Tool for machine-cutting a workpiece

A technology of cutting and tooling, which is applied in the field of tools for cutting workpieces, can solve problems such as damage, insufficient removal of chips, and reduced service life of tools, and achieve easy work, high load capacity, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

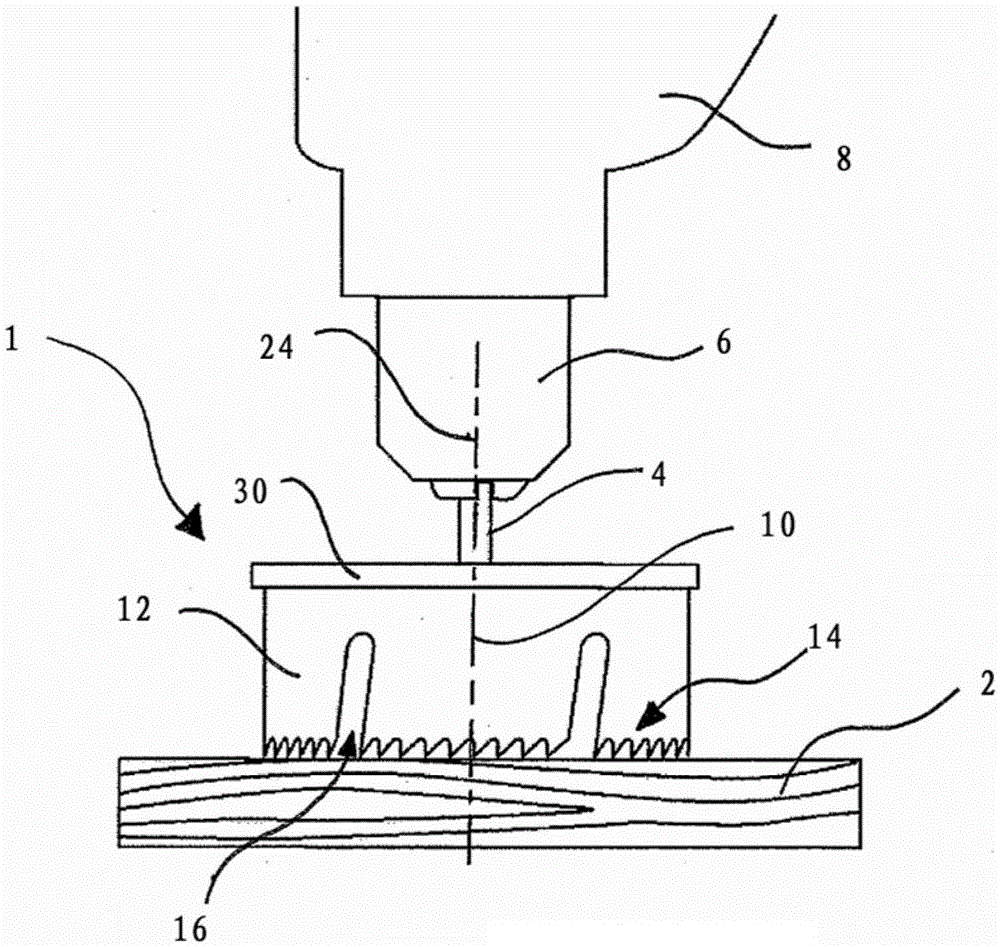

[0027] According to figure 1 In the exemplary embodiment shown, the tool 1 is clamped in the rotationally driven tool spindle 6 of the machine tool 8 , so that the non-positive and / or The form-fitting connection makes it possible to transmit the rotational movement of the tool spindle 6 to the tool 1 .

