Energy-gathered cutting device for all-size gas blasting test of gas transmission steel pipe

A blasting test and cutting device technology, which is applied in blasting, blasting barrels, weapon accessories, etc., can solve the problems of not correctly reflecting the performance of crack arrest, and achieve the effects of high cutting efficiency, stable performance, and appropriate energy gathering angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] On October 27, 2014, the Conveyor Pipeline and Safety Evaluation Institute of the Institute of Pipeline Management and relevant units cooperated to successfully carry out a single-pipe full-scale gas blasting experiment of X90 longitudinal submerged arc welded steel pipe in Dongtai City, Jiangsu Province. This is the first full-scale gas blasting experiment of a large-diameter delivery steel pipe in China. The outer diameter of the test steel pipe is 1219mm, the length is 12m, and the wall thickness is 16.3mm. The test pressure is 12MPa, and the pressurized medium is air.

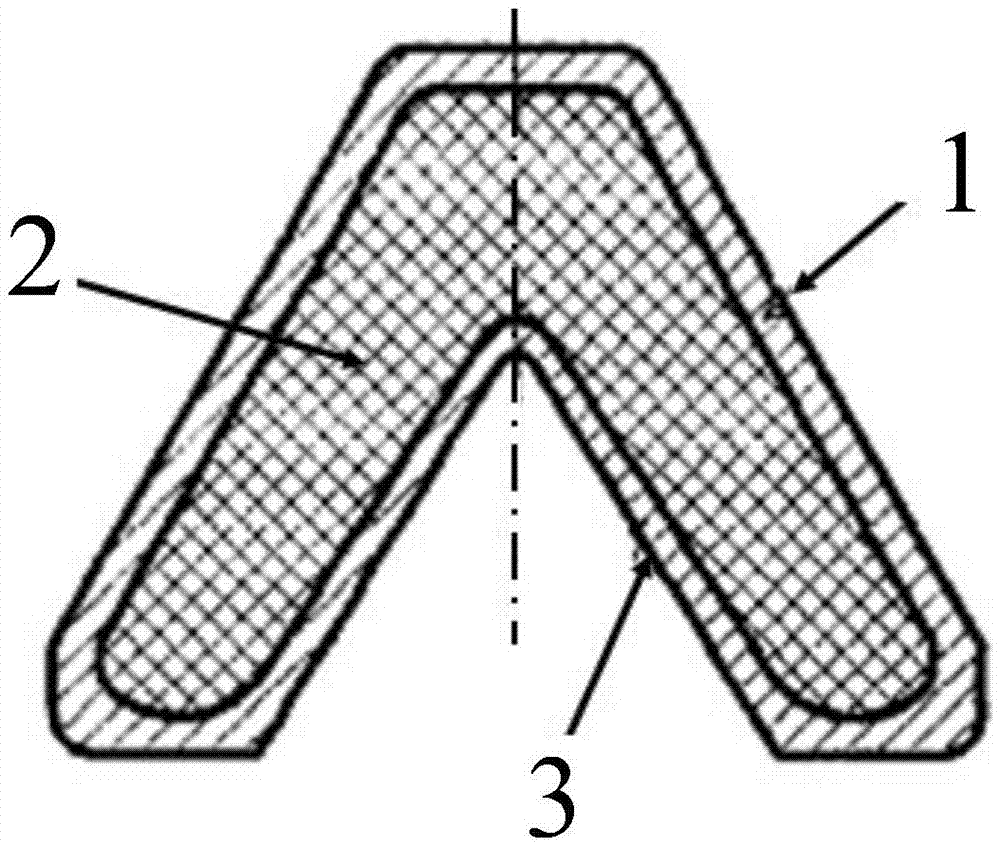

[0059] The full-scale gas blasting test is to place the linear energy-concentrating cutting device at the center above the steel pipe, and use a remote-controlled electric detonator to detonate. When in use, the linear energy-gathering cutting device of the present invention is placed on the crack-initiating steel pipe, and the electric detonator is placed in the middle above the linear energy-gathe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com