Phase-change cold storage air-conditioning control room

A phase-change cold storage and computer room technology, which is applied in air conditioning systems, mechanical equipment, space heating and ventilation, etc., can solve the problems of ignoring the comprehensive energy efficiency of the computer room, long-term operation of the system with diseases, and no start-up strategy, etc., and achieves a significant effect of cold storage , Improve energy efficiency, improve the effect of environmental comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

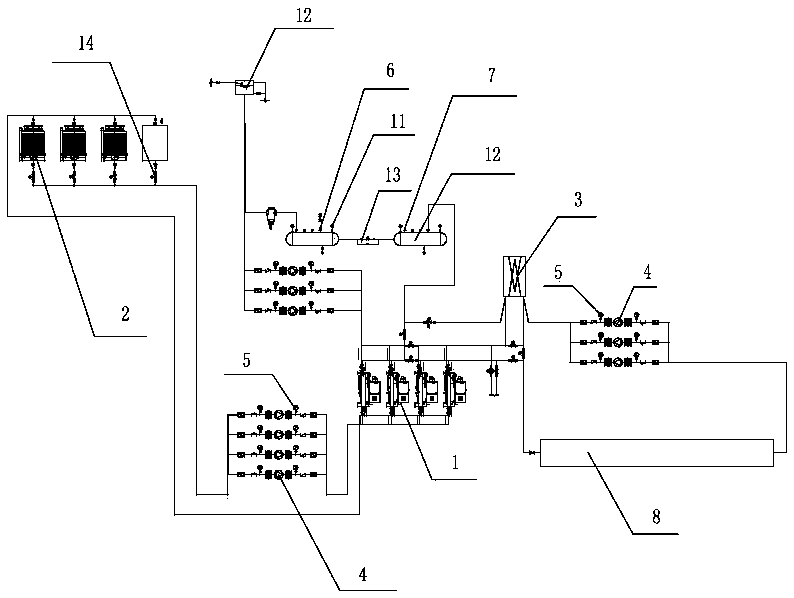

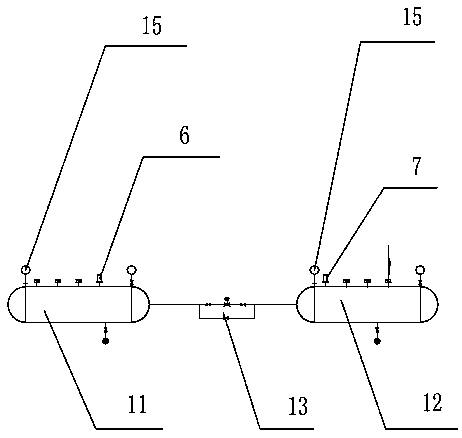

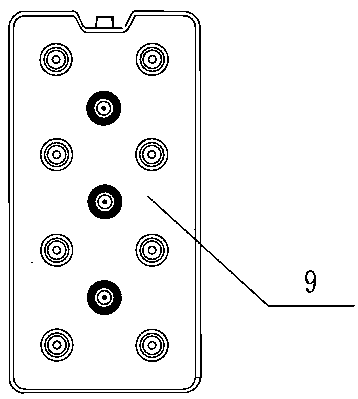

[0032] Embodiment 1, refer to attached figure 1 , attached figure 2 , attached image 3 :

[0033] A phase-change cold storage air conditioner room, including a refrigeration system composed of 4 refrigerators 1 connected in parallel, a heat exchange system 3 composed of 2 heat exchangers, a cooling system composed of 4 cooling water towers 2, and a cold storage system composed of 3 cold storage tanks 8 In the system, four one-way valves 4 and eight temperature sensors 5 are arranged between the refrigerator 1 and the cooling water tower 2, the temperature sensors 5 are located on both sides of the single valve 4, the refrigerator 1 and the cold storage tank 8 are connected in parallel to the heat exchanger, The heat exchanger is located in the machine room. The cold storage tank 8 and the cooling water tower 2 are connected in parallel to the refrigerator 1. Three check valves 4 and six temperature sensors 5 are arranged between the cold storage tank 8 and the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com