Valve Assemblies for Clutch Systems

A technology of valve components and clutches, applied in the field of clutch systems, which can solve the problems of valves no longer closing safely and completely, disturbing noise development, unclear internal leakage of active cylinders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

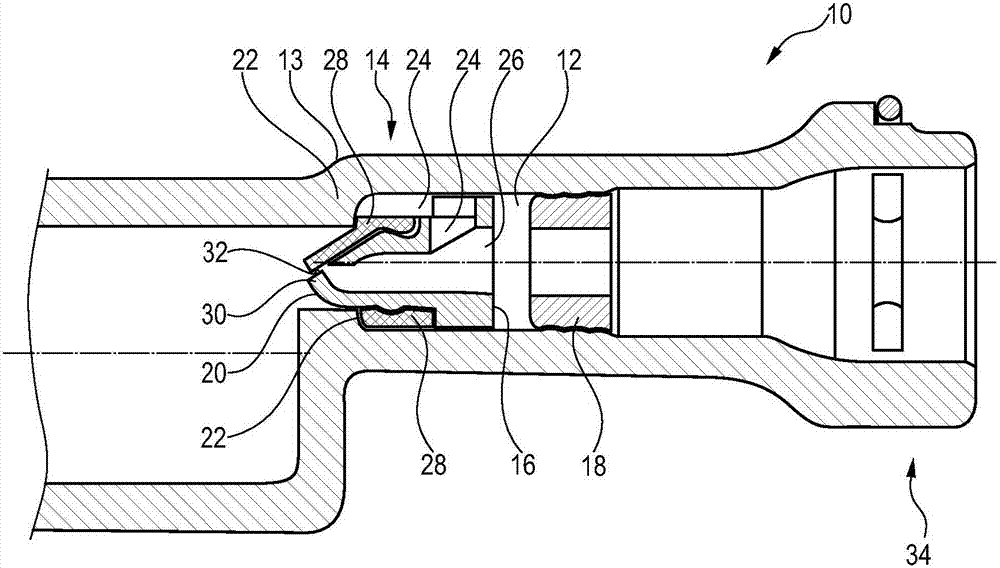

[0036] exist figure 1 Valve assembly 10 is shown in . The valve assembly 10 can be used in particular in hydraulically actuatable clutch systems, such as in particular engaging or disengaging systems. In this case, the valve assembly 10 can be arranged in a freely selectable area of the clutch system, for example in the high-pressure area of the engaging or disengaging system, lines, torque limiters (PTL), adapters, shock absorbers, clutch slaves, etc. Moving parts such as CSC or other components.

[0037] The valve assembly 10 comprises a channel 12 for the pressure-tight conduction of hydraulic fluid. A valve body 14 is arranged in the channel 12 . according to figure 1 , the channel 12 is delimited by a housing 13 which is an integral part of the master cylinder. Here, the circumference of the valve body 14 is expediently matched at least partially in shape and size to the inner circumference of the housing 13 or to the geometry of the channel 14 , so that a sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com