Submarine cable joint of different armoured structures and online transition process therefor

A submarine cable and armoring technology is applied in the field of submarine cable joints and their online transition technology to achieve the effects of reducing installation cost and difficulty, improving reliability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

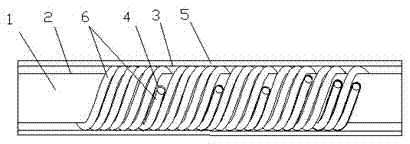

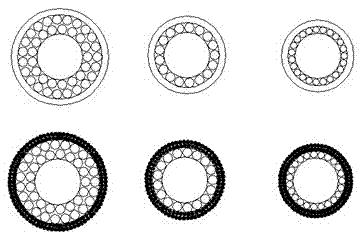

[0039] The invention discloses a cable-type transition joint for a submarine cable, which sequentially includes a cable core 1, an asphalt coating 2, a cable-type transition end, an adhesive tape 3 and the outermost cladding layer from the inside to the outside; the cable core 1 is an integral root, with the same outer diameter, running through the entire submarine cable, the asphalt coating 2 is coated on the cable core at the joint of the cable-type transition end; the cable-type transition end includes the transition end of the A cable type and the B cable type The transition end of the A cable type is an unarmored submarine cable, and the B cable type is an armored submarine cable with more than one layer of armor. The steel wire end at the connection between the B cable transition end and the A cable transition end There is also a connecting pipe 4, that is, a heat-shrinkable tube; the outermost coating layer is an asphalt coating and a PP rope or PE sheath 5 coated outsid...

Embodiment 2

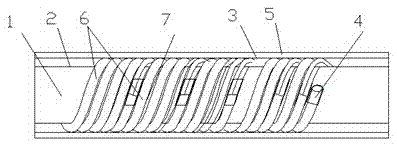

[0050]The invention discloses a cable-type transition joint of a submarine cable, which sequentially includes a cable core 1, an asphalt coating 2, a cable-type transition end, an adhesive tape 3 and the outermost cladding layer from the inside to the outside; the cable core 1 is an integral root, with the same outer diameter, running through the entire submarine cable, and the asphalt coating 2 is coated on the cable core at the joint of the cable-type transition end; the cable-type transition end includes the transition end of the A cable type and the B cable type The transition end of type A and type B are both armored submarine cables, and the number of armor layers is more than 1. The number and diameter of steel wires of type A and type B are different. The steel wire welded joint at the connection of the cable-type transition end is also sleeved with a connecting pipe 4, that is, a high-strength casing; the outermost cladding layer is an asphalt coating and a PP rope or ...

Embodiment 3

[0062] The invention discloses a cable-type transition joint of a submarine cable, which sequentially includes a cable core 1, an asphalt coating 2, a cable-type transition end, an adhesive tape 3 and the outermost cladding layer from the inside to the outside; the cable core 1 is an integral root, with the same outer diameter, running through the entire submarine cable, and the asphalt coating 2 is coated on the cable core at the joint of the cable-type transition end; the cable-type transition end includes the transition end of the A cable type and the B cable type Type A and Type B are armored submarine cables, the number of steel wires of Type A and Type B is different, and the number of layers of steel wires of Type B is at least 1 layer greater than that of Type A. The diameter and number of steel wires in the same part of the A-cable type and B-cable type are the same, and a connecting pipe 4 is sleeved on the welded joint of the steel wire at the junction of the transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com