Drying system used in airplane

A drying system and aircraft technology, applied in aircraft parts, air treatment equipment, gas treatment, etc., can solve the problems of increasing aircraft power consumption, increasing aircraft equipment weight, increasing aircraft energy consumption, etc., to reduce fuselage corrosion, Reduces electrical failures and short circuits, and eliminates the effect of condensation or ice accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

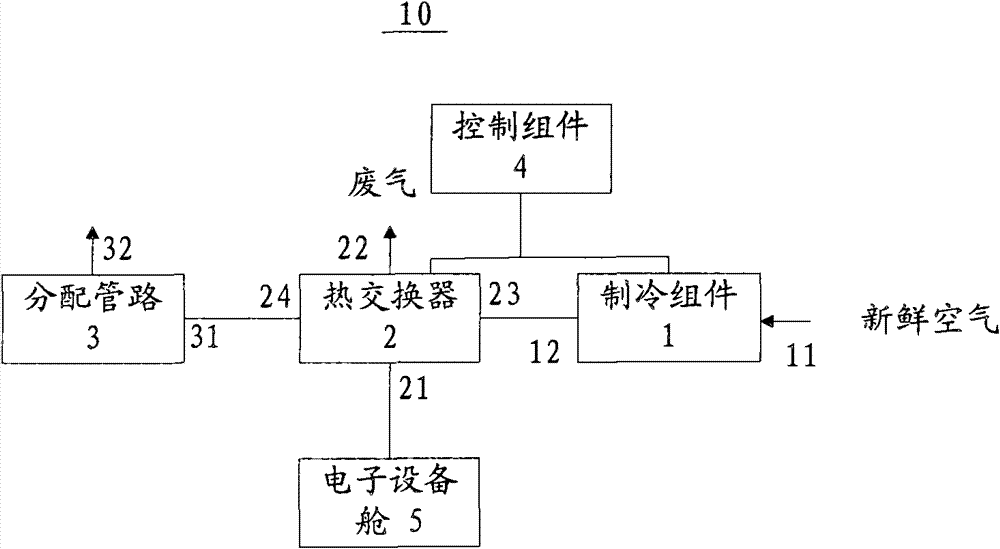

[0014] Such as figure 1 As shown, it shows a schematic diagram of the drying system of the present invention, wherein the drying system 10 is composed of a refrigeration assembly 1 , a heat exchanger 2 , a distribution pipeline 3 and a control assembly 4 . The refrigerating assembly 1 has an air inlet port 11 for the first dehumidification and an air outlet port 12 for the first dehumidification, which are used for performing the first dehumidification of the fresh air entering from the air inlet port 11 for the first dehumidification. Dehumidification thereby reducing its absolute humidity. The heat exchanger 2 has an exhaust gas inlet port 21 , an exhaust gas outlet port 22 , an air inlet port 23 for the second dehumidification, and an air outlet port 24 for the second dehumidification. Wherein, the waste gas inlet port 21 communicates with the electronic equipment compartment 5, the waste gas discharge port 22 communicates with the outside of the aircraft, and the second d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com