Ethylene copolymer composition and uses thereof

A technology of ethylene copolymers and olefin copolymers, which is applied in the field of ethylene copolymer compositions, and can solve problems such as reduced moldability, unstable bubbles, and low transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

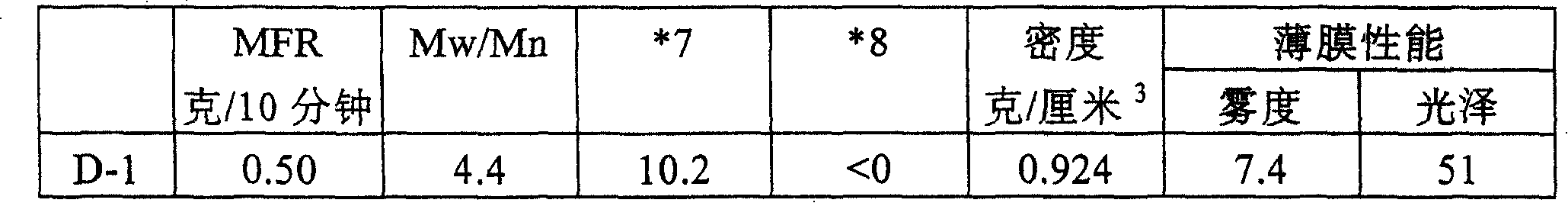

Examples

preparation example Construction

[0328] In the preparation of the prepolymerized catalyst, based on the transition metal atoms in the component (b), the amount of component (b) is usually 10 -6 to 2×10 -2 mol / L solvent, preferably 5×10 -5 to 10 -2 Mole / liter solvent; The consumption of component (b) in 1 gram carrier (c) is 5 * 10 -6 up to 5×10 -4 Mole, preferably 10 -5 to 2×10 -4 Moore. The atomic ratio (Al / transition metal) of aluminum (Al) in component (a) to transition metal in component (b) is generally in the range of 10 to 500, preferably 20 to 200. The atomic ratio (Al-d / Al-a) of the aluminum atom (Al-d) in the optional component (d) to the aluminum atom (Al-a) in the component (a) is generally in the range of 0.02 to 3, preferably 0.05 to 1.5.

[0329] The consumption of solid catalyst component is usually 10% in terms of the transition metal in the transition metal compound -6 to 2×10 -2 mol / L solvent, preferably 5×10 -5 to 10 -2 mol / liter of solvent.

[0330] The prepolymerization temp...

Embodiment

[1112] The present invention is further described with reference to the following examples, but it should be understood that the present invention is not limited by these examples.

[1113] Film properties were evaluated in the following manner.

[1114] Haze

[1115] Haze was measured according to ASTM-D-1003-61.

[1116] luster

[1117] Gloss was measured in accordance with JIS Z8741.

[1118] Dart impact strength

[1119] Dart impact strength was determined according to ASTM D 1709, Method A.

preparation Embodiment 1

[1121] Preparation of Catalyst Components

[1122] 5.0 kg of silica which had been dried at 250°C for 10 hours was suspended in 80 liters of toluene, and the suspension was cooled to 0°C. Then, 28.7 liters of a toluene solution of methylaluminoxane (Al: 1.33 mol / liter) was added dropwise to the suspension over 1 hour. During the dropwise addition, the temperature of the system was kept at 0°C. The reaction was continued at 0°C for 30 minutes. Thereafter, the temperature was raised to 95° C. within 1.5 hours, and the reaction was carried out at this temperature for 20 hours. The temperature was then lowered to 60°C and the supernatant was removed by decanting.

[1123] The resulting solid was washed twice with toluene and then suspended in 80 liters of toluene. At 80°C, within 30 minutes, 20.0 liters of toluene solution (Zr: 14.0 mmol / liter) of bis(methylcyclopentadienyl) zirconium dichloride was added dropwise to the system, and the reaction was continued at 80°C for 2 Ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com