Surface treatment method and device treated by surface treatment method

一种表面处理、表面层的技术,应用在处理烃油、处理设备腐蚀/抑制污垢、机械设备等方向,能够解决应力断裂、热疲劳、物理特性不利影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] Example 1BaCe 0.7 Zr 0.3 o 3 powder preparation

[0049] BaCe 0.7 Zr 0.3 o3 Powders are prepared by solid state reaction methods. Stoichiometric high-purity barium carbonate, zirconia, and ceria powders (all from Sinopharm Chemicals Co., Ltd., Shanghai, China) were mixed in ethanol and ball milled for 16 hours. Calcined in air at 1600°C for 2 hours to form BaCe 0.7 Zr 0.3 o 3 powder. The calcined powder was mixed with ethanol and ball milled for 16 hours. BaCe obtained after drying 0.7 Zr 0.3 o 3 Powder (d 50 = 1.5 microns).

example 2

[0050] Example 2 Processing Material Preparation

[0051] BaCe prepared in Example 1 0.7 Zr 0.3 o 3 powder (7.87 g) and 11.93 g CeO 2 The sol (20 wt%, dispersed in water, Alfa Aesar #12730, obtained from Alfa Aesar, Ward Hill, MA, USA) was added to a plastic bottle mounted on a high speed mixing machine. After mixing for 30 minutes, dry with an infrared lamp. The dried powder is pressed into processing tablets.

[0052] Put the treated piece into a tube furnace for vacuum sintering at about 1000°C and then cool to room temperature. The rate of temperature rise and fall in the furnace was about 5°C / minute.

example 3

[0053] Example 3 surface treatment

[0054] The treated sheet obtained in Example 2 was ground with sandpaper and then the powder on its surface was removed with compressed air.

