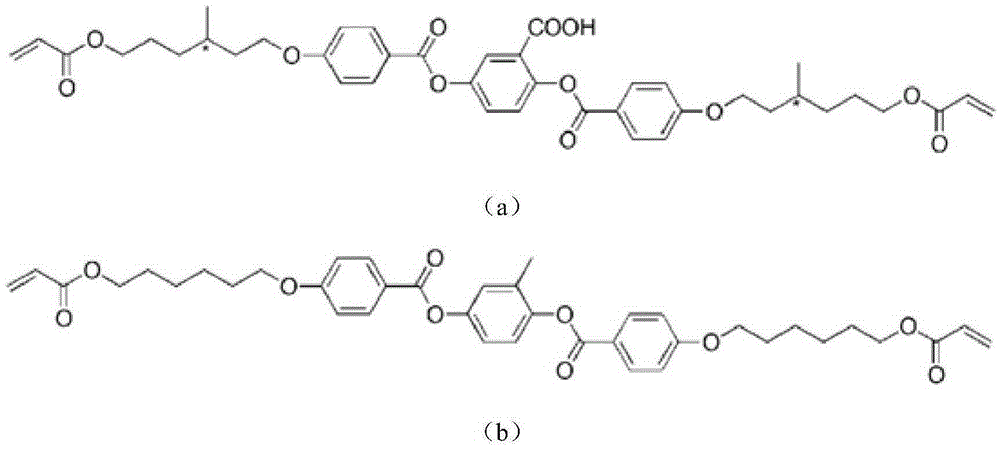

[0041] Such as figure 1 As shown, the preparation method of the reflective circular polarizer based on cholesteric liquid crystal of this embodiment includes the following steps:

[0042] 1) Provide base material of polymer materials:

[0043] The substrate adopts a biaxially stretched polyethylene terephthalate film with a thickness of 20 μm.

[0044] 2) Using wire rod coating method to coat the guide layer on the substrate as a hydrogen bond donor:

[0045] Dilute the 50% polyethyleneimine PEI aqueous solution to 5%, coat it on the substrate with a wire rod with a wet film thickness of 6μm on a wire rod coater, and bake it in an oven at 70°C for 5 minutes. The water is removed to obtain a guide layer with a thickness of about 1 μm, which serves as a hydrogen bond donor.

