Back surface mounting type airflow sensor and welding structure

A technology of airflow sensor and welding structure, which is applied in the direction of electrical connection of printed components, instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Next, the technical solutions in the embodiments of the present invention will be described in conjunction with the present invention, which is clearly, and it is intended to be described herein, not all of the embodiments of the present invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

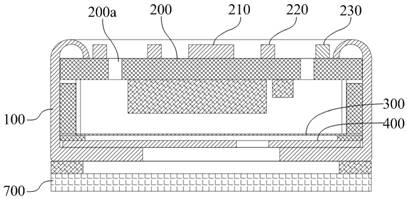

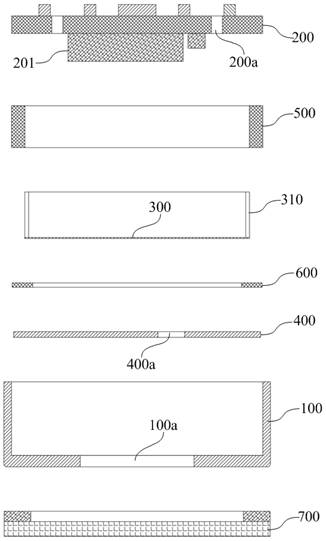

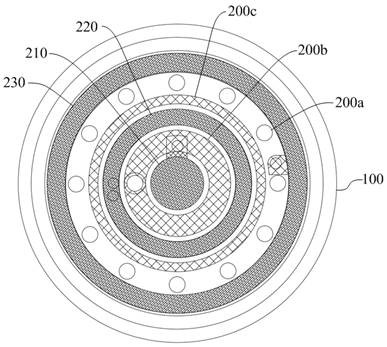

[0026]Please refer to the instructionsFigure 1-3In the embodiment of the present invention, a back surface mount type gas flow sensor is proposed, and the housing 100 of the back surface mount type gas flow sensor is opened, and the package body formed by the PCB plate 200, and the bottom wall of the outer casing 100 is provided with the package communication. The first air hole 100a, the PCB plate 200 is provided with a second pore 200a in communication with the package, and a diaphragm 300 and a pole piece 400 disposed up and do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com