Scribing fine adjustment device and scribing method using the same

A technology of fine adjustment and leveling mechanism, which is applied in the field of angle adjustment device and marking and height, which can solve the problem of inaccurate control of height or angle adjustment range, affecting the accuracy and efficacy of marking process, and large process connection error and other problems, to achieve the effect of improving marking efficiency, wide application range, and low requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

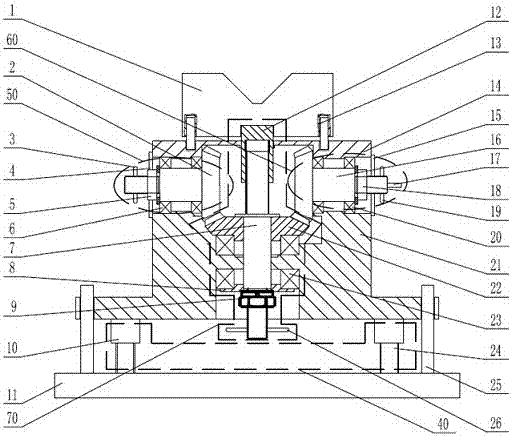

[0046] The scribing fine adjustment device of the present invention is suitable for scribing of box-like parts. When using the scribing fine-adjustment device to scribble box-like parts, it only needs to adjust the angle of the image displayed by the laser positioner 17. That is, without being affected by changes in parameters such as height, the specific working process is as follows:

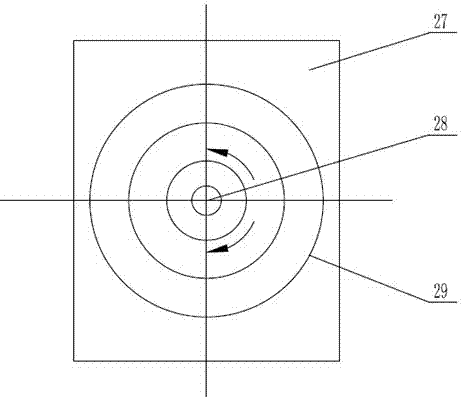

[0047] First, the box-like parts 27 that need to be marked are placed on the horizontal plane to be marked.

[0048] Next, place the marking line fine adjustment device in the present invention on a horizontal plane to make it stable, rotate the supporting joints 10 respectively, adjust their heights and make them be on the same horizontal plane, so that the marking line fine adjustment device can be adjusted flat; as attached figure 2 As shown, adjust the position of the scribing fine-tuning device so that the light source of the laser positioner 17 is aimed at the surface of the box-like p...

Embodiment 2

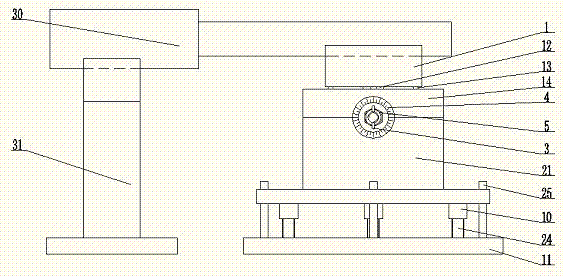

[0052] The scribing fine adjustment device of the present invention is not only suitable for scribing of box parts, but also suitable for scribing of shaft parts. When using the scribing fine adjustment device to scribing shaft parts, only the height needs to be adjusted. It no longer uses the laser locator, so it will not be disturbed by angle factors. Its specific working process is as follows, as attached image 3 Shown:

[0053] First, put the scribe line fine-adjustment device and its matching fixed V-shaped block 31 on a plane, and rotate the support joint 10 upwards to adjust their heights so that they are on the same level, so that the scribe line The fine adjustment device is leveled and the V-shaped block 1 is improved, and then the two ends of the shaft parts 30 are respectively placed on the second V-shaped block of the fixed V-shaped block 31 and the V-shaped block 1 of the multifunctional marking device.

[0054] Then, by adjusting the coarse adjustment handle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com