Energized Elastic Seat Structure and Double Eccentric Butterfly Valve Using It

An elastic sealing and valve seat technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of sealing surface leakage gap, high production cost, low leakage level requirements, etc., to achieve effective sealing and avoid stuck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

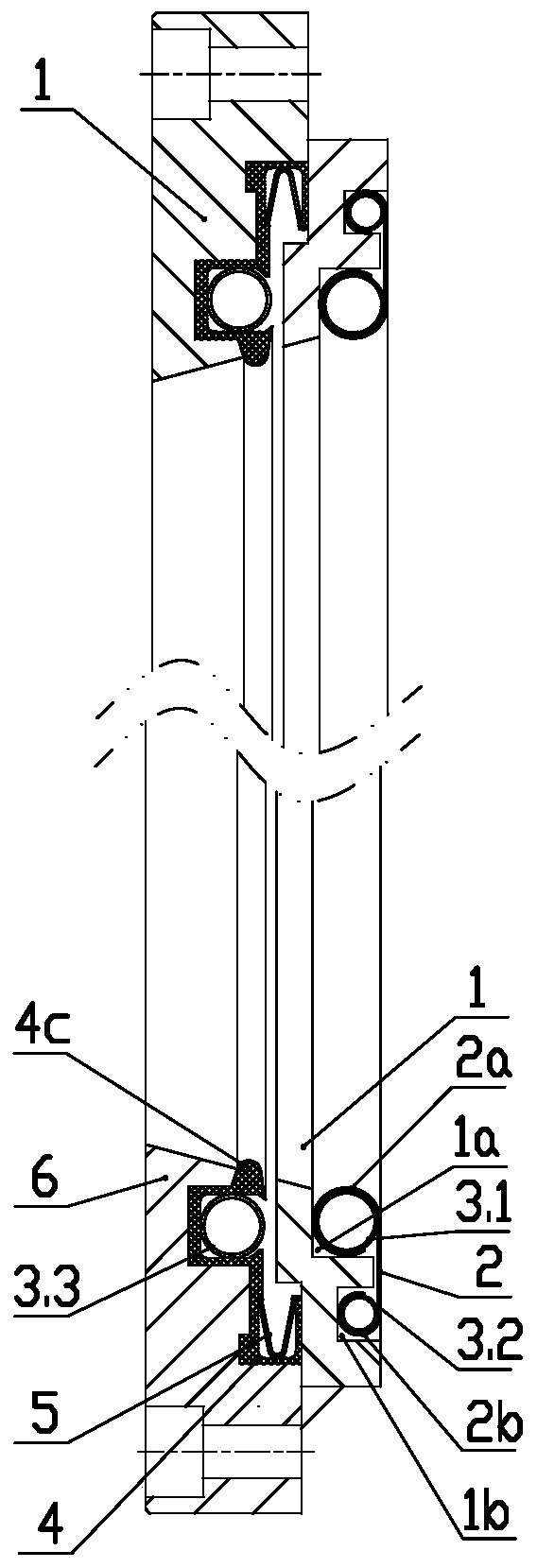

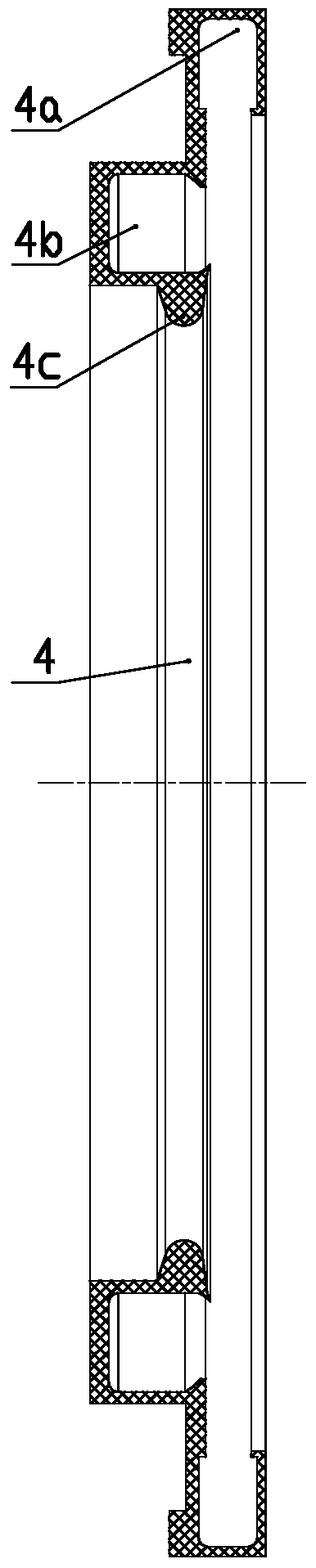

[0025] Such as Figure 1~Figure 4 As shown, embodiment 1 is an energy-enhancing elastic sealing valve seat structure, which mainly consists of valve seat 1, metal sealing ring 2, first coil spring 3.1, second coil spring 3.2, third coil spring 3.3, non-metallic It is composed of elastic sealing ring 4, V-shaped spring 5 and pressing ring 6, etc.

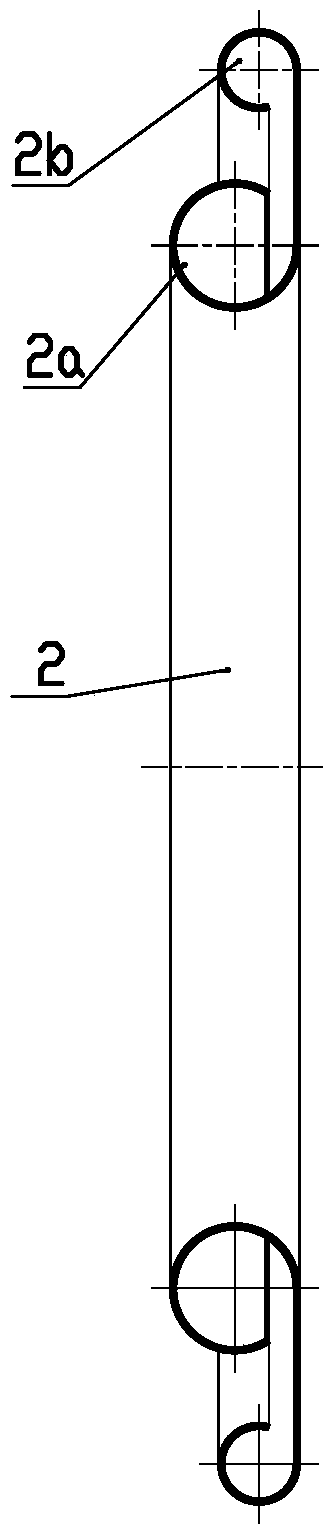

[0026] Such as figure 1 As shown, in this embodiment 1, the metal sealing ring 2 is arranged inside the valve seat 1, the metal sealing ring 2 is circular, and the inner and outer edges of the metal sealing ring 2 are respectively provided with inner peripheral C-rings 2a, The outer peripheral C-shaped ring 2b; the inner end surface of the valve seat 1 is provided with a concentric outer ring groove 1a and an inner ring groove 1b, and an annular step 1c is formed between the outer ring groove 1a and the inner ring groove 1b; the The inner peripheral C-ring 2a and the outer peripheral C-ring 2b of the metal sealing ring 2 are respec...

Embodiment 2

[0030] Such as Figure 4 , Figure 5 As shown, Embodiment 2 is a double eccentric butterfly valve, which mainly includes a valve body 7, a valve plate 8 and a valve stem 9. The valve plate 8 is fixedly mounted on the valve stem 9 and can be driven by the valve stem 9 to wind The rod 9 pivots, and the valve plate 8 cooperates with the valve seat structure installed in the inner cavity of the valve body 7 to control the opening and closing of the flow path of the butterfly valve; the valve seat structure adopts the energized elastic Sealing valve seat structure; the metal sealing ring 2, valve seat 1, non-metallic elastic sealing ring 4 and pressure ring 6 in the energy-enhancing elastic sealing valve seat structure are sequentially loaded into the inner cavity of the valve body 7, and the pressure ring 6 is passed through the screw Fastened on the valve body 7; the outer peripheral C-ring 2b of the metal sealing ring 2 is attached to the stepped surface of the valve body 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com