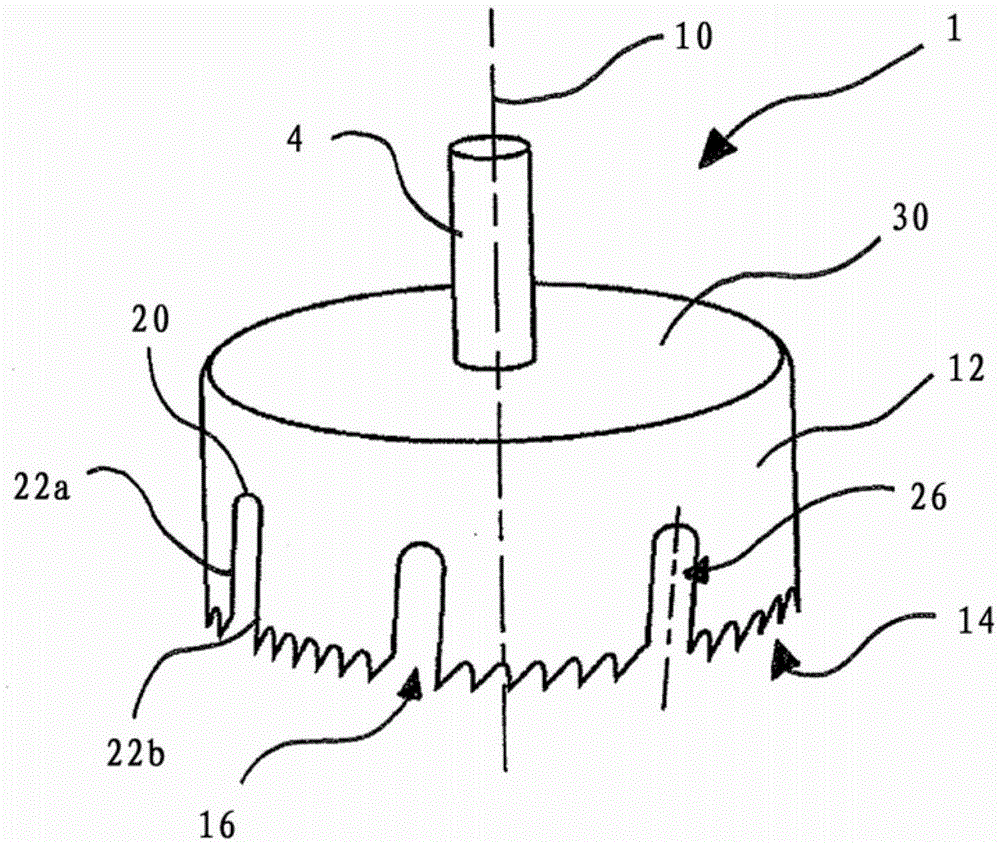

[0028] In this case, the tool center axis 10 coincides with the axis of rotation 24 of the rotationally driven tool spindle 6 . The fastening means 4 is also connected to a carrier element 30 , into which the tool housing is in turn locked in a rotationally fixed manner at least in the direction of rotation.

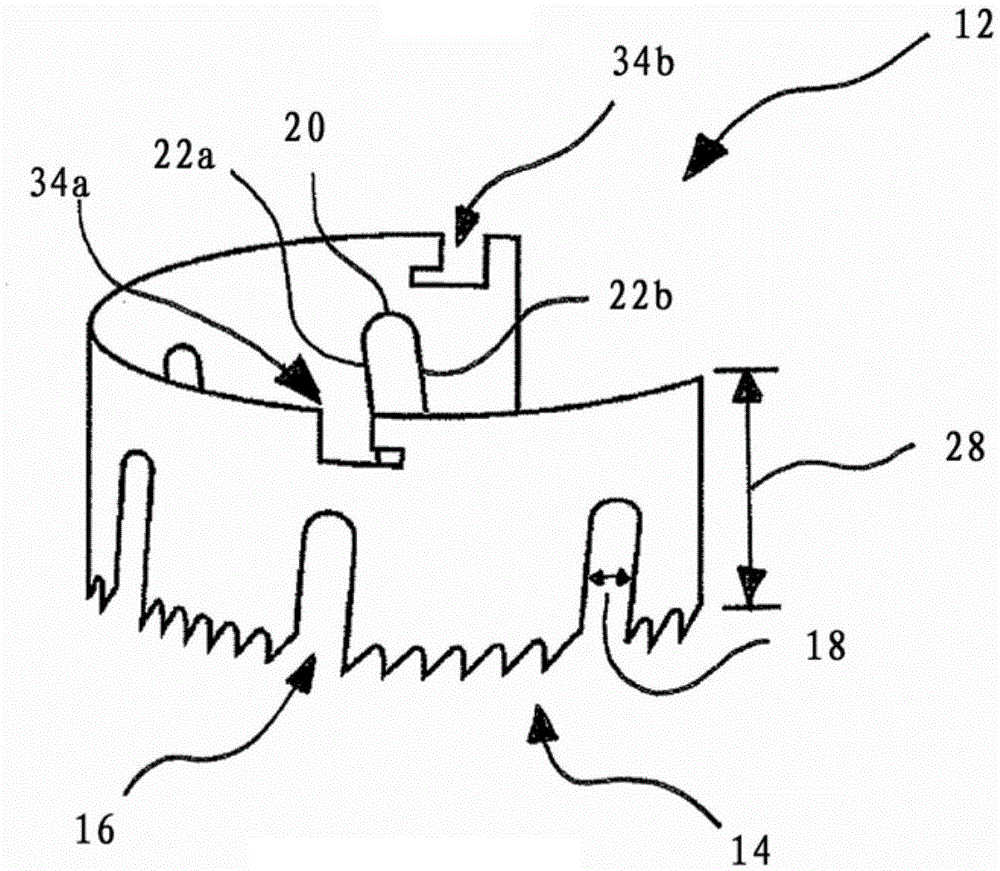

[0029] A toothing 14 is provided on the side of the tool housing 12 facing away from the support element 30 and the fastening means 4 . The toothing 14 and the tool housing 12 have a recess 16 which extends from the toothing 14 up to more than half the height of the tool housing.

[0030] The toothing 14 interrupted by the recess 16 is in contact with the workpiece 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com