Device for testing mechanical response of surrounding rock and anchoring body under action of dynamic load and static load

A technology of mechanical response and test equipment, applied in the direction of measuring equipment, scientific instruments, instruments, etc., can solve problems such as limited support, cognitive deviation, and inability to simulate rockburst induced by dynamic impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

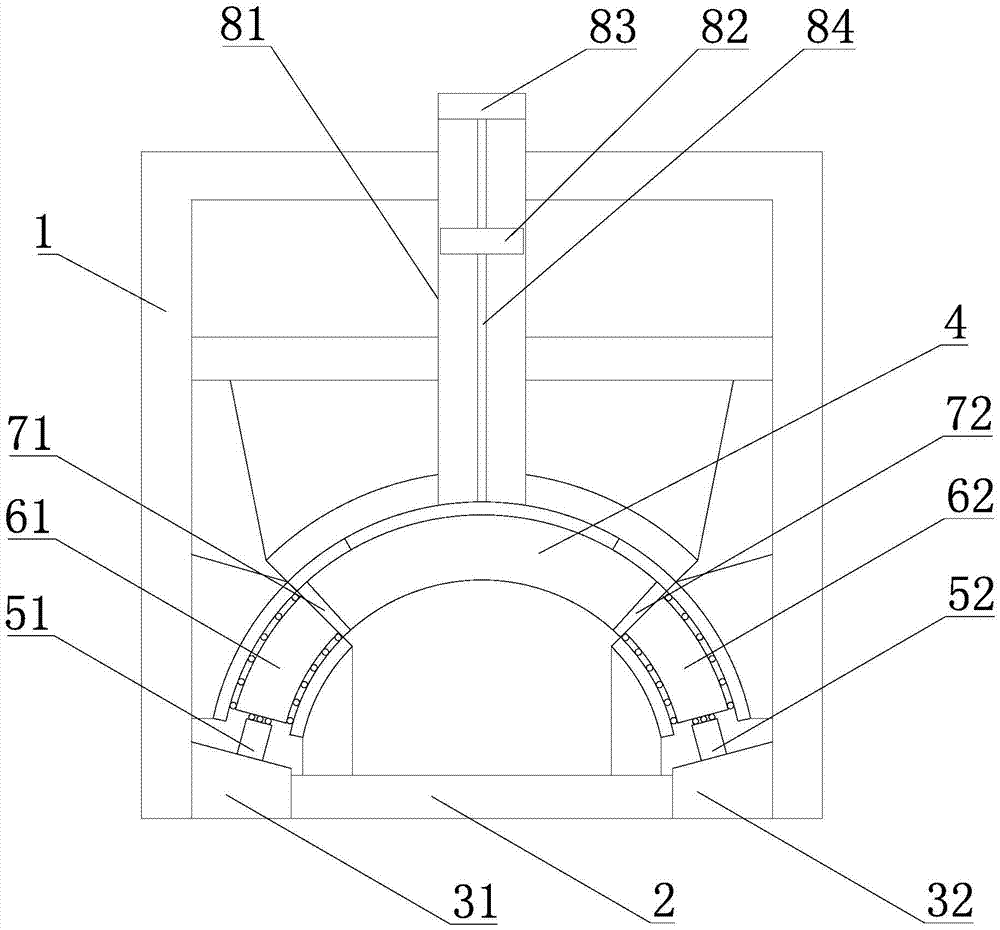

[0036] Such as Figure 1-3 As shown, the test device for the mechanical response of surrounding rock and anchorage under dynamic and static loads includes a frame 1 and an arc-shaped channel located in the frame 1. The bottom of the frame 1 is provided with a bottom support plate 21, and the arc-shaped The channel includes a sample channel 4 located in the middle of the arc and a left channel and a right channel located on the left and right sides of the sample channel 4. A sample 12 can be placed in the sample channel 4, and the sample 12 is The arch is installed between the left pad 71 and the right pad 72, and between the bottom support plate 21 is the hollow area 2 where the anchor rod 13 can be arranged, and the top limit plate is provided above the sample channel 4, and the top An impact load loading device is provided above the outer side of the limiting plate, and the impact load loading device provides a top-down impact load on the top of the top limiting plate, and t...