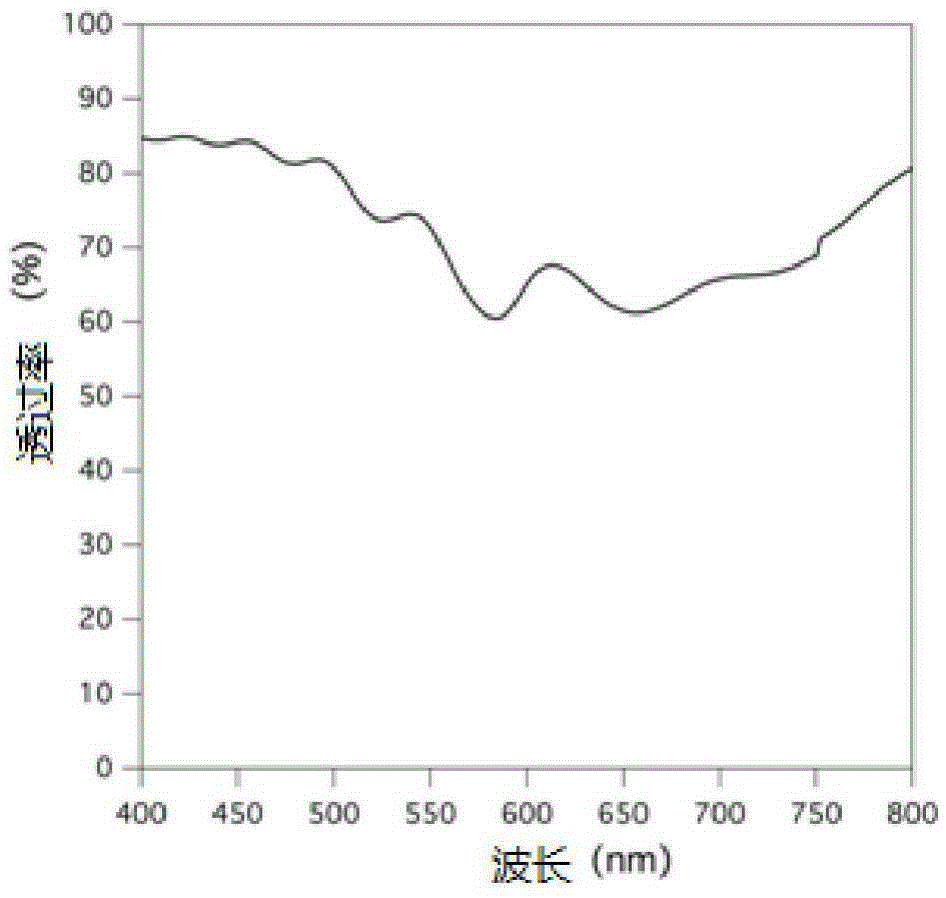

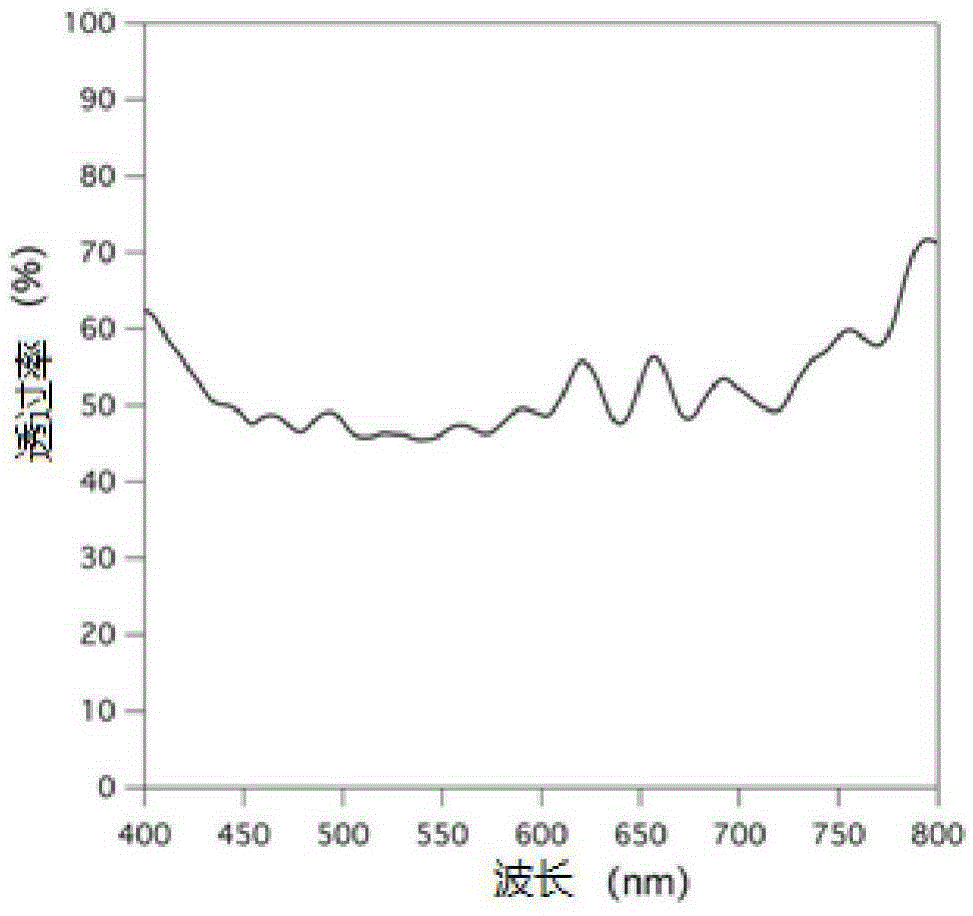

[0046] 3) Coating cholesteric liquid crystal on the guiding layer as a hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com