Discharge circuit for preventing voltages of batteries from flowing backwards and control method

A discharge circuit and battery voltage technology, applied in battery circuit devices, safety/protection battery circuits, charge equalization circuits, etc., can solve problems such as potential safety hazards and inability to discharge in time, so as to improve safety, avoid excessive discharge, and prevent battery The effect of voltage backfeeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

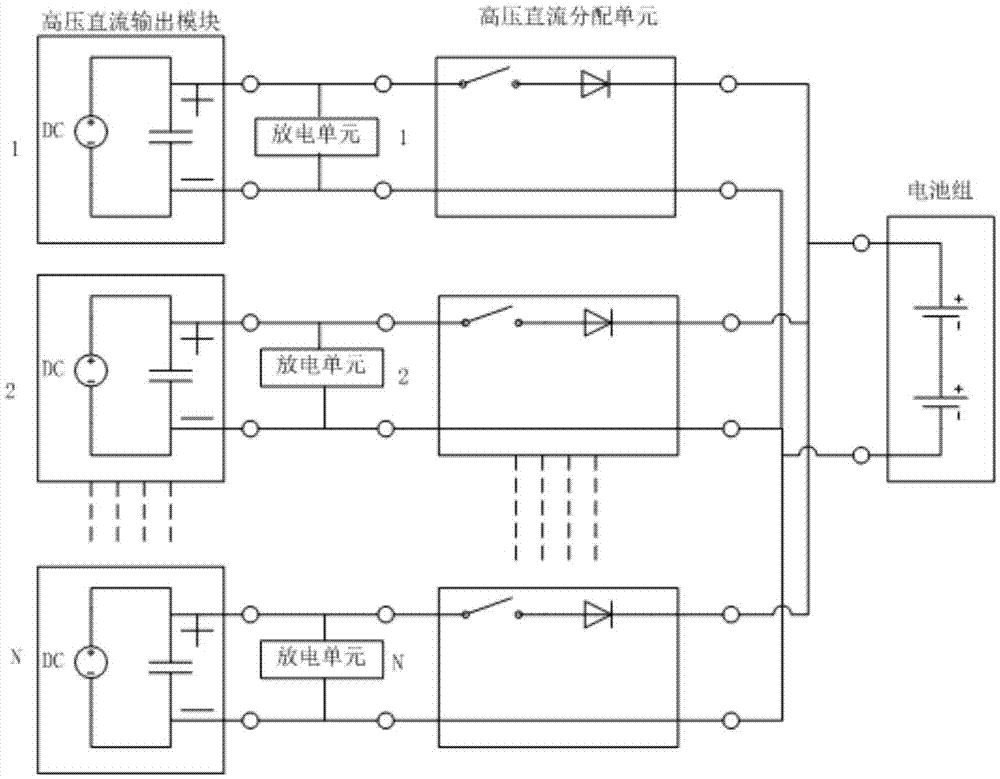

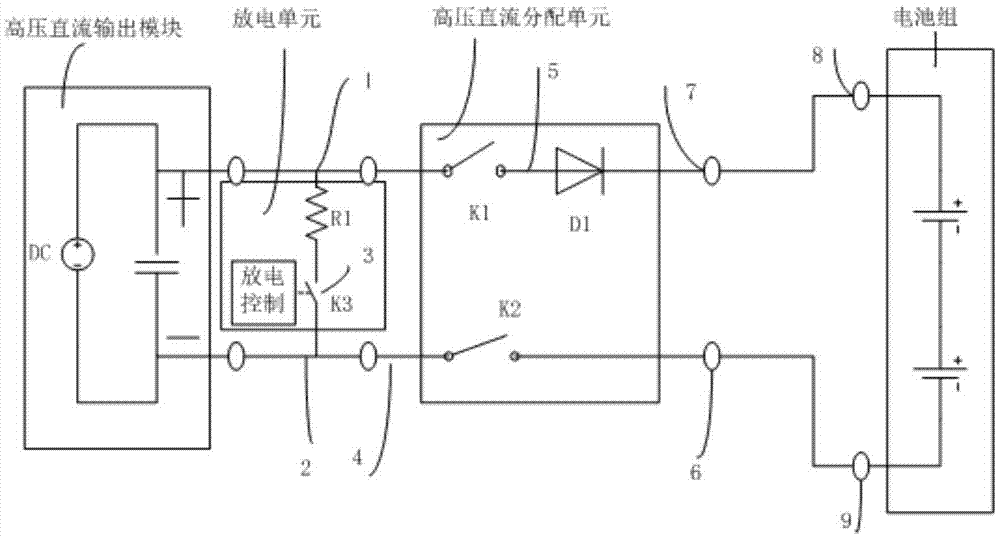

[0026] see figure 1 and figure 2 , a discharge circuit for preventing battery voltage backfeeding, comprising at least one high-voltage direct current output module with positive and negative poles, each high-voltage direct-current output module is connected to its corresponding high-voltage direct-current distribution unit, and the high-voltage direct-current output module and the high-voltage direct-current distribution unit are connected Discharge units are connected in parallel, and all high-voltage DC distribution units are connected to battery packs;

[0027] The discharge unit includes a power resistor R1 and a discharge switch K3 connected in series, the power resistor R1 is connected to the positive pole of the high-voltage DC output module, and the other end of the discharge switch K3 is connected to the negative pole of the high-voltage DC output module;