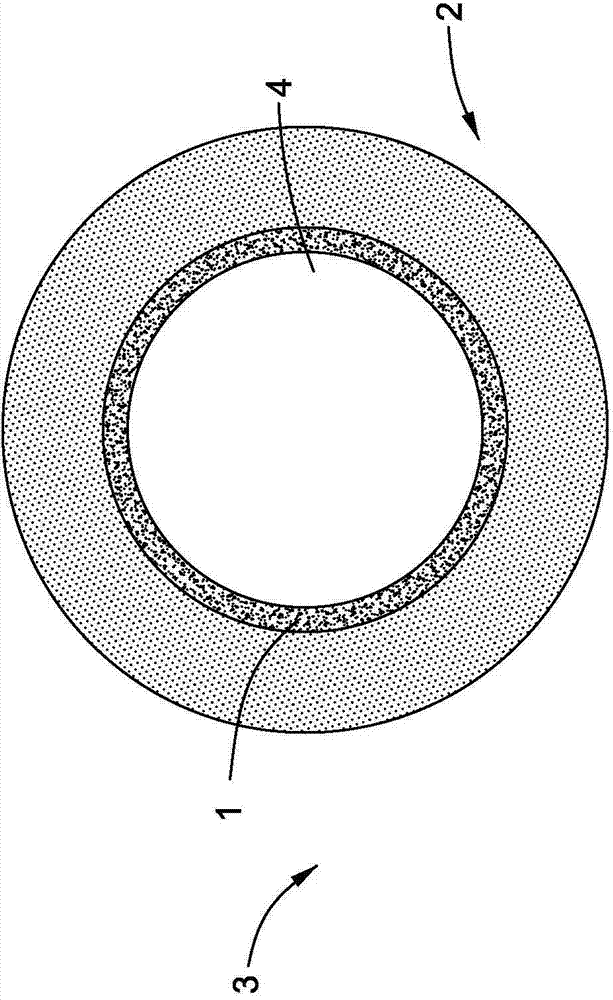

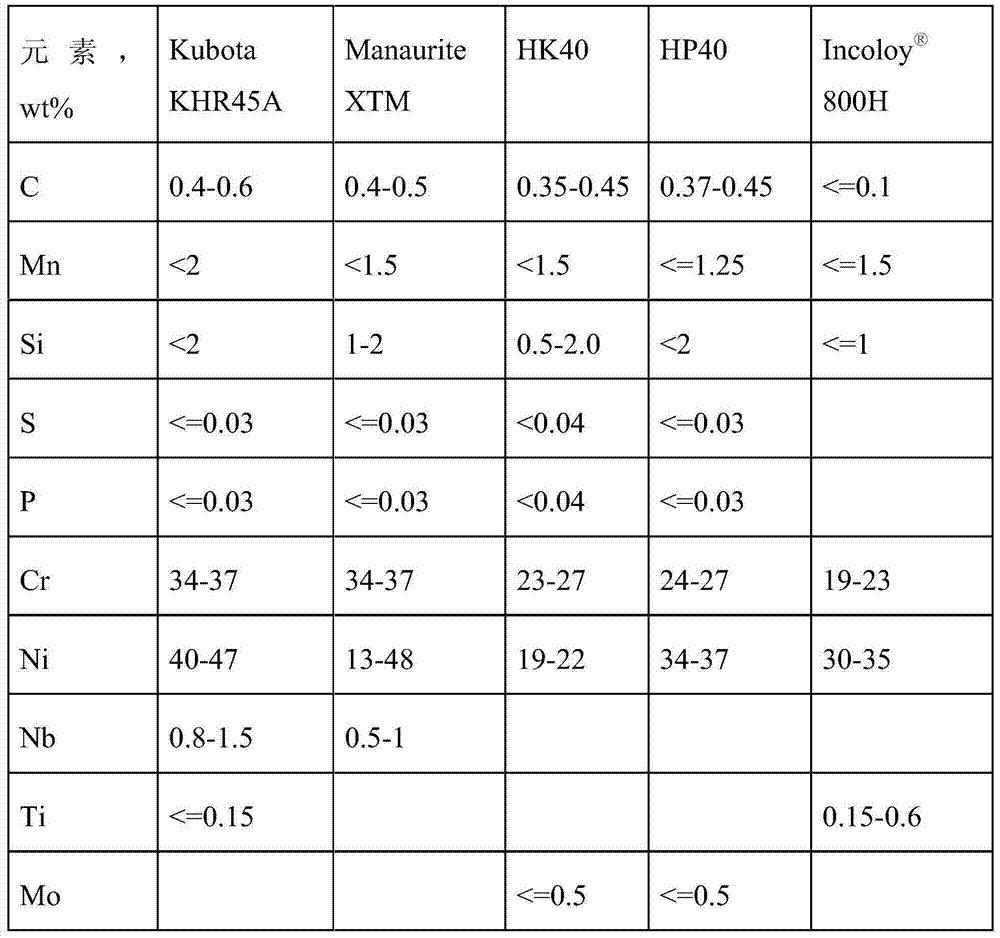

[0055] The substrate material made of Kubota KHR45A alloy was pretreated by sandblasting machine and sandpaper polishing. Then ultrasonically wash in deionized water for 10 minutes, dry with paper, and blow off residual moisture with compressed air.

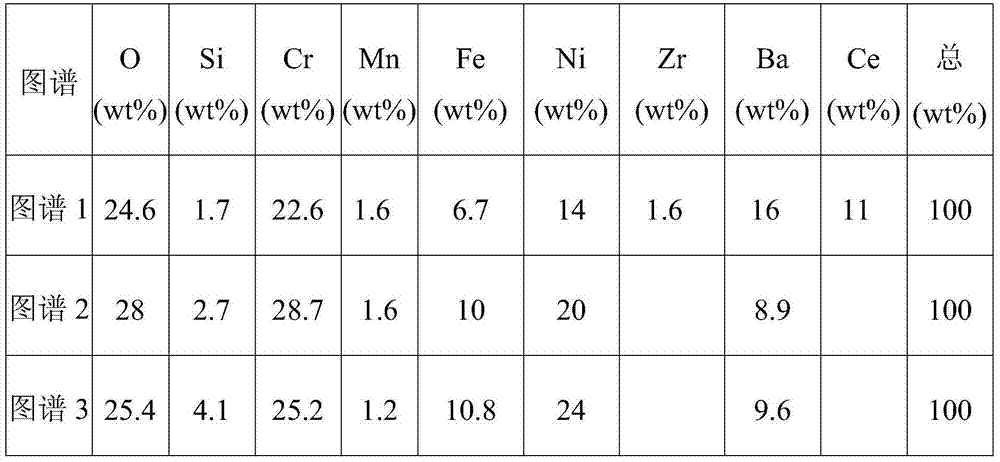

[0056] The treatment sheets are placed on the substrate materials, covering part of the surface of each substrate material. Then put the two together into a tube furnace and treat them at 850°C for 8 hours in an atmosphere of nitrogen and water vapor (the weight ratio of nitrogen to water vapor is 1:1). The energy dispersive spectroscopy (EDS) analysis results shown in Tables 2 and 3 below show that the elements in both the base material and the treatment sheet were formed on the surface of the substrate material contacting the treatment sheet, but on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com