Multi-hoist-point single-layer winding winch with deflecting pulley

A technology of diverting pulleys and multiple lifting points, applied in the direction of hoisting device, mainspring mechanism, etc., can solve the problems of increased wear and tear of wire ropes, slipping grooves, and no overpasses are allowed, achieving small size, simple structure, and preventing disordered ropes. the dangerous effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

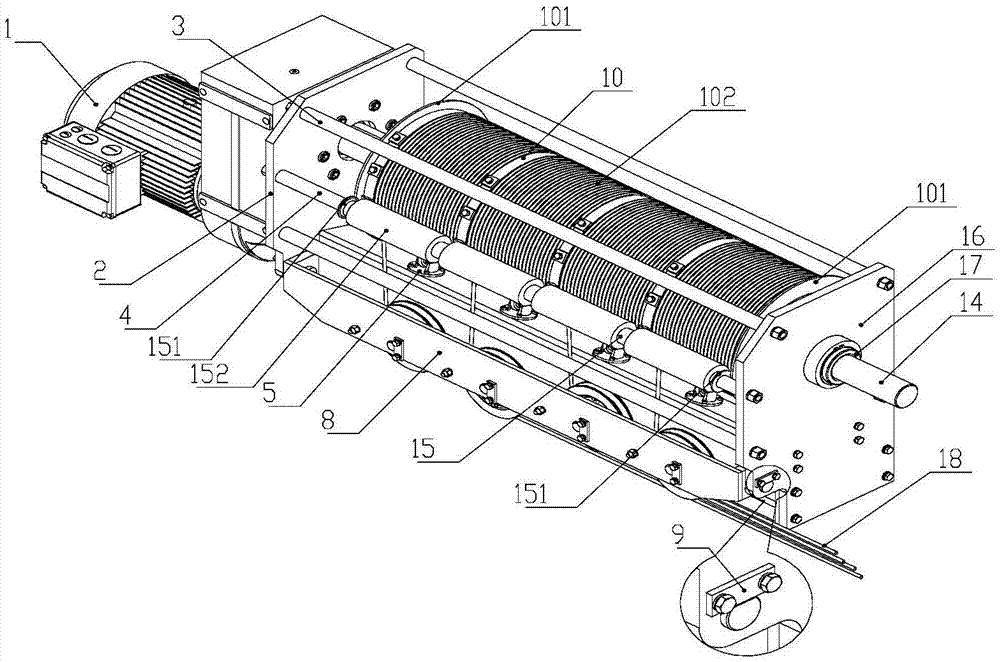

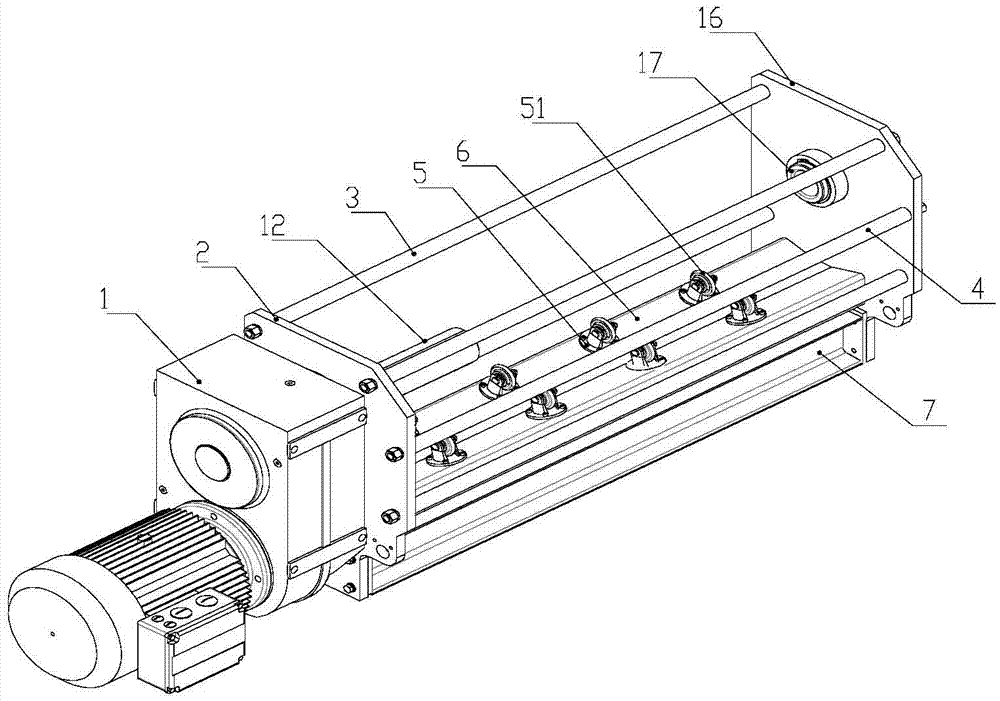

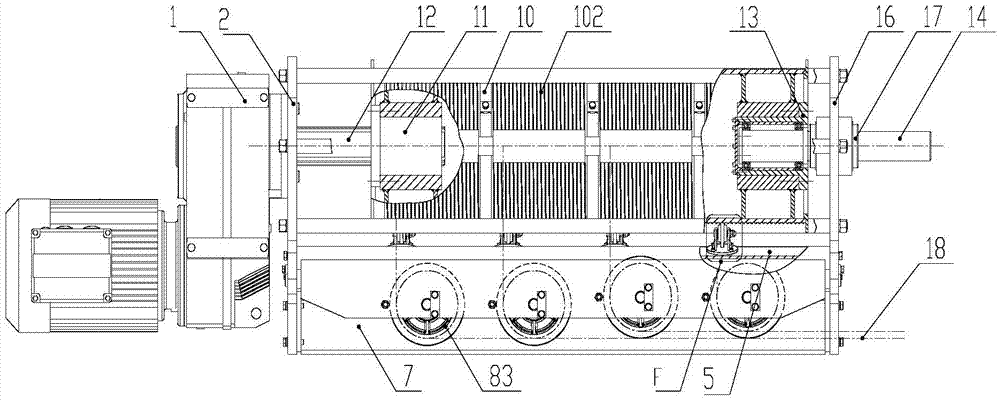

[0030] Such as figure 1 , figure 2 As shown, the present invention includes a bracket assembly, a geared motor 1, a linear bearing sleeve 17, a reel 10 and a plurality of steel wire ropes 18, and the bracket assembly includes a left side panel 2, a right side panel 16, a base 7 and is installed on the left side panel 2 and The four distance rods 3 between the four corners of the right side board 16, the left side board 2 and the right side board 16 are positioned and fixed in parallel with the four distance rods 3 distributed at the four corners of the two side boards, and the reel 10 is arranged on the bracket Between the left side plate 2 and the right side plate 16 of the assembly, the base 7 is installed between the left side plate 2 and the lower part of the right side plate 16 under the reel 10, and the reduction motor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com