Dual-seesaw supporting mechanism and thin word key

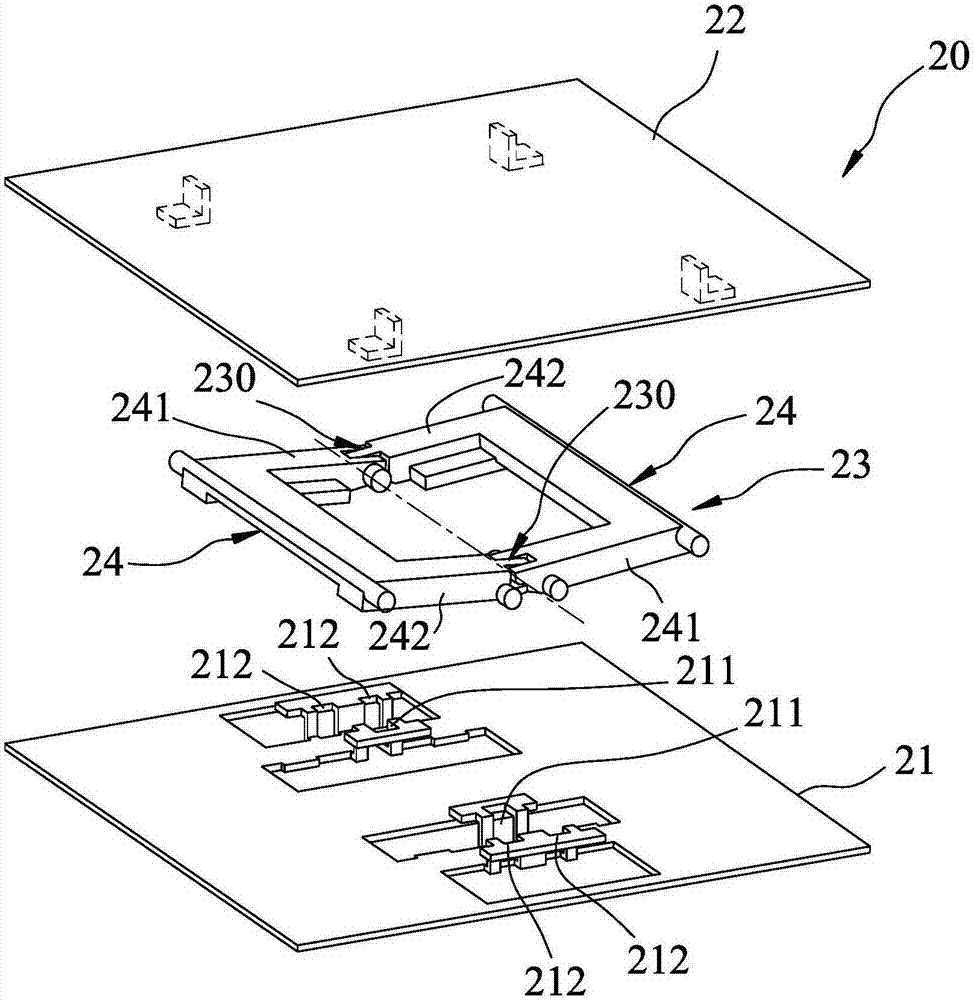

A support mechanism and double rocker type technology, applied in the direction of electrical components, emergency actuators, electric switches, etc., can solve the problems of poor structural strength of the gear hinge 230, complex structure of the bottom plate 21, high production cost, etc., and achieve good structural strength , Reduce production costs, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

