Method for detecting thermal stability of battery separator

A detection method and battery diaphragm technology, applied in measuring devices, material thermal analysis, instruments, etc., can solve problems such as inaccurate reflection of thermal stability, and achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

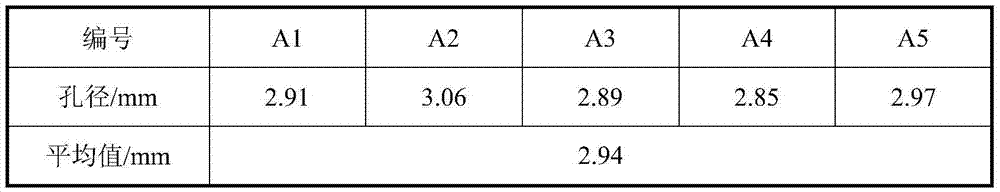

[0033] 1. Take a 12μm thick PP material separator and coat one side with 4μm thick AL 2 o 3 Material. Then mark the diaphragm as sample A, and cut it into 5 samples with a size of 100*50mm, which are marked as A1, A2, A3, A4, and A5 respectively;

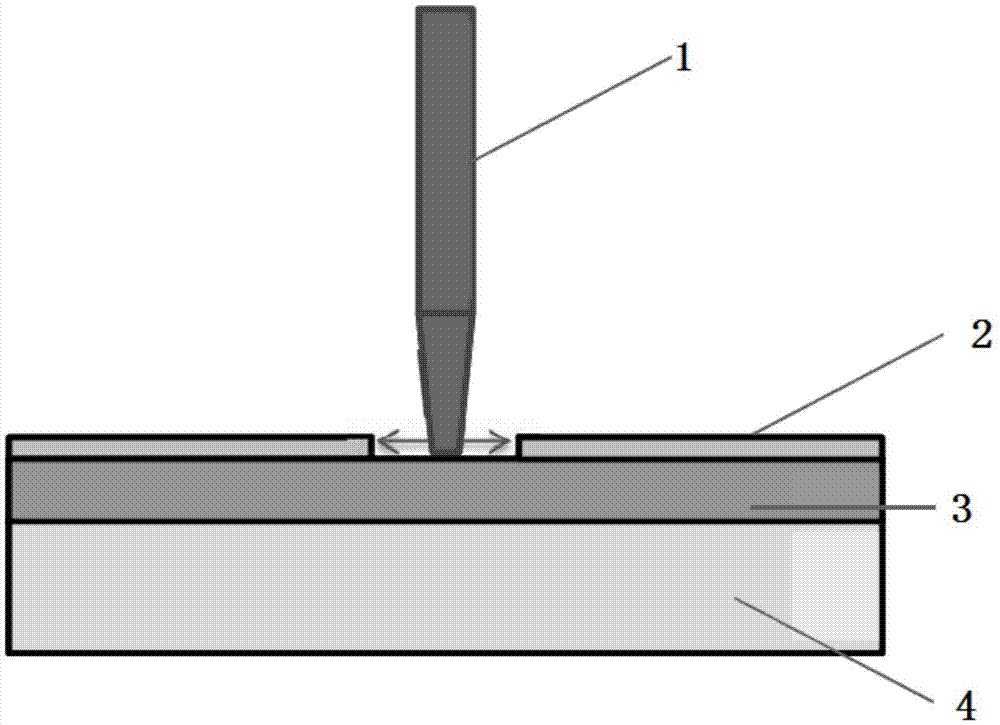

[0034] 2. Spread the 20 μm thick aluminum foil 3 on the smooth glass plate 1, and then spread the separator 2 on the aluminum foil 3, AL 2 o 3 The coated side faces up, and the two ends of the diaphragm are pressed with a pressing block to prevent the diaphragm from sliding during the test;

[0035] 3. Heat the surface temperature of soldering iron 1 with a φ of 1.0mm to 400°C and keep it for 10 minutes;

[0036] 4. Pierce the soldering iron 1 vertically towards the middle of the diaphragm sample 2, keep still, and remove the soldering iron along the vertical direction of the diaphragm after 5 seconds;

[0037] 5. Measure the diameter of the hole perforated by the soldering iron on the diaphragm with a two-dimensional imager, a...

Embodiment 2

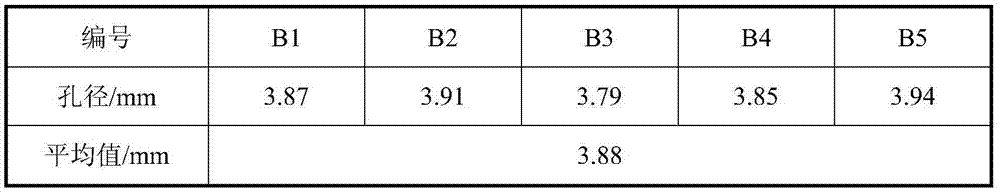

[0041] Take the 12 μm thick PP material base film of the same specification in Example 1, and coat it with 2 μm thick AL on both sides. 2 o 3 Material. Then mark the diaphragm as sample B, and cut it into five samples of 100*50mm size, which are respectively marked as B1, B2, B3, B4, and B5;

[0042] According to the test method in Example 1, sample B was subjected to hot-smelting experiments, and recorded in Table 2.

[0043] Table 2 Test results of sample B hot-soldering experiment

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com