A kind of pulp drying equipment and its control method

A technology of drying equipment and a control method, which is applied in the field of papermaking, can solve problems such as long time consumption, and achieve the effects of avoiding violent fluctuations, uniform heating process, and realizing the change of action angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

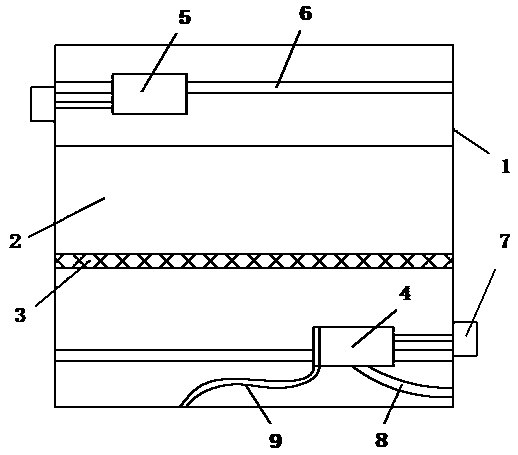

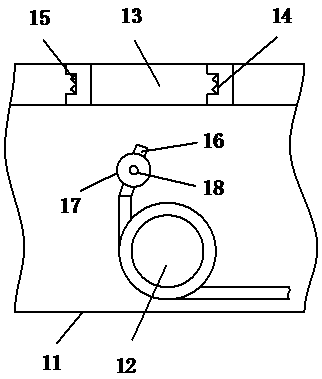

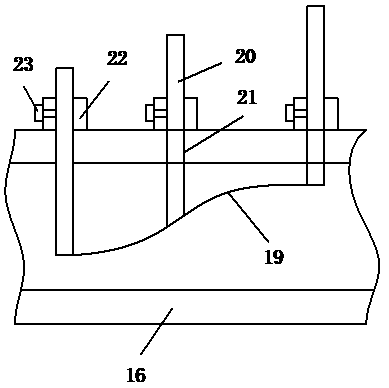

[0031] refer to Figure 1-6 A specific embodiment of the present invention includes a box body 1, a drying tray 2 is fixed inside the box body 1, the bottom surface of the drying tray 2 is a filter screen layer 3, and a first heater 4 is arranged below the filter screen layer 3 , the top of the filter layer 3 is provided with a second heater 5, the first heater 4 and the second heater 5 are slidably installed on the slide bar 6, and the first heater 4 and the second heater 5 pass through the cylinder respectively 7 realizes sliding on the slide bar 6; the first heater 4 is provided with an air supply pipe 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com