Harvester provided with drainage tank

A technology for drainage tanks and harvesters, which is applied to harvesters, agricultural machinery and implements, and other applications. It can solve the problems of electromagnetic switch coil burnout, parts corrosion, and engine life reduction, so as to prolong the service life and reduce labor intensity. , the effect of increasing the driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

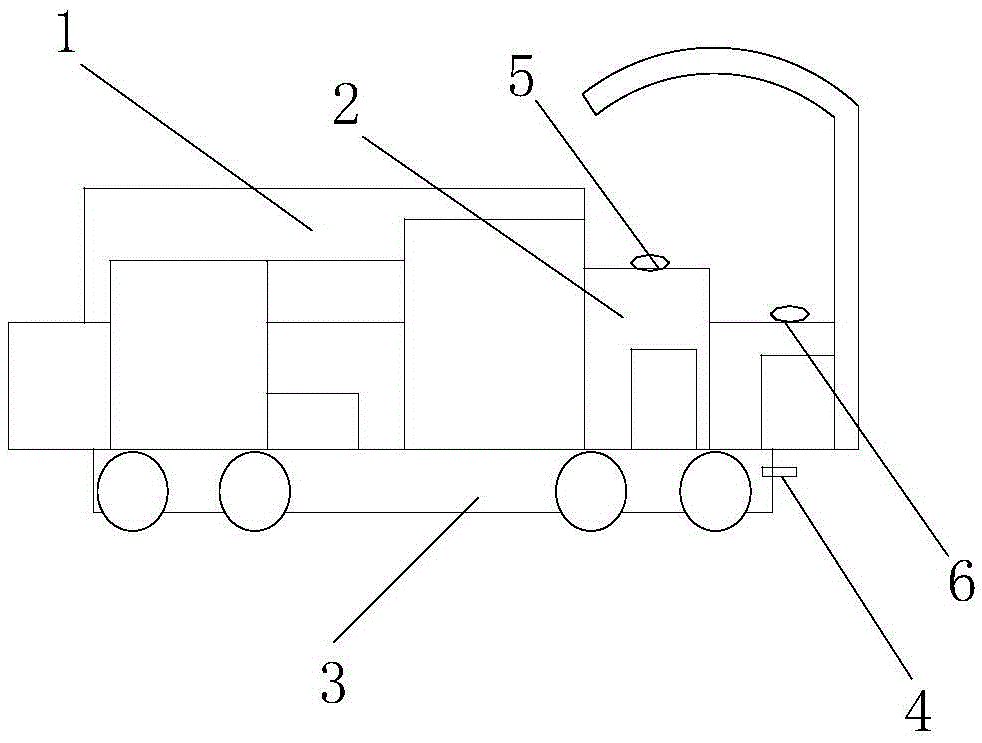

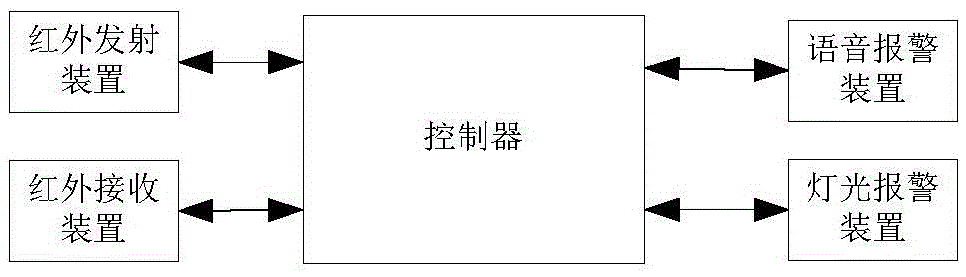

[0030] As shown in the figure, a harvester provided with a drainage tank provided in this embodiment includes a working room 1, a cab, a walking device 3, a distance detector 4, a turning indicator 5 and a controller 6;

[0031] The working room includes a working room main body 2, a threshing bin, a storage bin, a material inlet and a material outlet; The bin is located in the main body of the working room, the threshing bin and the storage bin are connected by a conveyor belt, and the walking device is set on both sides of the main body of the working room;

[0032] The cab includes a cab main body, a console, a steering wheel, an engine and a driver's seat. The console is arranged at the left end of the cab main body, the steering wheel is arranged on the console, the engine is arranged at the bottom of the console, and the driver's seat is arranged at the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com