Auxiliary pressure welding tooling for shielding net conduction joint of shielding line

A technology of shielded net and shielded wire, which is applied in the connection, circuit/collector parts, electrical components, etc., can solve the problems such as the loss of shielding function of the shielding net, the disconnection of the conduction joint of the shielding net, and the malfunction of automobile electrical appliances. The connection structure is simple and reliable, the volume is small, and the quality is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

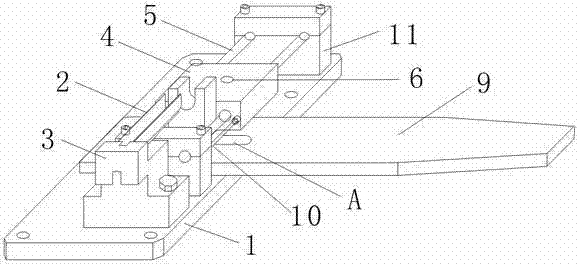

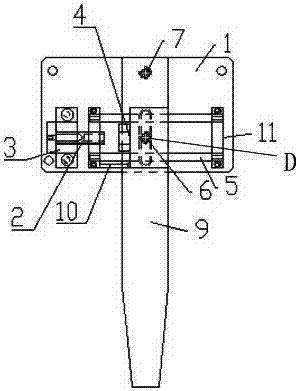

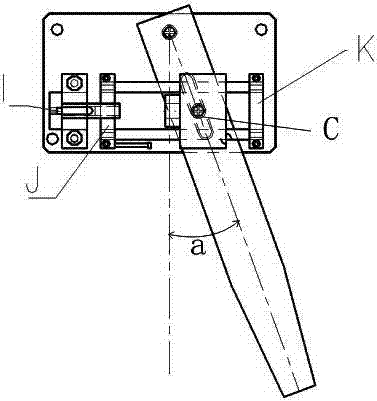

[0023] figure 1 , 2 , 3, and 4, the base 1 is provided with a fixture support structure 3 that provides crimping force for the limit rubber parts, a crimping module 4 for crimping the conductive joint, and a guide rod 5 for controlling the sliding direction of the crimping module. The torque handle 9 that drives the crimping module to slide along the guide assembly, and the travel limit pin 10 that controls the stroke of the crimping module. The jig support structure 3 and the support structure 11 for fixing the guide rod are fixed on the base 1 by bolts. The guide rod supporting structure 11 is divided into left and right parts, and the left part J has the same structure as the right part K. The left part J is divided into upper and lower steel parts, and the middle part is connected and fixed on the base 1 by half-wire bolts. The upper and lower sides of the upper and lower steel parts of the left part J are provided with Φ12 semicircular grooves, so that the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com