Distributed-contact moving contact device

A moving contact, distributed technology, applied in the direction of circuit breaker contacts, circuit breaker components, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of improving contact stability, increasing effective contact area, and increasing conductive current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

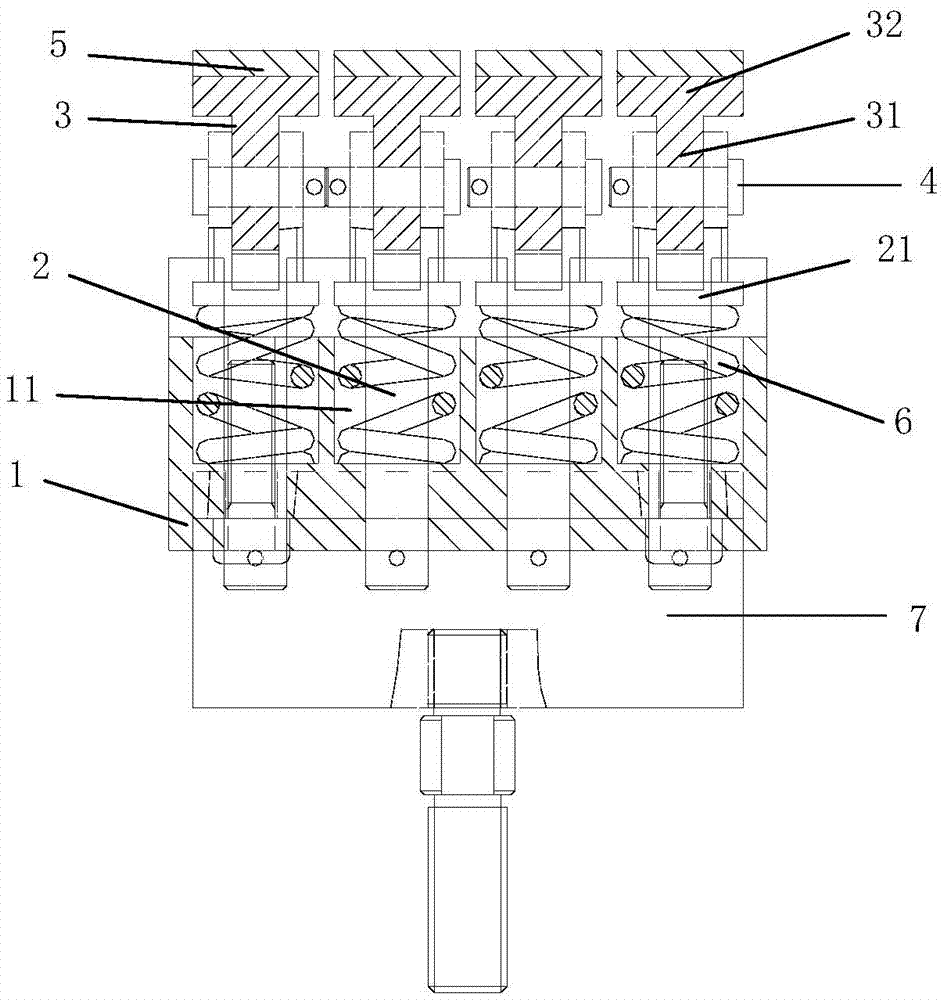

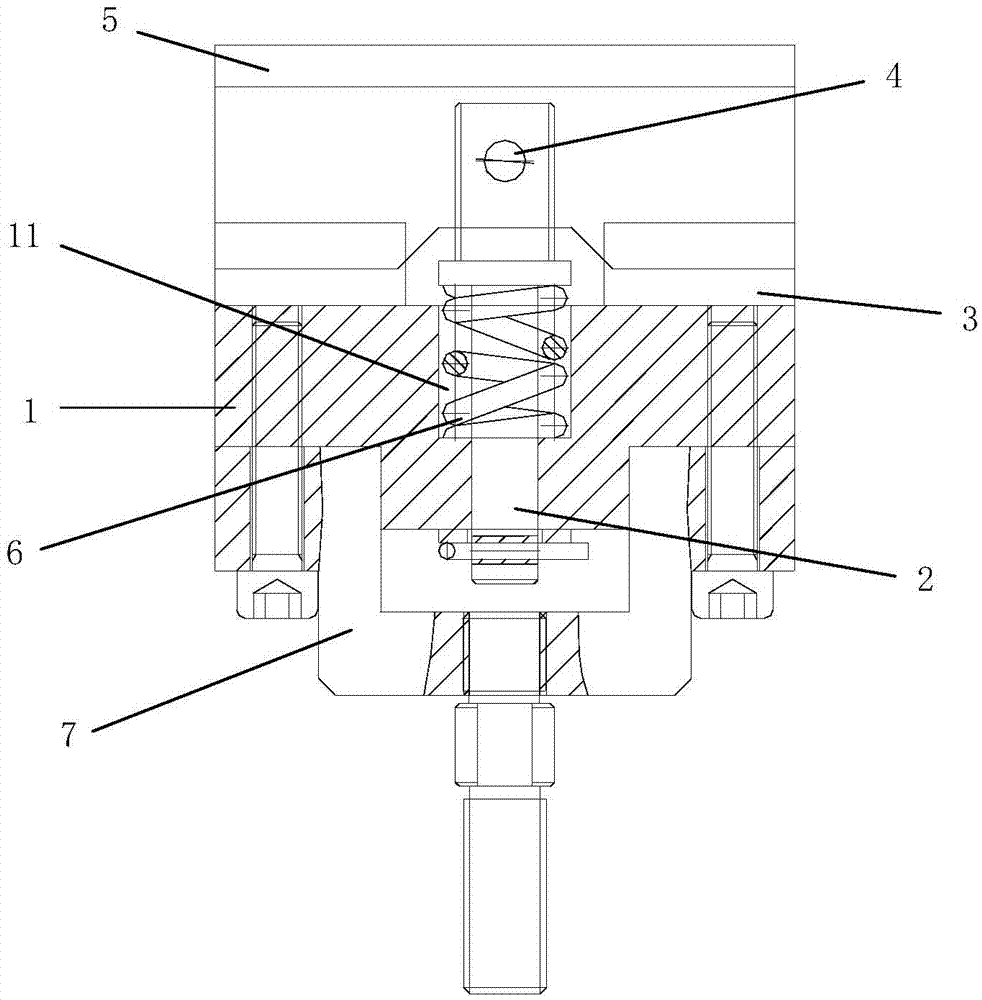

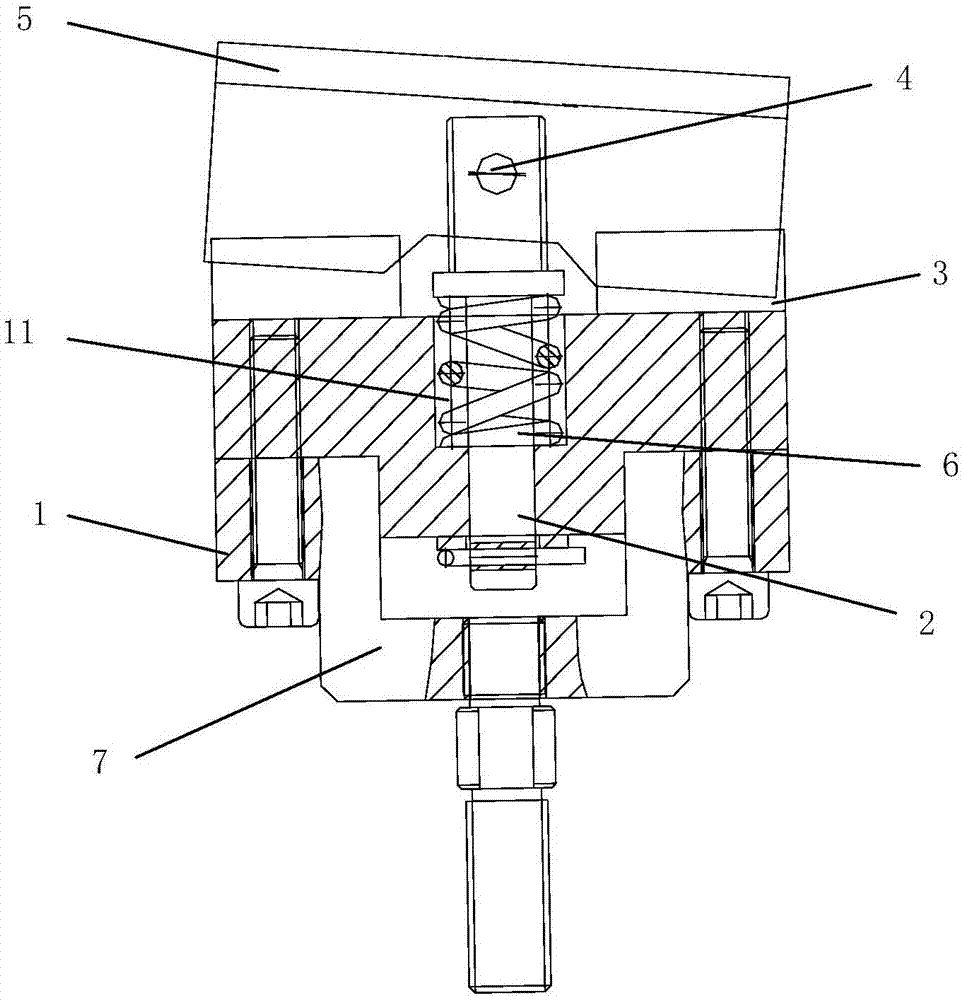

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments: Please refer to Figure 1-3 , the present invention relates to a distributed contact moving contact device, and its preferred embodiment includes a contact seat 1, a plurality of contact shafts 2, a plurality of conductive sheet seats 3, a plurality of pivot shafts 4 and a plurality of conductive sheets 5; each The lower end of the contact shaft 2 is installed in the contact seat 1, the upper end of each contact shaft 2 extends upwards out of the contact seat 1, and several contact shafts 2 are distributed at intervals along the length direction of the contact seat 1; each contact The upper end of the shaft 2 is pivotally connected to a corresponding conductive sheet seat 3 through a corresponding pivot shaft 4, and the axis of the pivot shaft 4 is perpendicular to the axis of the contact shaft 2, and the conductive sheet seat 3 can swing around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com