High-impact-resistant low-temperature-resistant stress-cracking-resistant regenerated ABS material

An ABS material and anti-stress cracking technology, which is applied in the stress-cracking-resistant recycled ABS material and its preparation, low temperature resistance, and high impact fields, can solve the problems of low mechanical properties, and achieve the effect of improving impact resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

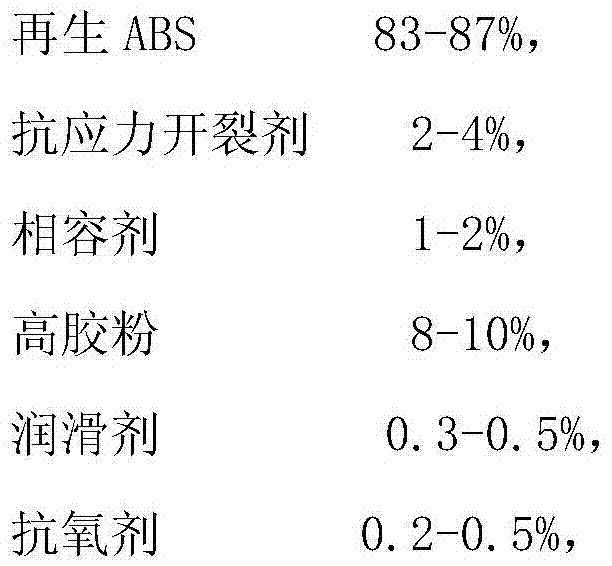

[0023] A high impact, low temperature resistant, stress crack resistant recycled ABS material comprising the following components by weight ratio:

[0024]

[0025] The preparation method of the above-mentioned high-impact, low-temperature-resistant, and stress-crack-resistant modified regenerated ABS material comprises the following steps:

[0026] (1) Dry the regenerated ABS at 85°C for 4 hours;

[0027] (2) Metallocene LLDPE, calcium stearate, antioxidant 1010 and antioxidant 168 are added to a high-speed mixer and mixed uniformly to obtain compound I;

[0028] (3) Add regenerated ABS, POE-MAH, and high rubber powder processed through step (1) into the mixture I and mix evenly, discharging;

[0029] (4) putting the mixture obtained in step (3) into a twin-screw extruder for melting, kneading, extruding, cooling, pelletizing, and packaging to obtain the product;

[0030] The extrusion process is as follows: the speed of the main engine is 35Hz, the feeding frequency is ...

Embodiment 2

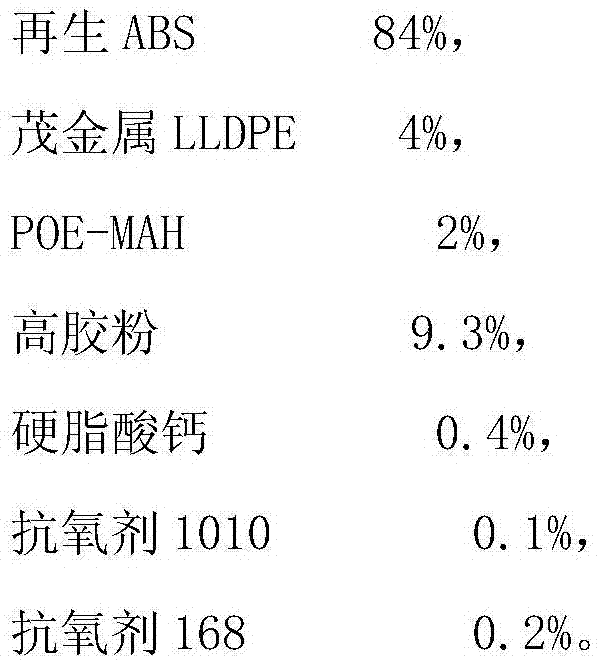

[0032] A high impact, low temperature resistant, stress crack resistant recycled ABS material comprising the following components by weight ratio:

[0033]

[0034] The preparation method of the above-mentioned regenerated ABS material is the same as in Example 1.

Embodiment 3

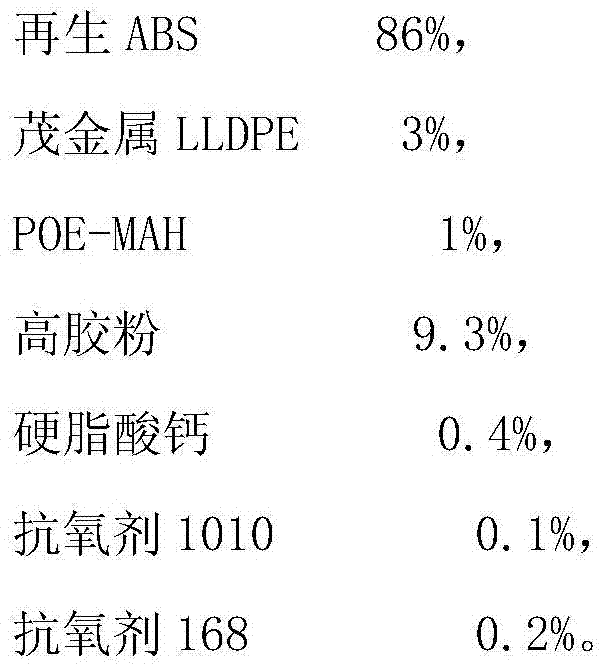

[0036] A high impact, low temperature resistant, stress crack resistant recycled ABS material comprising the following components by weight ratio:

[0037]

[0038] The preparation method of the above-mentioned regenerated ABS material is the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap