Air conditioner and refrigeratory system for LNG ship

A technology for LNG ships and freezers, which is applied in the field of LNG ship air conditioners and freezer systems, can solve problems such as increased installation costs, difficulties in power supply, and difficulties in oil replenishment, so as to reduce ship costs, improve energy utilization, and improve applicability and the effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

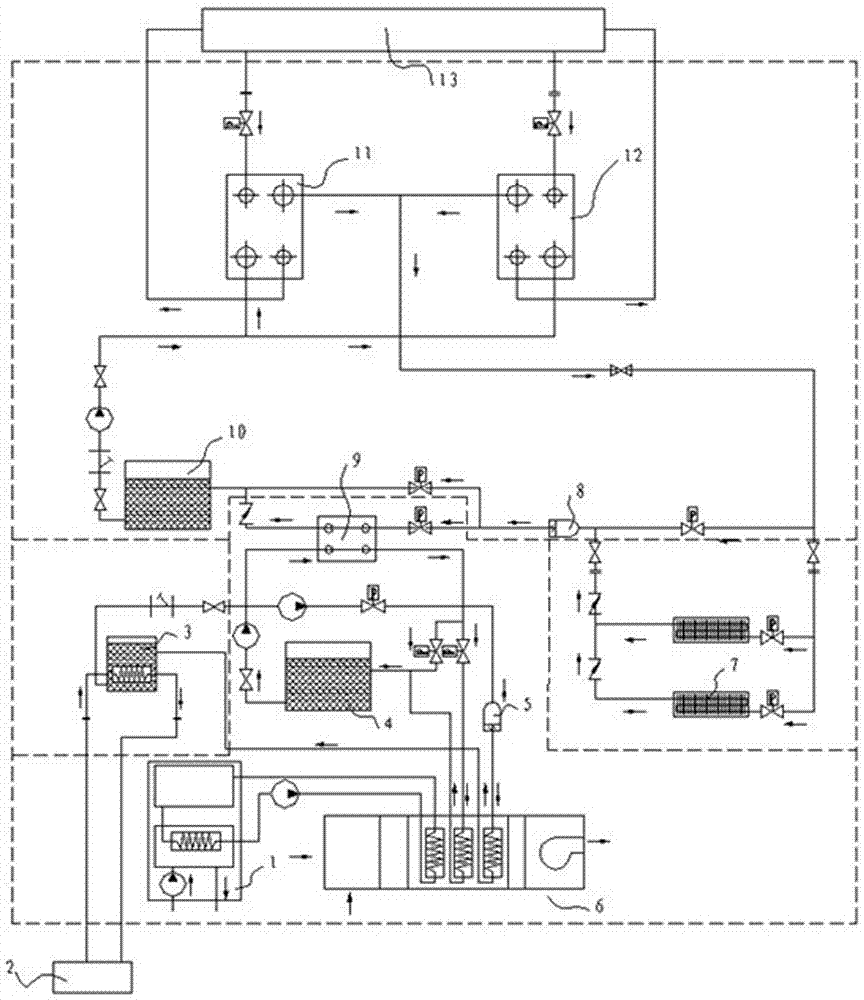

[0031] like figure 1 As shown, the LNG marine air conditioner and freezer system of the present invention includes a load-cooling module, an air-conditioning module, a freezer module, and a seawater heat exchange module 1, the cold energy input end of the load-load module is connected to the cold source body 13, and the freezer module The cold energy output terminal is successively connected to the freezer module and the air-conditioning module; the air-conditioning module includes a heating module, a cooling module, and an air supply module 6, the heating module is connected between the heat source body 2 and the air supply module 6, and the cooling module is connected to the load Between the cold module and the air supply module 6; the cold energy of the cold source body 13 enters the freezer module and the cooling module successively through the cooling module, and the cold supply module transfers the obtained cold energy to the air supply module 6 to cool the air, The ther...

specific Embodiment 2

[0041] The invention discloses an air conditioner of an LNG ship and a cold energy temperature control method of a freezer, comprising:

[0042] Primary cold energy cycle: LNG in the LNG gas supply system flows through the cold energy heat exchanger and releases cold energy. The electric heater 8, the first heat exchanger 9, and the second medium box 10 circulate, and the cold energy is released to the air at the freezer heat exchanger 7, and the cold energy is transferred to the air at the first heat exchanger 9. Secondary cold energy cycle;

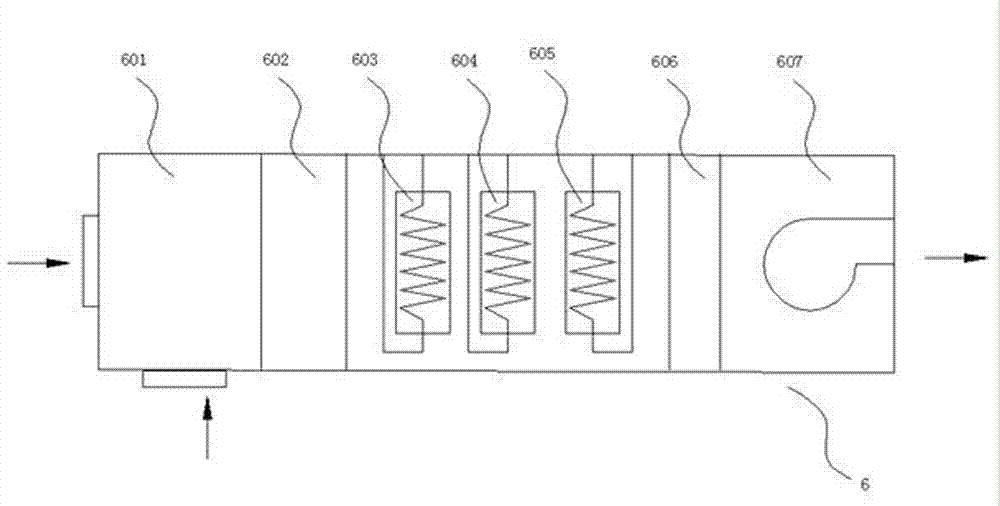

[0043] Secondary cold energy cycle: water glycol is used as the cold energy carrier to circulate between the first heat exchanger 9, the cold energy pipe 604, and the first medium box 4; The cold energy obtained in the cycle is transferred to the cold energy pipe 604 and transferred to the three-stage cold energy cycle at the cold energy pipe 604;

[0044] Three-stage cold energy cycle: use air as cold energy to circulate among the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com