Embodiment 2

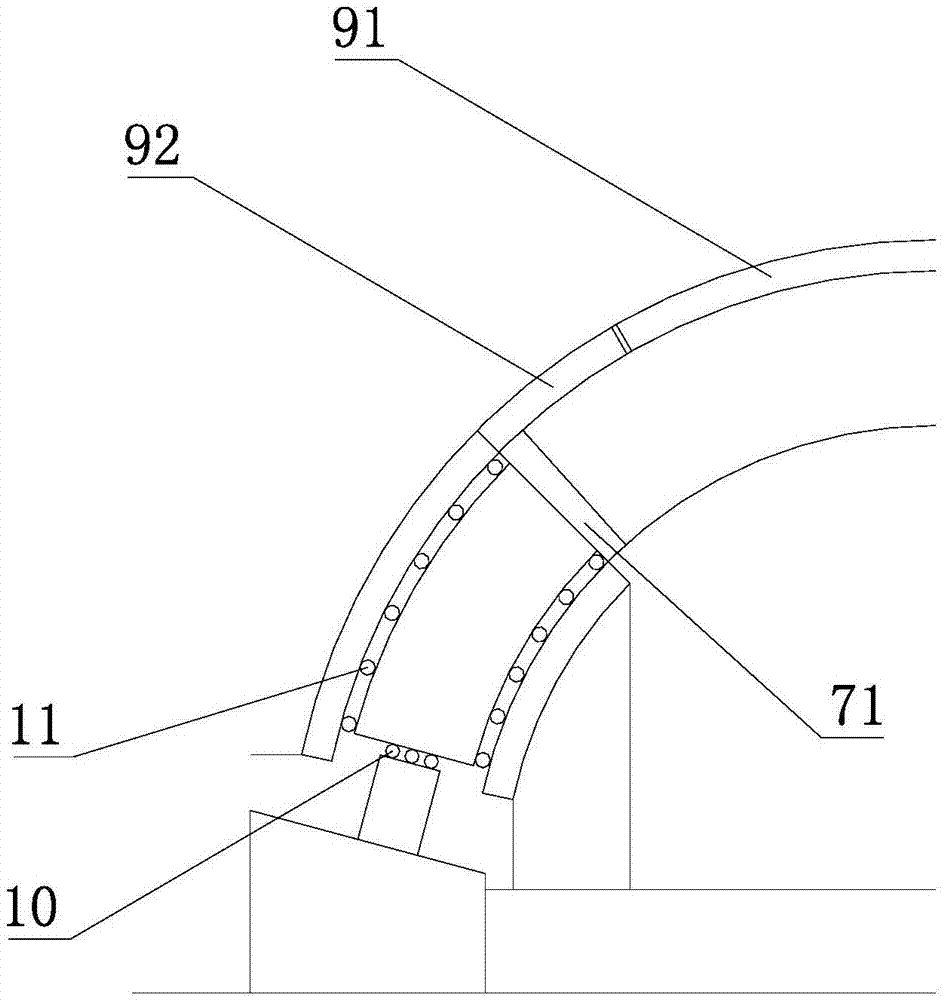

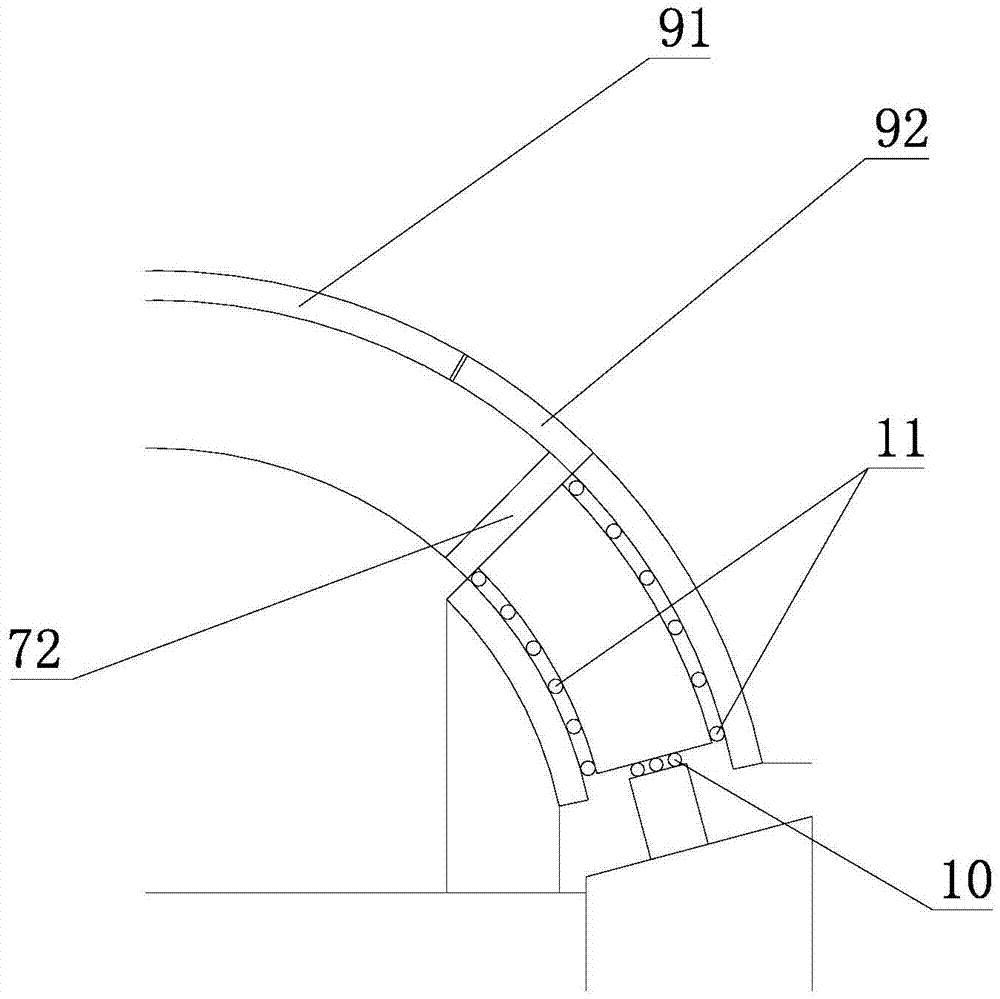

[0047] Such as Figure 4 As shown, on the basis of Example 1, the sample 12 is equipped with three anchor rods 13 according to the test plan, the upper surface of the left bearing plate 31 is parallel to the lower surface of the left force transmission plate 61, and the above two A left loading device is arranged between the surfaces, and the direction of the force exerted by the left loading device on the left force transmission plate is along the tangential direction of the left channel. Similarly, the upper surface of the right bearing plate 32 and the lower surface of the right force transmission plate 62 The surfaces are parallel, and a right loading device is arranged between the above two surfaces, and the direction of the force exerted by the right loading device on the right force transmission plate is along the tangential direction of the right channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com