A kind of electrical packaging method of optoelectronic device

A technology of optoelectronic devices and packaging methods, which is applied in the field of optical communications, can solve the problems of reduced tolerance and difficulty in adding more PIN needles, and achieve the effects of reducing assembly difficulty, improving efficiency and reliability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

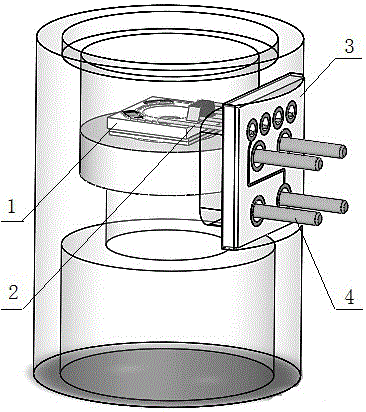

[0027] Embodiment 1 takes a tunable optical receiving sub-module as an example to further describe the electrical packaging method of the optoelectronic device.

[0028] Such as image 3 As shown, a photoelectric device electrical packaging method, the optical device includes a housing, internal devices, the internal device includes an adjustable filter, a heating resistor 1 is attached to the adjustable filter; a plug is welded on the heating resistor 1 Needle or lead wire 2, ceramic substrate 3 is set on the side of the housing, the internal device is packaged by the combination of the housing and ceramic substrate 3, the ceramic substrate 3 is connected to the electrode of the internal device through the pin or lead wire 2, and the external pin is drawn out at the same time 4. The pins or leads 2 are fixed by welding or glue outside the package casing.

[0029] The pin or wire solution in this embodiment can be welded or glued outside the package shell, replacing the tradi...

Embodiment 2

[0033] Embodiment 2: as Figure 9 , Figure 10 Shown, the inventive method can also be used for photoelectric pulse tester, optical counter, comprise the photodiode with photoelectric switch; Or polarization detector, comprise full polarization state power detector, optical channel polarization state detector; Adjustable filter Partial replacement with switches or adjustable attenuators; any combination of adjustable filters, switches and adjustable attenuators, or a combination of all three; for specific two-port devices, electrical adjustment components, such as switches and attenuators, need to be added in the middle , Adjustable filter.

[0034] Figure 9 , Figure 10 Among them, 10-optical interface or mirror; 11-photoelectric switch, or electric adjustment components, such as micro-electromechanical switches, heating resistors, electric drive components, electro-optical modulators, etc., or electro-rotating polarizers, or shutter MEMS chips; 12 - Photodiode and elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com