Brushless direct-current motor

A DC motor and motor shaft technology, applied in the field of electric motors, can solve problems such as unsuitable for manned aircraft, complex structure, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below:

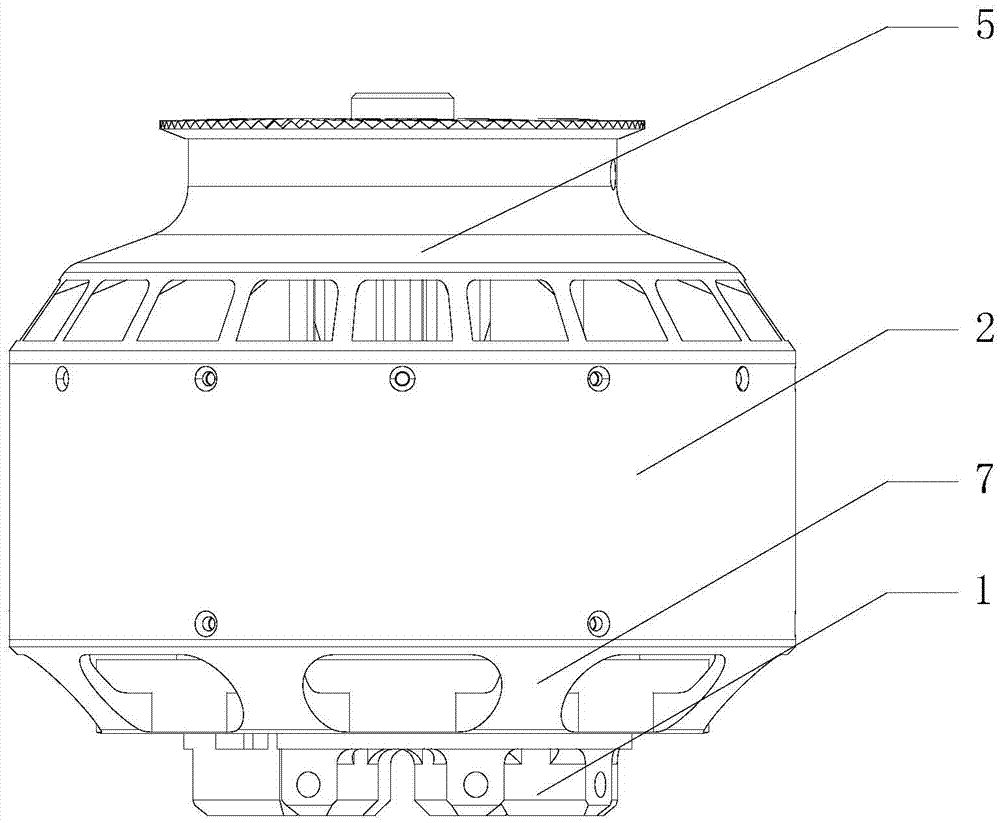

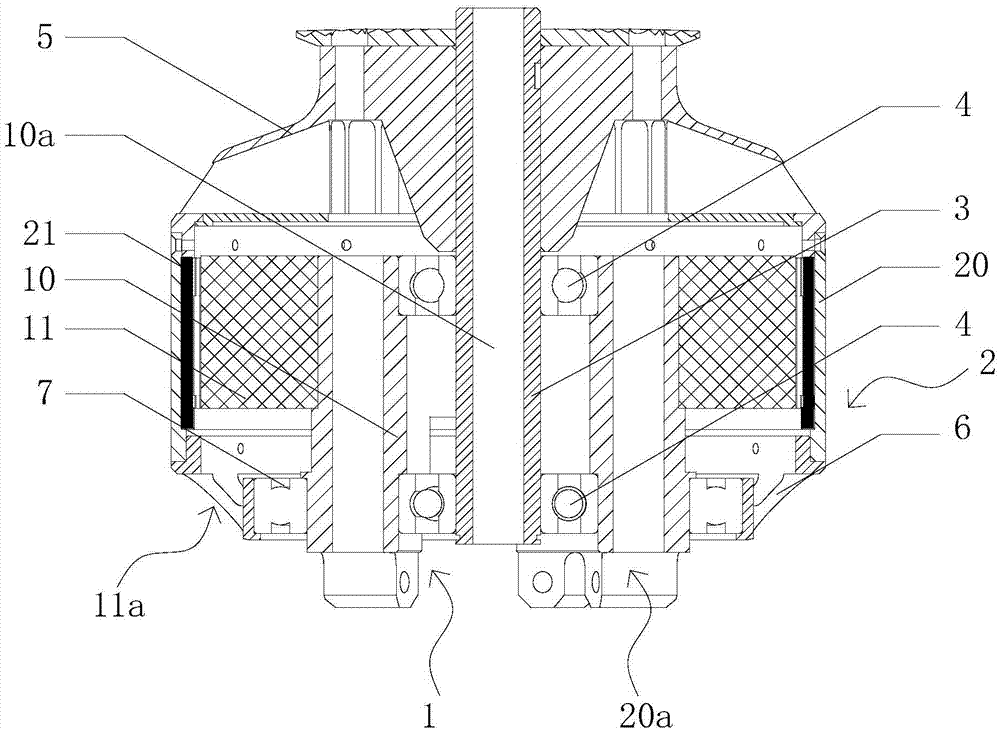

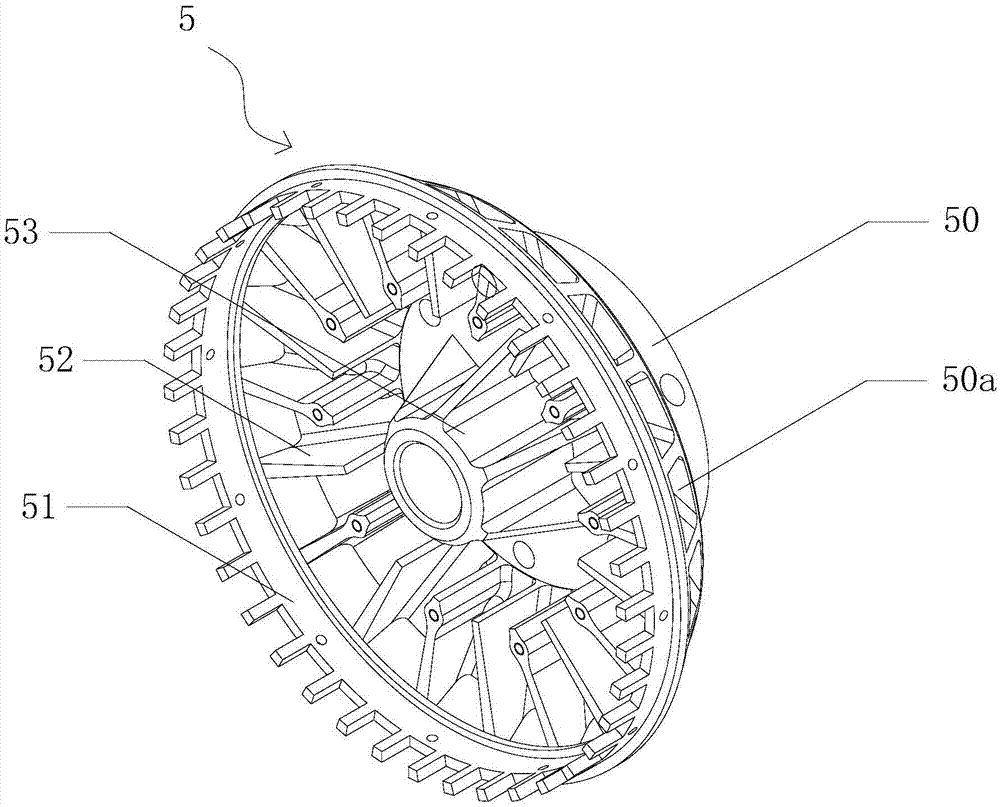

[0024] Such as figure 1 , 2 As shown, the brushless DC motor described in this embodiment includes a stator 1, a rotor 2 that can rotate relative to the stator 1, and a motor shaft 3 that is fixedly connected to the rotor 2. The stator 1 includes a stator core 10 and an excitation winding 11. The field winding 11 is arranged on the stator core 10, the rotor 2 includes a rotor yoke 20 and at least two magnets 21, and the magnets 21 are arranged on the rotor yoke 20 at intervals, and the field winding 11 and The magnets 21 are arranged opposite to each other and leave an annular first cooling channel 11 a . The stator core 10 is provided with a plurality of second cooling channels 20 a , and the second cooling channels 20 a are arranged along the axial direction of the stator core 10 . The above brushless DC motor, when the current flows through the field winding 11, will generate a rotating magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com