[0028] The high-voltage DC distribution unit includes a first switch K1 connected to the positive pole of the...

Embodiment 2

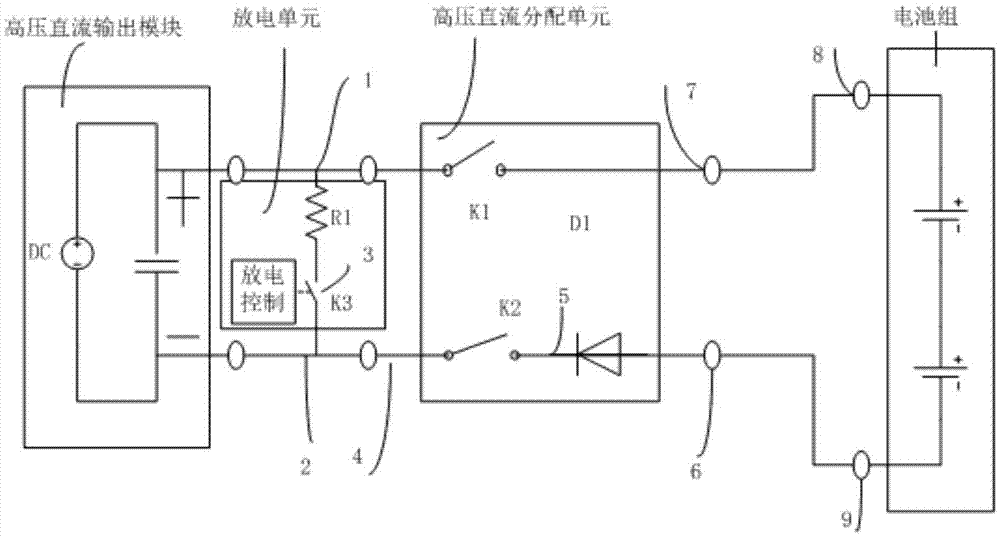

[0030] see image 3 , a discharge circuit for preventing battery voltage backfeeding, comprising at least one high-voltage direct current output module with positive and negative poles, each high-voltage direct-current output module is connected to its corresponding high-voltage direct-current distribution unit, and the high-voltage direct-current output module and the high-voltage direct-current distribution unit are connected Discharge units are connected in parallel, and all high-voltage DC distribution units are connected to battery packs;

[0031] The discharge unit includes a power resistor R1 and a discharge switch K3 connected in series, the power resistor R1 is connected to the positive pole of the high-voltage DC output module, and the other end of the discharge switch K3 is connected to the negative pole of the high-voltage DC output module;

[0032] The high-voltage direct current distribution unit includes a first switch K1 connected to the positive pole of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com