A kind of oblique angle tongue-and-groove building formwork

A construction formwork and groove-and-groove technology, which is applied in the field of oblique angle-and-groove construction formwork, can solve the problems of high connection strength, fast connection speed, and limited installation space of building formwork, achieving high connection strength, improving construction efficiency, and stress strength balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

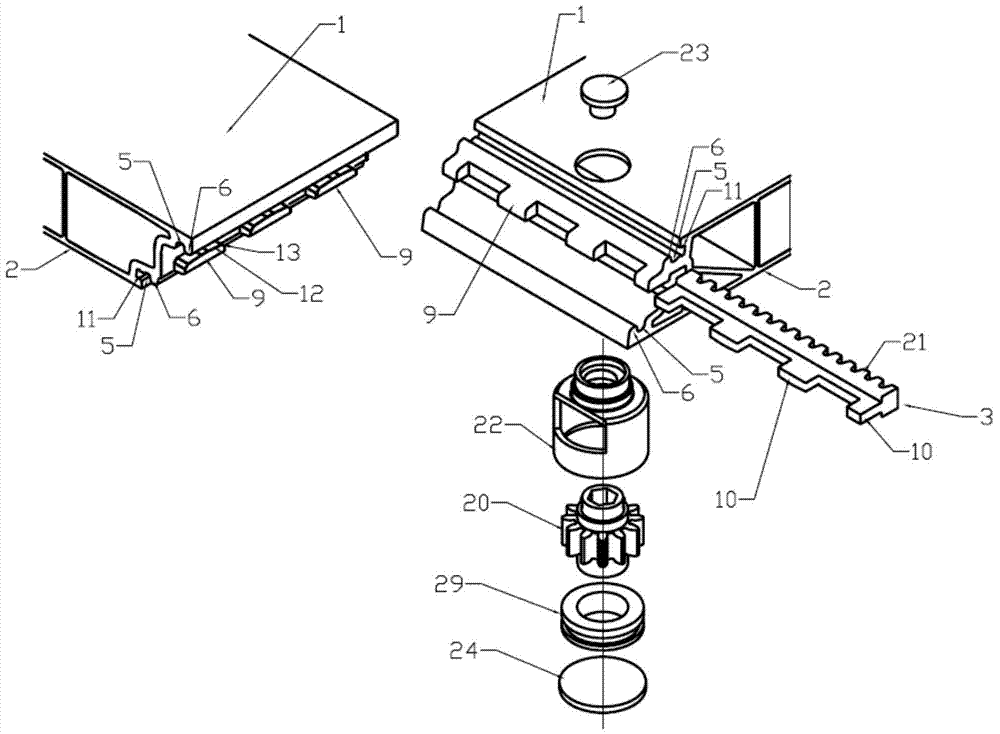

[0057] Such as Figure 1-5 As shown, a beveled tongue and groove building formwork of this embodiment has

[0058] A pouring surface 1 and an outer surface 2 opposite to the pouring surface 1;

[0059] A groove-and-groove structure, formed on the connecting edge between the pouring surface 1 and the outer surface 2, the groove-and-groove structure includes a fitting structure, and the fitting structure is suitable for combining with the edge and the two sides The pouring surface 1 of one of the building formwork forms an included angle, and the movement in the direction of embedding movement is embedded with the adjacent building formwork. and separation in the direction of the embedding movement direction; and

[0060] The locking structure includes a locking piece 3 that is movably and immovably arranged on the edge in the direction of embedding movement, and a locking surface 4 that is set on the corresponding edge of the adjacent template. The locking piece 3 is molded o...

