Flexible printed circuit board and fabrication method thereof

A technology of flexible circuit boards and circuit boards, which is applied in the direction of printed circuits, printed circuits, printed circuit components, etc., to achieve the effect of simplifying the connection steps and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

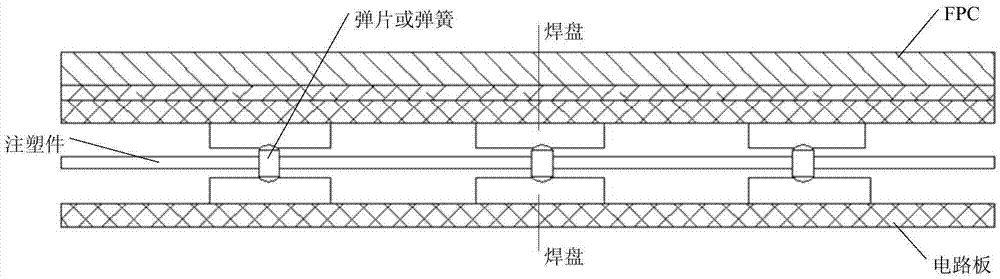

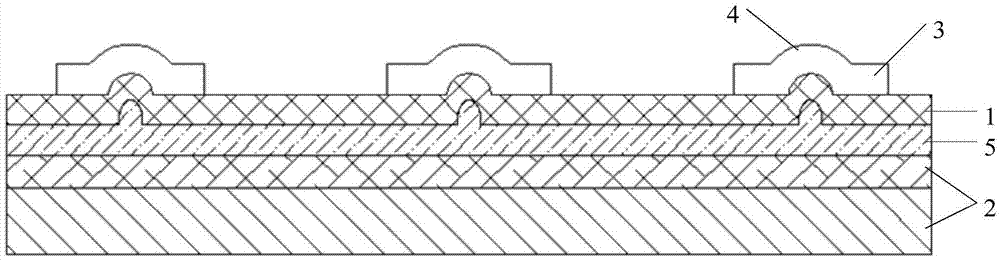

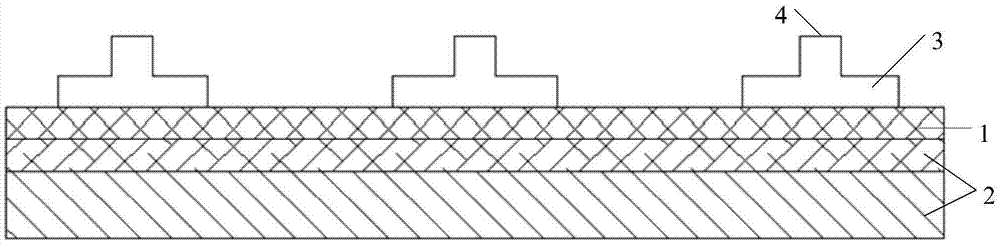

[0042] figure 2 A cross-sectional schematic diagram of a flexible circuit board with arched protrusions provided in this embodiment, image 3 A cross-sectional schematic diagram of a flexible circuit board with cylindrical protrusions provided for this embodiment.

[0043] refer to figure 2 and image 3 As shown, the flexible circuit board of this embodiment includes a substrate 1, copper foil and a reinforcing part 2, the copper foil covers the upper surface of the substrate 1, and a circuit layer and a plurality of pads 3 are formed on the copper foil; the reinforcing part 2 is bonded to The lower surface of the substrate 1 is used to strengthen the strength of the flexible circuit board;

[0044] At least one bump 4 is provided on each pad 3 of the flexible circuit board in this embodiment;

[0045] The pads 3 of the flexible circuit board contact the pads of another circuit board through the bumps 4 thereon, so as to realize the electrical connection between the flex...

Embodiment 2

[0074] This embodiment provides a method for preparing the flexible circuit board in Embodiment 1.

[0075] Figure 6 The flow chart of the preparation method of the flexible circuit board provided in this embodiment, as Figure 6 as shown, Figure 6 The methods in include:

[0076] S610, covering the upper surface of the substrate with copper foil, and forming a circuit layer and several pads by etching the copper foil.

[0077] S620, providing at least one bump on each pad.

[0078] S630, adhering a reinforcing part to strengthen the strength of the flexible circuit board on the lower surface of the substrate.

[0079] In this embodiment, protrusions are provided on the pads of the flexible circuit board, so that the flexible circuit board can directly contact the pads of other circuit boards through the protrusions on the pad, so as to realize the electrical connection between the flexible circuit board and other circuit boards. connect.

[0080] The method for prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com