High-temperature-resisting carbon fiber bicycle rim

A carbon fiber and bicycle technology, applied in the direction of wheels, spoke wheels, wheels made of non-metallic materials, etc., can solve the problems of loss of strength, fracture and deformation of the rim, and achieve a simple structure of the rim, ensuring safety and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

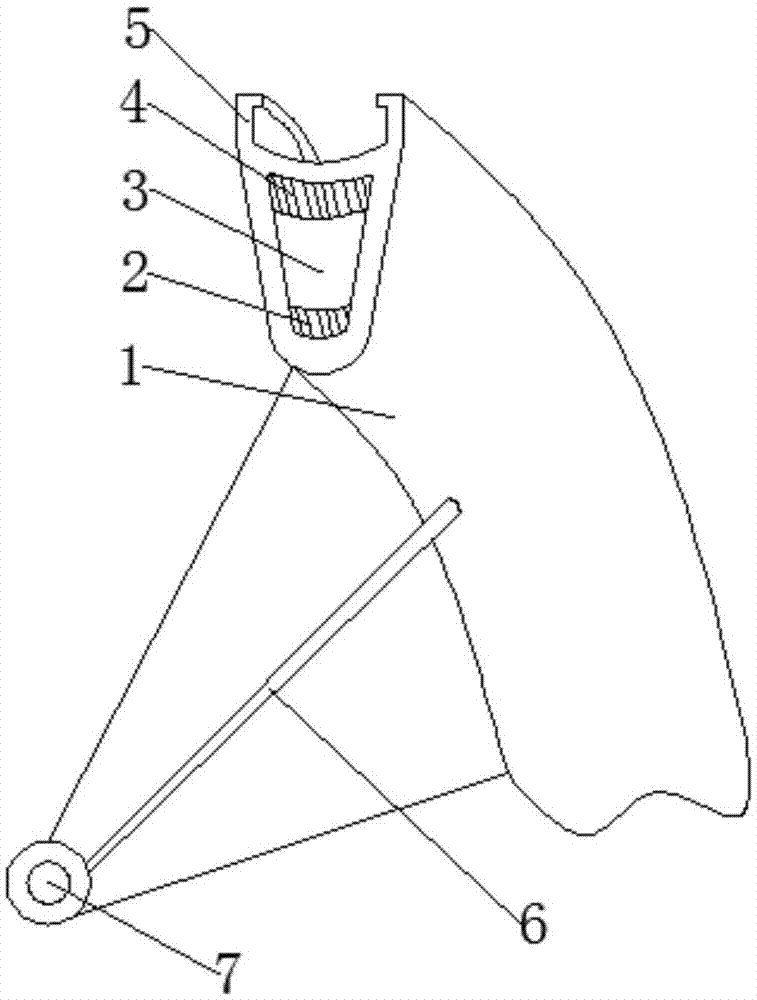

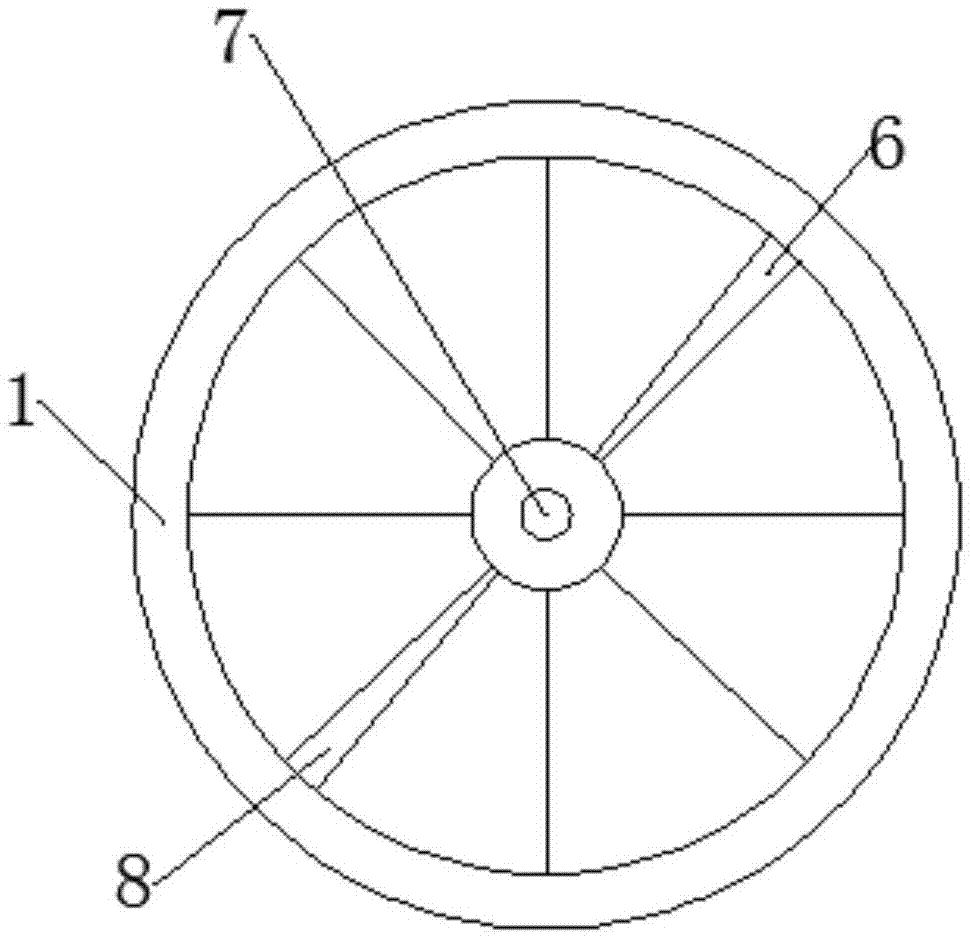

[0016] In addition, a high-temperature-resistant carbon fiber bicycle rim mentioned in the embodiment of the present invention includes a body 1, a lower buffer body 2, a cavity 3, an upper buffer body 4, a tire groove 5, an air intake pipe 6, an air cooling 7 and air outlet pipe 8, tire groove 5 is provided on the outside of the body 1, a cavity 3 is provided inside the body 1, an upper buffer body 4 is provided at the upper end of the cavity 3, and a lower buffer body 2 is provided at the lower end of the cavity 3 , the inside of the body 1 is provided with a point connected to one end of the intake pipe 6, and the other end of the intake pipe 6 is connected to the air cooler 7, and the air cooler 7 is fixed on the hub of the rim, and connected to the intake pipe 6. An air outlet pipe 8 is arranged at a sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com