Embodiment 2

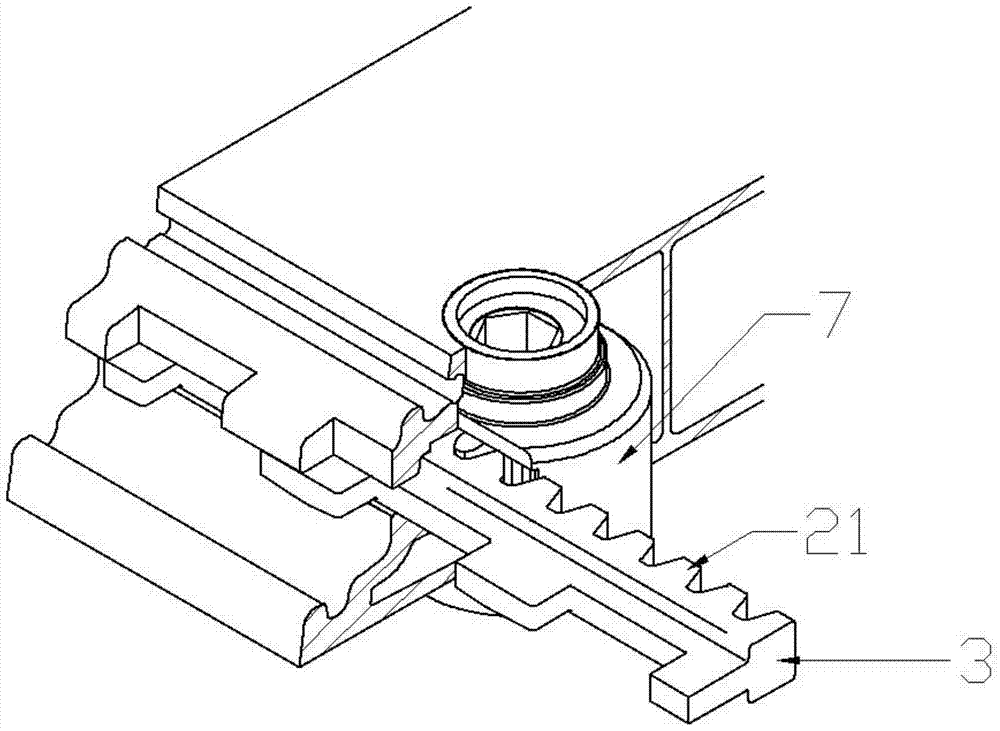

[0072] Such as Figure 6 and 7 As shown, the difference between this embodiment 2 and embodiment 1 lies in the formation of the locking surface 4, the shape of the slot, and the structure of the locking member 3. In this embodiment 2, the locking surface 4 is formed on the corresponding Adjacent to the groove on the edge of the building formwork, the locking member 3 is composed of the split locking part 10 and the driving part 14, and at least one transmission structure arranged between the locking part 10 and the driving part 14 The driving mechanism 7 drives the driving part 14 to slide along the direction of the edge extension, the driving structure drives the locking part 10 to extend into or withdraw from the locking surface 4, and the shape of the slot is suitable for Keep the driving part 14 fixed to slide along the edge extending direction, and the locking part 10 moves to the locking direction of the locking surface 4 on the adjacent building formwork.

[0073] In ...

Embodiment 3

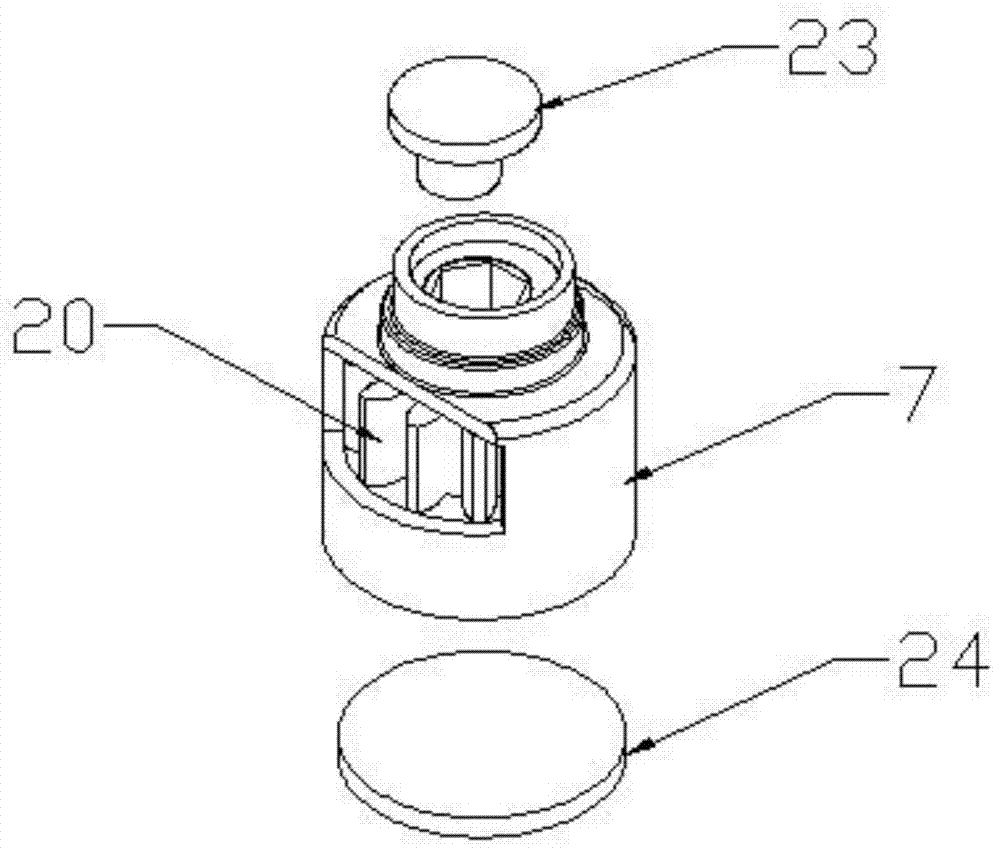

[0076] Such as Figure 8 As shown, the difference between this embodiment 3 and embodiment 1 is that the locking surface 4 is a groove formed on the edge of the adjacent building formwork, and the driving mechanism 7 drives the locking member 3 to extend along the edge direction while moving towards the locking surface 4 of the adjacent building formwork, a guide structure is also provided between the locking piece 3 and the building formwork where the locking piece 3 is located, and the guiding structure is opposite to the locking piece 3 The guide is moved in the direction of said locking face 4 of the adjacent building formwork. The toggle member is a gear 20, the rotating shaft of the gear 20 is arranged perpendicular to the edge; the toggled structure is a fan-shaped rack 30 formed on the locking member 3; the guide structure includes a molded The second guide groove 17 on the locking member 3, and one end is connected on the building template, and the other end passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com