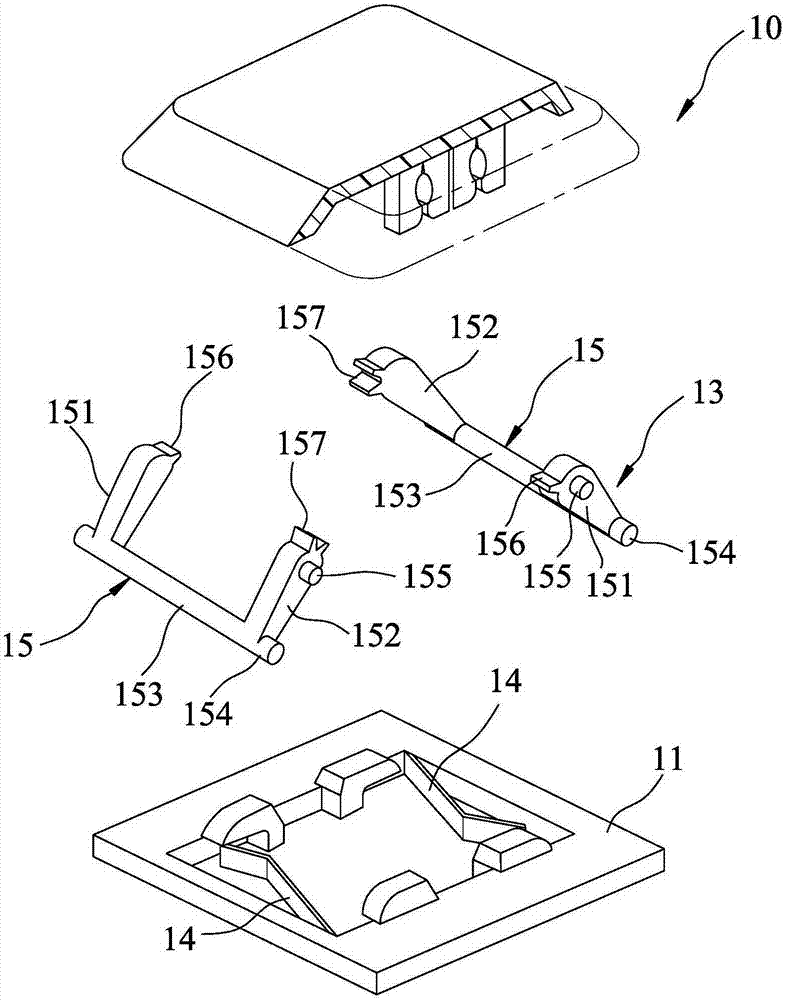

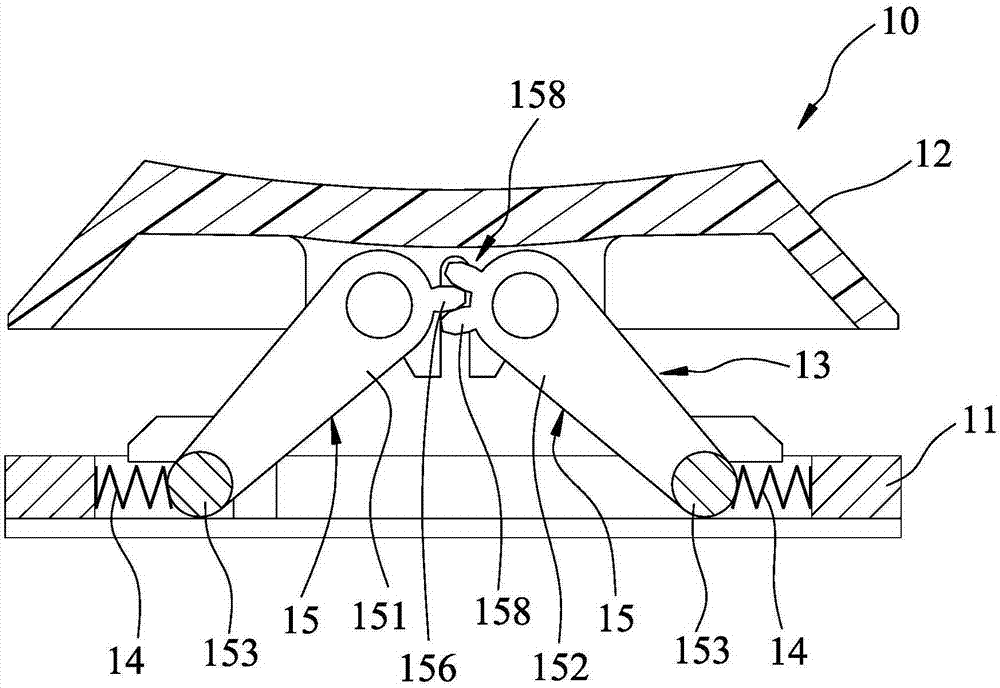

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] Before the present invention is described in detail, it should be noted that the relative position terms used in the following descriptions, such as "front", "rear", "left", "right", "top", and "bottom", are based on The directions shown in the pictures and the normal use directions are for reference.

[0039] refer to Figure 5 An embodiment of the thin keypad of the present invention includes a bottom plate 30 , a keycap 40 , a pair of seesaw-type support mechanisms 5 , a circuit board 80 , an insulating film 90 and an elastic member 100 .

[0040] The bottom plate 30 includes two left pivot lug groups 31 and two right pivot lug groups 32 respectively formed towards the top side. The pivot holes 311 and the right pivot ear groups 32 are aligned along the front-rear direction, and each right pivot ear group 32 includes a right pivot hole 321 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com