Cleaning notches and passages for a feeding or refining element

A notch and feeding technology, applied in the fields of application, textile and papermaking, fiber raw material processing, etc., can solve the problems of reducing the attractiveness and sales value of the final product, and achieve the effect of eliminating fiber accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

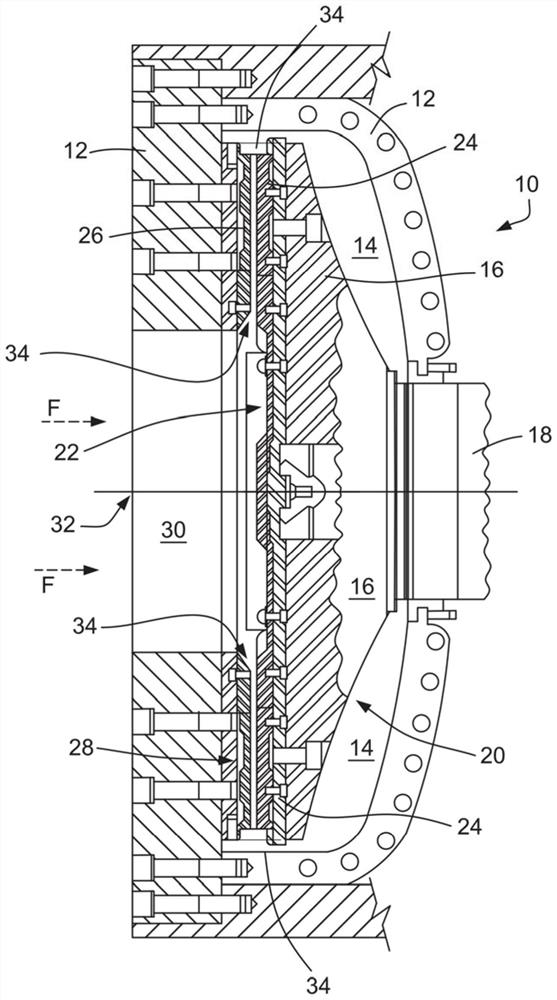

[0023] FIG. 1 shows a cross-section of a conventional single-disk refiner 10 having a housing 12 defining an internal chamber 14 . The rotor disk assembly 16 in the chamber is turned by a shaft 18 driven by a motor. The rotor disk assembly comprises an annular assembly of a support disk 20 , a circular flinger plate 22 attached to the front face of the support disk 20 and a pie-shaped refiner plate segment 24 mounted to the front face of the support disk 20 . The inner edge of the refiner plate segment is adjacent to the outer periphery of the slinger plate 22 .

[0024] A similar annular array of plate segments 26 is arranged on a support disc 28 of the stator disc assembly fixed to the housing. Alternatively, annular refiner plates may be used instead of an annular array of plate segments. Furthermore, the refiner plates or plate segments may be arranged in pans that generally conform to the plane of a disc refiner, or as frusto-conical plates or frusto-cones for plate seg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com