Warhead for rocket fire extinguishing bomb

A fire-extinguishing bomb and warhead technology, applied in the field of warheads, can solve the problems of potential launch safety hazards, poor coverage effect, plastic deformation and aging, etc., and achieve the effects of simple structure, increased dry powder loading, and low explosive power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

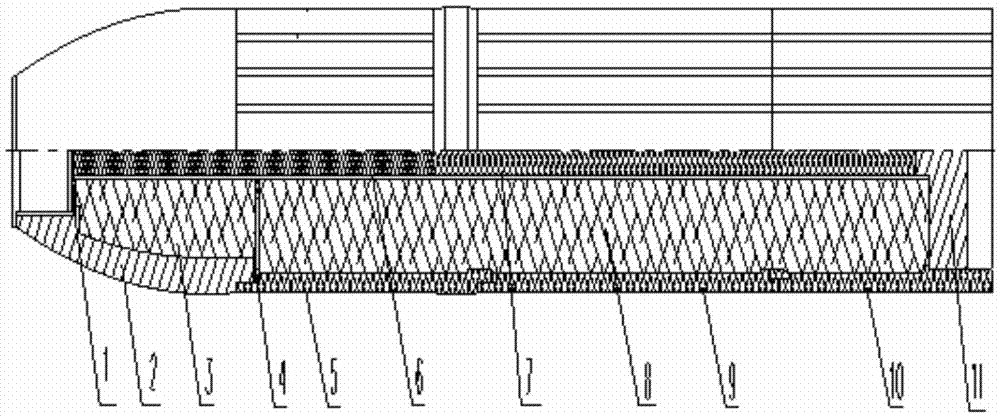

[0010] Such as figure 1 As shown, the warhead of the rocket fire extinguishing bomb of the present invention includes a pressure ring 1, a head screw 2, a head screw dry powder 3, a support plate 4, a center tube 6, a center burst tube 7, a fire extinguishing dry powder 8, a bomb bottom 11 and a body. The elastic body material adopts Bakelite. Projectile body is made of front projectile body 5, middle projectile body 9 and rear projectile body 10 three parts. The front projectile body 5, the middle projectile body 9 and the rear projectile body 10 all have a plurality of prefabricated through grooves. A plurality of prefabricated through grooves are evenly distributed along the circumferential direction of the projectile body, and the length direction of the prefabricated through grooves is along the axial direction of the projectile body. The front projectil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com