Tire pressure dynamic weighing device based on neural network

A neural network and dynamic weighing technology, applied in the application field of neural network analysis, can solve the problems of reducing production efficiency, low efficiency, and increasing operating costs of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

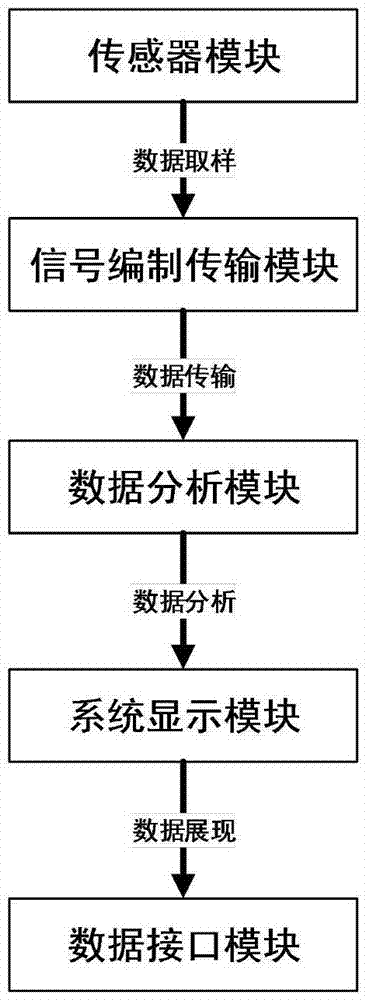

[0021] Such as figure 1 , a dynamic tire pressure weighing device based on neural network, the vehicle tire pressure and temperature information data are obtained through the sensor module, the data compilation and transmission module receives and stores the data transmitted by the sensor module, and then transmits the data to the data analysis module for neural network The data model analysis, and the final analysis and comparison results are displayed in the system display module.

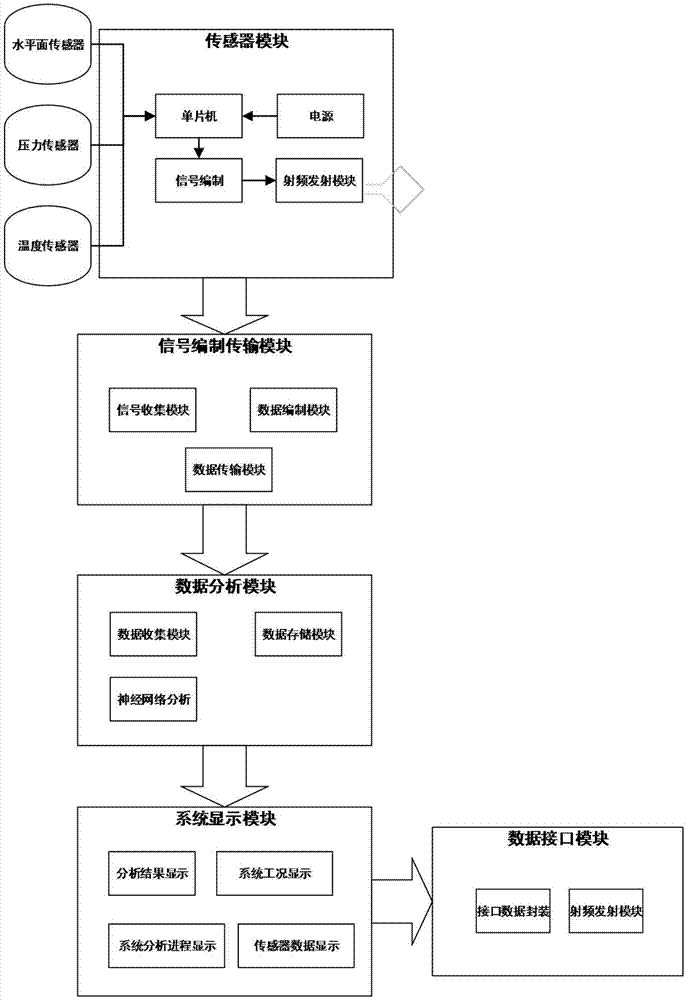

[0022] Such as figure 2 A neural network-based tire pressure dynamic weighing device is mainly composed of a sensor module, a data compilation and transmission module, a data analysis module, a system data display module and a data interface.

[0023] Among them, the sensor module module includes a pressure sensor and a temperature sensor. This module transmits the data obtained by the sensor to the single-chip microcomputer in the module for data compilation and preparation before transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com