A structurally improved industrial camera housing

A technology for industrial cameras and casings, which is applied to cameras, camera bodies, optics, etc., can solve problems such as heat generation and reduced camera service life, and achieve the effects of reducing the impact of life and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

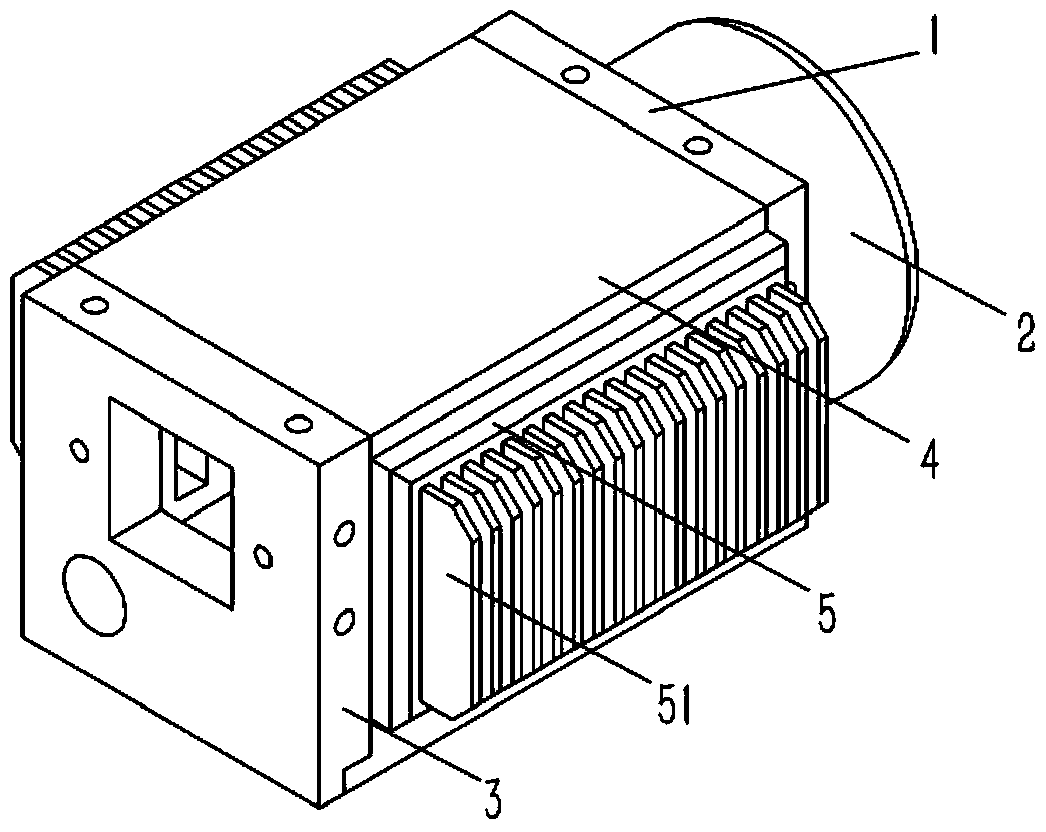

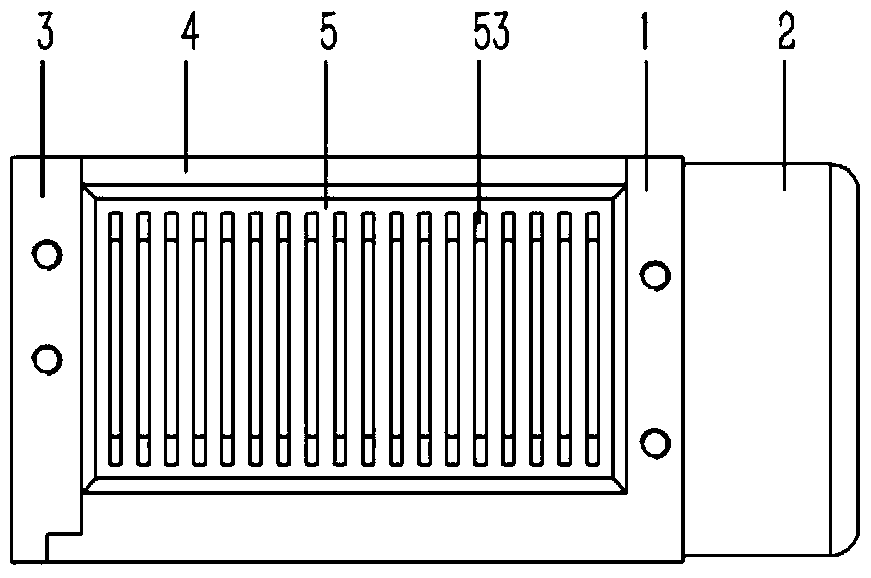

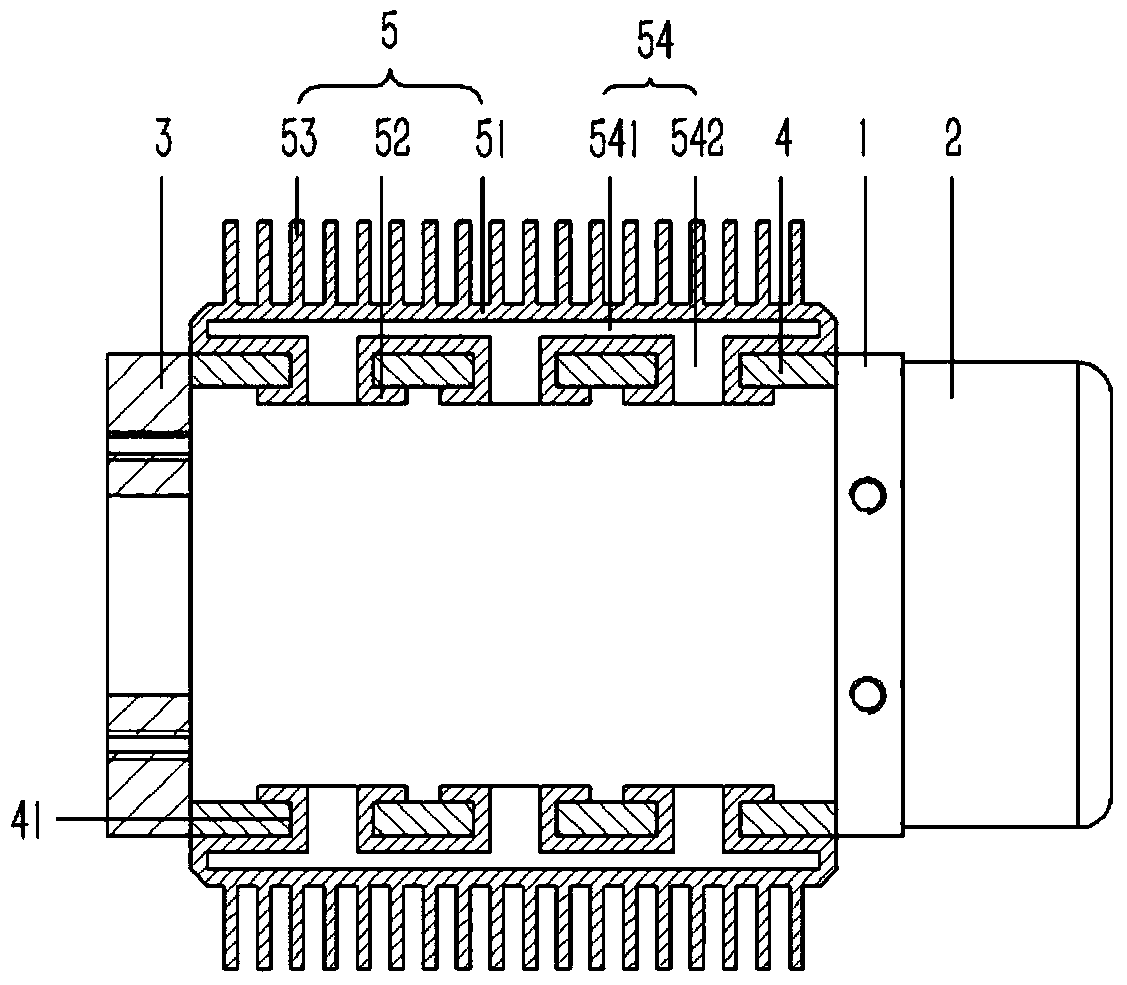

[0013] Example: see figure 1 , 2 . As shown in 3, an industrial camera housing with improved structure includes an L-shaped mounting base 1, a lens protection shell 2 is fixed on the front end surface of the mounting base 1, and a rear cover plate 3 is fixed on the rear end surface of the mounting base 1 , the mounting seat 1 between the rear cover 3 and the lens protection shell 2 is fixed with a 'X'-shaped case 4, and the side wall of the case 4 is provided with a heat sink 5, the heat sink 5 includes a side plate 51, the side plate There are several T-shaped plug joints 52 formed on the inner end surface of 51, the inner end surface of the side plate 51 is against the side wall of the casing 4, and a plurality of heat dissipation plates 53 are formed on the outer end surface of the side plate 51; the casing There are several vertical slots 41 formed on the side wall of 4, and the plug connector 52 is plugged into the slot 41 of the casing 4; heat dissipation grooves 54 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com