Cover box

A technology for a sealing box and a box body, which is applied in the field of sealing boxes, can solve the problems of difficult quality control, high cost, time-consuming and labor-intensive, etc., and achieves the effects of simple structure, improved sealing efficiency and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

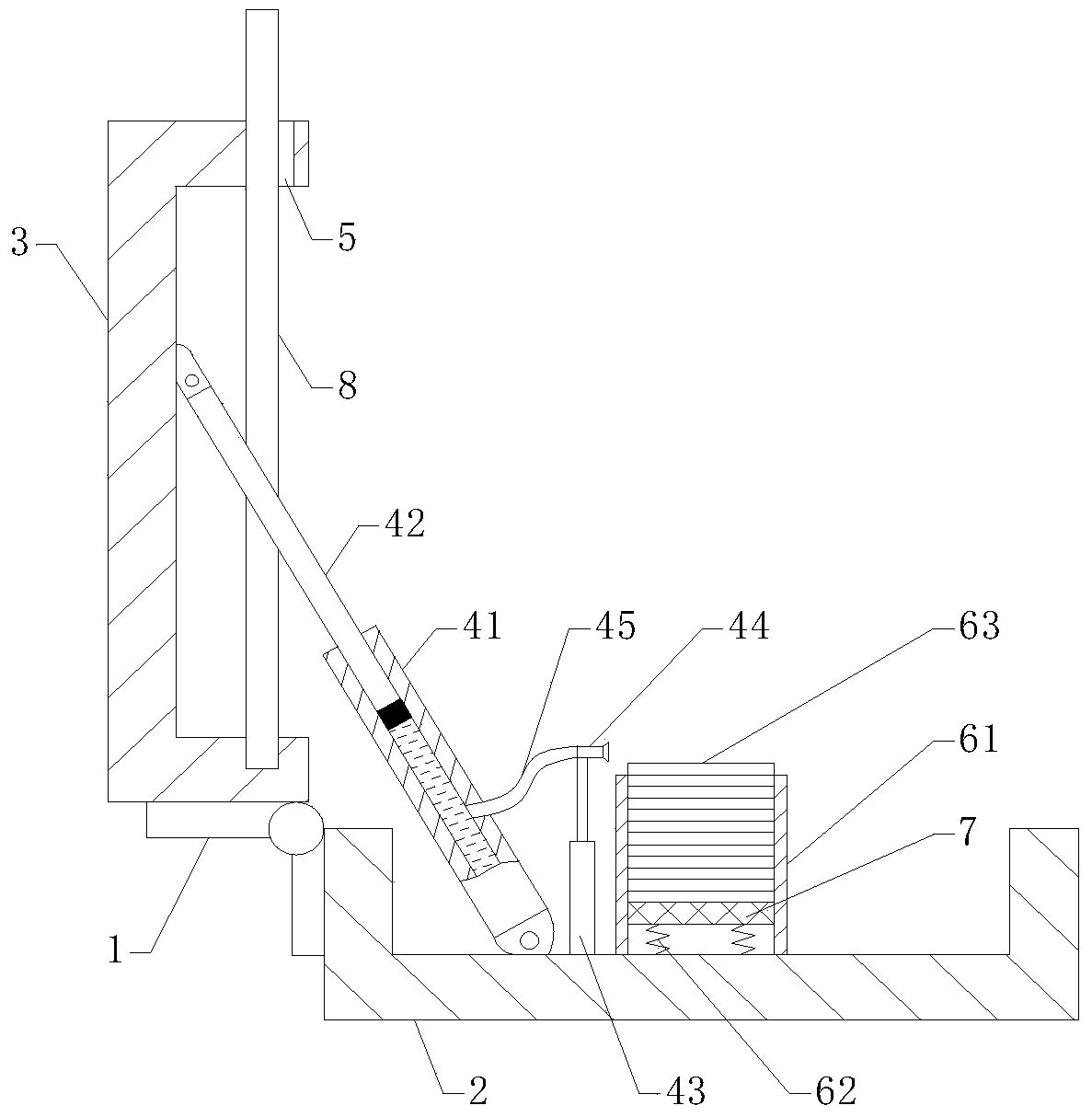

[0012] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: a sealing box, including a box body 2 and a box cover 3 hinged by a hinge 1, at least one set of sealing unit is arranged between the box body and the box cover, and the sealing unit includes resin dripping structure, the slide slide slot 5 arranged on the box cover and the cover glass pushing structure arranged in the box body, specifically, the resin dripping structure includes a cylinder 41 and a piston rod 42 sealingly sleeved with the cylinder , the free end of the cylinder is hinged to the bottom of the box body, the free end of the piston rod is hinged to the top of the box cover, resin is provided in the cylinder, and a support 43 is provided near the rectangular frame, the support The top is provided with a nozzle 44, and the nozzle communicates with the cylinder body through the rubber inlet tube 45. The cover glass pushing structure includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com