Polyolefin rheological master batch-PPA and preparation method thereof

A technology of polyolefin and master batch, applied in the field of pure natural composition, can solve the problems of oral film accumulation, insufficient fluidity of screw material, and substandard physical performance indicators of polyolefin film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A polyolefin rheological masterbatch-PPA, the polyolefin rheological masterbatch-PPA is made of the following raw materials in parts by mass:

[0043] Linear polyethylene powder 91g, polyphthalamide 3g, composite antioxidant 0.2g, polyethylene paraffin 1g, paraffin 0.5g.

[0044] Wherein, the air-invigorating auxiliary material includes the following raw material components: 0.066 g of hindered phenolic antioxidant and 0.133 g of phosphate antioxidant.

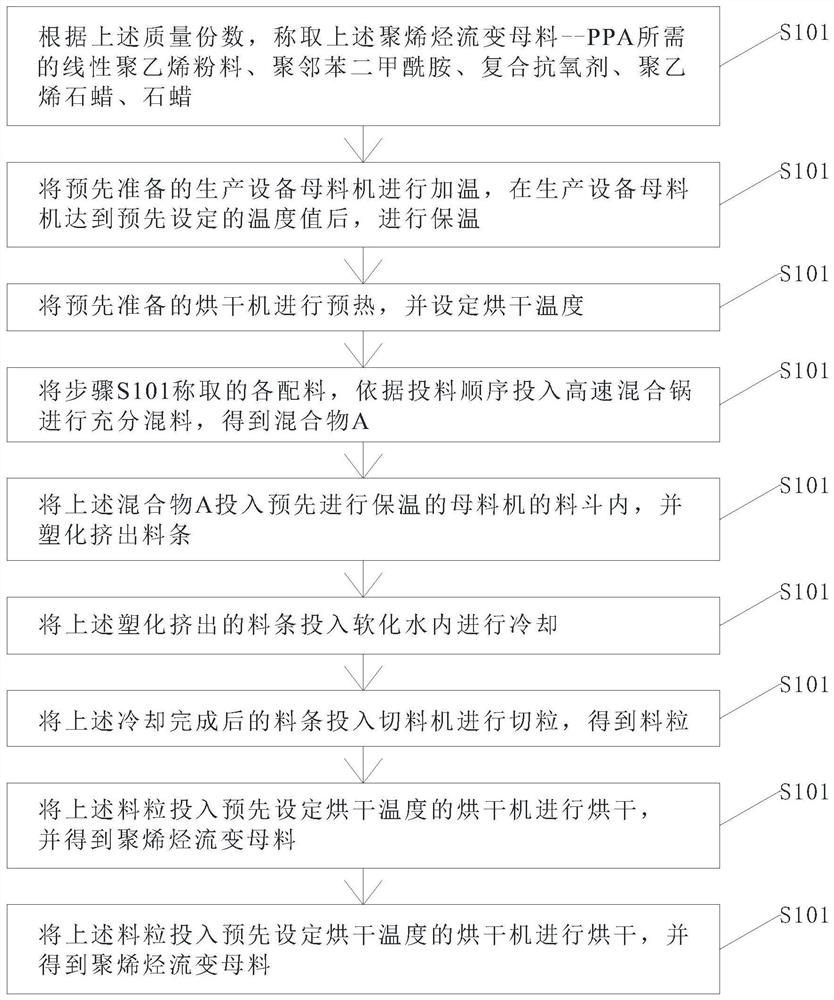

[0045] The preparation for polyolefin rheological masterbatch-PPA includes the following steps:

[0046] S101, according to the above-mentioned mass parts, weigh 91g of linear poly-linear polyethylene powder, 3g of polyphthalamide, 0.2g of composite antioxidant, and 1g of polyethylene paraffin required for the above-mentioned polyolefin rheological masterbatch-PPA , paraffin 0.5g;

[0047] S102, heating the pre-prepared production equipment masterbatch machine, and keeping warm after the production equipment masterbat...

Embodiment 2

[0056] A polyolefin rheological masterbatch-PPA, the polyolefin rheological masterbatch-PPA is made of the following raw materials in parts by mass:

[0057] Linear polyethylene powder 92g, polyphthalamide 4g, composite antioxidant 0.25g, polyethylene paraffin 1.5, paraffin 0.75g.

[0058] Wherein, the composite antioxidant includes the following raw material components: 0.083 g of hindered phenolic antioxidant and 0.166 g of phosphate antioxidant.

[0059] The preparation of this polyolefin rheological masterbatch-PPA comprises the following steps:

[0060] S101, according to the above mass parts, weigh 92g of linear polyethylene powder, 4g of polyphthalamide, 0.25g of composite antioxidant, 1.5g of polyethylene paraffin wax, paraffin wax 0.75g;

[0061] S102, heating the pre-prepared production equipment masterbatch machine, and keeping warm after the production equipment masterbatch machine reaches a preset temperature value;

[0062] S103, preheating the pre-prepared drye...

Embodiment 3

[0070] A polyolefin rheological masterbatch-PPA, the polyolefin rheological masterbatch-PPA is made of the following raw materials in parts by mass:

[0071] 93g of linear polyethylene powder, 5g of polyphthalamide, 0.3g of composite antioxidant, 2g of polyethylene paraffin, and 1g of paraffin.

[0072] Wherein, the composite antioxidant includes the following raw material components: 0.1 g of hindered phenolic antioxidant and 0.2 g of phosphate antioxidant.

[0073] The preparation of this polyolefin rheological masterbatch-PPA comprises the following steps:

[0074] S101, according to the above-mentioned mass parts, weigh 93g of linear polyethylene powder required for the above-mentioned polyolefin rheological masterbatch-PPA, polyphthalamide 5g, composite antioxidant 0.3g, polyethylene paraffin 2g, paraffin wax 1g;

[0075] S102, heating the pre-prepared production equipment masterbatch machine, and keeping warm after the production equipment masterbatch machine reaches a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com